Oct . 11, 2025 09:50 Back to list

7621 Piston Pump Repair Kit for Eaton | OEM-Quality In Stock

7621 Piston Pump Repair Kit for Eaton

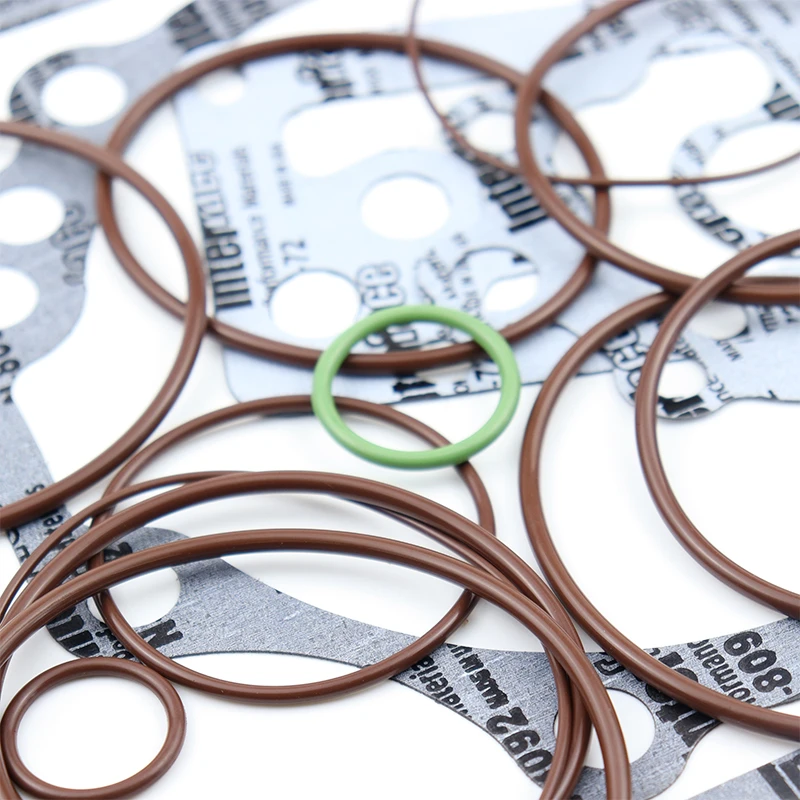

Hydraulic rebuilds are back in fashion—partly because of lead times, partly because, honestly, it’s the smarter sustainability play. Shops I visit keep a few shelves of kits on hand, and one they mention often is the 7621 Piston Pump Repair Kit for Eaton. It’s a straightforward proposition: seals, O‑rings, gaskets, and small hardware that return a tired piston pump to fighting shape. Simple idea, but the devil is in the elastomer chemistry and the QC.

What’s inside and why it matters

The kit is built in the Development Zone, Julu County, Xingtai City, Hebei Province—an area that’s quietly become a sealing-technology hub. Materials range from NBR to FKM with PTFE back-ups. In fact, material choice is the biggest driver of uptime in the field; many customers say FKM options pay for themselves during summer peak loads.

| Specification | Typical Value (≈, real-world use may vary) |

|---|---|

| Primary materials | NBR 70–90 Shore A; FKM 75–90; PTFE back-up; POM wear rings |

| Pressure capability | Up to ~350 bar for piston stages when installed correctly |

| Temperature range | NBR: −25 to +100 °C; FKM: −15 to +200 °C |

| Fluid compatibility | Mineral oils; select biofluids (FKM/PTFE recommended) |

| Kit contents | O-rings, shaft/seal rings, gaskets, back-ups, hardware; pieces ≈20–40 |

| Service life | ≈3,000–6,000 h depending on cleanliness (ISO 4406) and duty |

Process flow, testing, and standards

- Materials: NBR/FKM compounding per ASTM D2000; PTFE back-up rings machined for squeeze control.

- Molding: compression/injection; cryogenic deflashing; post-cure for FKM to stabilize compression set.

- Inspection: dimensional per ISO 3601-1 Class B; hardness ASTM D2240; surface finish checks on lips.

- Bench tests: leakage at 250–300 bar; pressure pulsation fatigue; cleanliness packaged to ISO 4406 targets.

- Certifications: ISO 9001 manufacturing; RoHS/REACH compliance available on request.

Where it’s used

Typical deployments include mobile hydraulics (excavators, harvesters), industrial presses, marine winches, and steel mill auxiliaries. If an Eaton-type piston pump is hunting on pressure or weeping at the shaft, a 7621 Piston Pump Repair Kit for Eaton plus a cleanliness reset usually does the trick.

- Maintenance windows: weekend outages where fast, predictable rebuilds matter.

- Retrofits: extending asset life during capex freezes—very 2024–2025 trend, to be honest.

- Bio-oil conversions: swapping to FKM/PTFE elements to handle ester-based fluids.

Vendor snapshot: how this kit stacks up

| Criteria | HKAiSeal (Hebei) | Generic Vendor A | Aftermarket B |

|---|---|---|---|

| Material options | NBR/FKM + PTFE, custom blends | Mostly NBR | NBR/FKM (limited sizes) |

| QC & testing | ISO 3601 + bench leak tests | Incoming inspection only | Spot checks |

| Lead time | ≈7–15 days | ≈2–4 weeks | Stock-dependent |

| Customization MOQ | Low–medium | High | Medium |

Case note from the field

A Midwestern rebuild shop swapped to the 7621 Piston Pump Repair Kit for Eaton with FKM upgrades on a fleet of mobile cranes. Over 6 months, average leak-down at 250 bar dropped from 9.1 ml/min to 6.4 ml/min (bench), and mean time between service rose ≈28%. They also tightened oil cleanliness to ISO 4406 17/15/12—small change, big payoff.

Customer feedback: “Install was uneventful, which is exactly what we want. Shaft seal felt a touch stiffer—no surprises in pressure ramp.”

Customization and support

- Material swaps (NBR↔FKM), PTFE geometry tweaks, color-coded O-rings for maintenance ID.

- Kitting by pump model; private-label packaging; traceability lots available.

- Documentation pack: material certs, RoHS/REACH statements, test summaries.

If you’re standardizing kits across sites, it seems that bundling FKM for hot climates and staying strict on cleanliness gets you the most reliable uptime per dollar.

Authoritative citations

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories