- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 17, 2025 15:21 Back to list

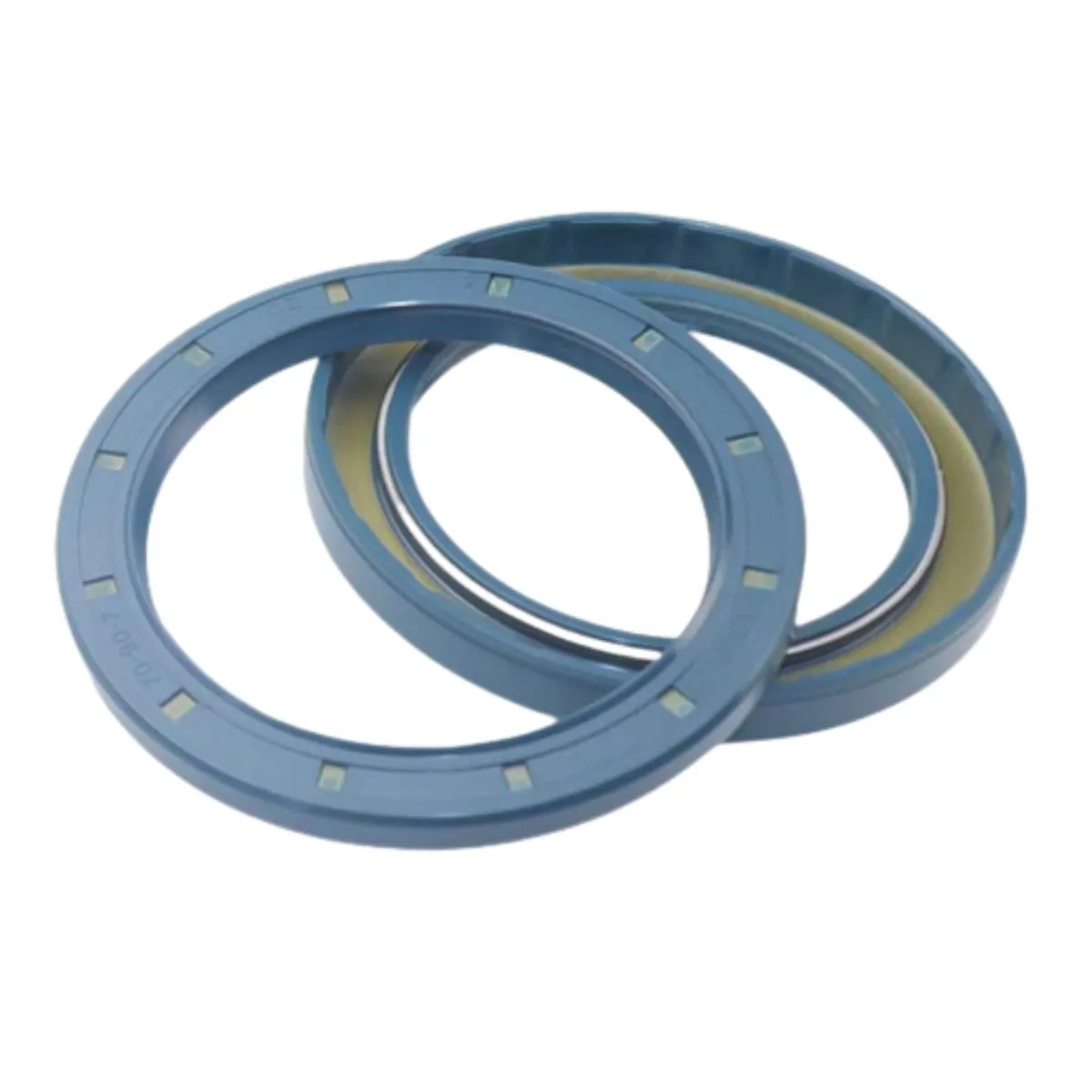

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

Tcv Oil Seal is a key solution in the Mechanical equipment manufacturing industry, specifically within Manufacturing of hydraulic and pneumatic power machinery and components and Seal manufacturing. This article explores how Hebei Hankai Machinery Equipment Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Tcv Oil Seal Overview

- Benefits & Use Cases of Tcv Oil Seal in Seal manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Mechanical equipment manufacturing industry

- Conclusion on Tcv Oil Seal from Hebei Hankai Machinery Equipment Co., Ltd.

Tcv Oil Seal Overview

A Tcv Oil Seal (also seen as oil seal tcv or tcv seal) is a high-performance rotary shaft seal designed to retain lubricants and exclude contaminants in hydraulic and pneumatic power machinery. The TCV structure typically features a reinforced metal case, a primary sealing lip energized by a garter spring for stable radial load, and a secondary dust lip that blocks external ingress. This double-lip configuration is engineered for demanding duty cycles where pressure fluctuations, micro-shaft runout, and vibration can challenge standard designs.

From a technical standpoint, materials are selected to match medium, temperature, and pressure: NBR for general oils and diesel at moderate temperatures; HNBR for improved heat/ozone resistance; and FKM (Viton) for higher temperatures and aggressive fluids. Precision chamfers, correct bore interference, and shaft finishes (typically Ra ≈ 0.2–0.8 μm with appropriate hardness) are recommended to ensure optimal sealing life. Hebei Hankai Machinery Equipment Co., Ltd. manufactures the Tcv Oil Seal to tight tolerances, offering customizable sizes, materials, and spring configurations for OEM and MRO needs across pumps, motors, gearboxes, and hydraulic power units in the seal manufacturing value chain.

Benefits & Use Cases of Tcv Oil Seal in Seal manufacturing

In seal manufacturing for hydraulic and pneumatic equipment, the Tcv Oil Seal is the go-to choice for rotary interfaces exposed to pressure pulses and contamination. Typical applications include hydraulic pumps and motors, transmission and gear reducers, power packs, mobile hydraulics (excavators, loaders), and compressor drives. The TCV profile’s dust lip provides robust ingress protection, while the spring-loaded primary lip maintains contact under shaft eccentricity and thermal expansion—helping to stabilize leakage performance throughout the service interval.

Key advantages for B2B buyers include consistent sealing at higher differential pressures compared to basic profiles, extended service life via optimized lip geometry, and material options that resist swelling, heat, and chemical attack. Hebei Hankai Machinery Equipment Co., Ltd. brings deep application know-how—from compound selection to lip design optimization—so OEMs can tune friction, wear, and pressure capability for their platforms. Whether you specify an oil seal tcv for a compact, high-speed gearbox or a rugged tcv seal for off-highway hydraulics, engineered variants are available to meet durability, cleanliness, and uptime targets.

Cost, Maintenance & User Experience

Total cost of ownership hinges on uptime and maintenance frequency. By pairing an engineered lip profile with the right elastomer and spring force, the Tcv Oil Seal can reduce unplanned stoppages and oil top-ups—improving MTBR and delivering measurable ROI over the lifecycle of hydraulic power machinery. Standardization across sizes and compounds helps consolidate inventory, while drop-in interchangeability simplifies MRO workflows and shortens downtime windows for fleet operators and factories alike.

Best practices for installation include using a lead-in chamfer and installation sleeve, pre-lubricating the lip, orienting the dust lip outward, and verifying shaft finish and hardness. Users in the Manufacturing of hydraulic and pneumatic power machinery and components sector consistently value predictable leakage control, clean operation, and stable torque/friction characteristics—all areas where Hebei Hankai Machinery Equipment Co., Ltd.’s Tcv Oil Seal is designed to perform. Technical support, rapid sampling, and application guidance further enhance the user experience during design-in and field deployment.

Sustainability & Market Trends in Mechanical equipment manufacturing industry

Precision sealing plays a strategic role in sustainability by preventing fluid losses, maintaining energy efficiency, and extending component life. In many markets, environmental directives and customer ESG goals are accelerating the shift to longer-life seals, lower fugitive emissions, and materials compatible with bio-based or fire-resistant fluids. The Tcv Oil Seal supports these objectives by delivering reliable sealing performance that helps minimize lubricant consumption and maintenance-related waste—key levers in lowering total environmental impact.

Industry trends point to higher power density, compact footprints, and elevated operating temperatures, all of which demand advanced compounds (e.g., HNBR, FKM) and robust lip designs. Digitalization and condition-based maintenance also favor seals with predictable wear behavior and stable friction characteristics. Hebei Hankai Machinery Equipment Co., Ltd. is aligning with these trends through material engineering, precision tooling, and responsive production—positioning its tcv seal portfolio as an eco-conscious, future-ready choice for OEMs and MROs scaling up reliability while meeting regulatory expectations.

Conclusion on Tcv Oil Seal from Hebei Hankai Machinery Equipment Co., Ltd.

For B2B decision makers in the Mechanical equipment manufacturing industry—especially across Manufacturing of hydraulic and pneumatic power machinery and components and Seal manufacturing—the Tcv Oil Seal offers dependable leakage control, long service life, and flexible material options. Backed by Hebei Hankai Machinery Equipment Co., Ltd.’s engineering support and manufacturing rigor, it helps OEMs and operators achieve uptime, cleanliness, and sustainability goals across diverse applications.

- Contact us: email: admin@hkaseal.com

- Visit our website: https://www.hkaiseal.com

- Explore the product page: Standard High-Pressure TCV Type Hydraulic Oil Seal

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

-

Expert Tips on Hydraulic Seal Replacement for Industrial Equipment

NewsNov.17,2025

Products categories