Mar . 04, 2025 03:25 Back to list

cfw oil seal

Industries that utilize the 50x65x8 oil seal often highlight its role in preventing contamination. In agricultural machinery, for example, this seal effectively safeguards internal components from dust, dirt, and debris, which are common in field environments. Meanwhile, in automotive applications, it ensures that lubricants remain within the confines of the gearbox or engine, enhancing maintenance intervals and reducing the risk of costly repairs. End-users frequently attest to the reliability and effectiveness of oil seals when sourced from reputable manufacturers. These seals undergo rigorous testing to ensure they meet stringent international standards. Certification and quality assurance from a trusted supplier add an additional layer of reliability, giving industries the confidence to rely on these components even in the most challenging operational environments. When purchasing oil seals, it's crucial to consider the supplier's reputation and the availability of technical support. Leading manufacturers often offer comprehensive guides and expert advice to aid in the selection process, ensuring clients receive the most suitable seal for their specific application. Additionally, after-sales support, such as installation tips and troubleshooting assistance, further exemplifies a supplier's commitment to quality and customer satisfaction. In conclusion, the 50x65x8 oil seal is more than just a component; it is a critical part of ensuring machinery operates efficiently and effectively. Its design, material selection, and construction are all aimed at providing a solution that withstands the demands of various industrial applications. By understanding its role and importance, businesses can make informed decisions that enhance their equipment's performance and longevity, ultimately leading to increased operational efficiency and profitability.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

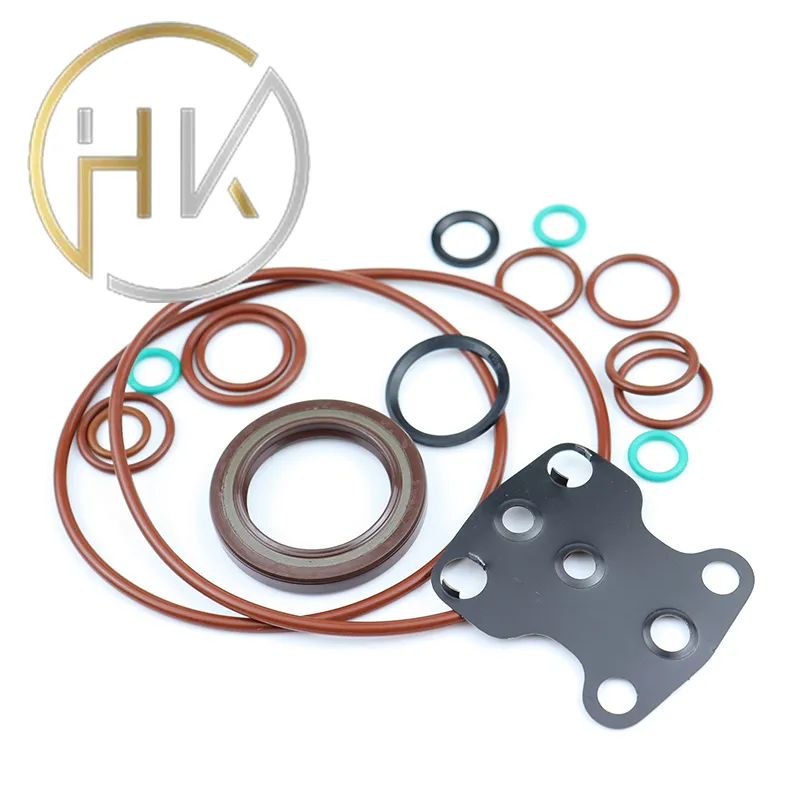

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories