Oct . 20, 2025 12:20 Back to list

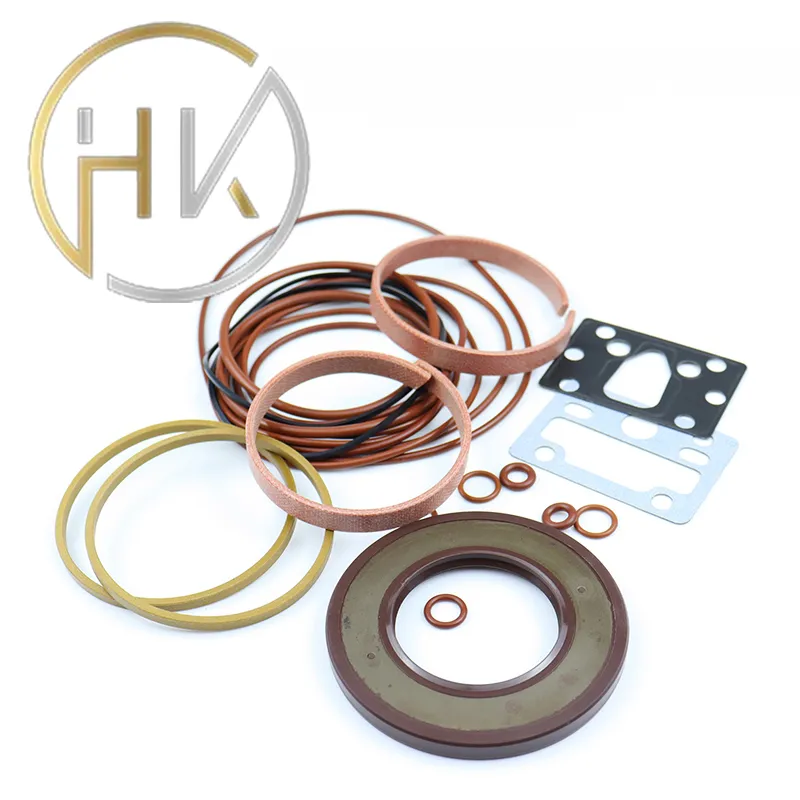

Wholesale Hydraulic Pump Seal Kits A4VG71 - Leak-Proof OEM

Field Notes: What’s Behind Reliable A4VG71 Pump Seal Kits

If you’ve ever nursed a leaking axial piston pump through a busy season, you know why Wholesale Hydraulic Pump Seal Kits A4VG71 matter. In real life, downtime doesn’t negotiate. This kit—assembled in the Development Zone, Julu County, Xingtai City, Hebei Province—targets fast, predictable repair of A4VG71-class pumps used across mobile hydraulics, construction, and quarrying. To be honest, the market has shifted: buyers now ask for traceability and test data, not just “NBR + FKM” on a quote sheet.

Industry pulse and why it matters

We’re seeing tighter cleanliness requirements (ISO 4406 awareness is way up), plus more FKM + PTFE blends to hold up against bio-hydraulic fluids and higher temperature cycles. Many customers say the new-gen kits last ≈15–25% longer when pumps are assembled in a clean bay and lubricated properly. I guess that’s not surprising—seal geometry and compound consistency have improved a lot.

Key specifications

| Parameter | Spec (≈ / typical) |

|---|---|

| Seal Materials | NBR (≈70–90 Shore A), FKM (≈75–90 Shore A), PTFE backup rings; optional HNBR |

| Fluid Compatibility | Mineral oils, select bio-oils, HVLP/HLP; check ester-based fluids case-by-case |

| Pressure/Temp Window | Up to 350 bar dynamic; −30 to +120 °C (NBR); up to +200 °C (FKM) in short duty |

| Tolerances | Meets DIN 3760 / ISO 6194 profiles; lip runout and ID interference checked per lot |

| Cleanliness | Packaged to support ISO 4406 18/16/13 assembly targets (real-world use may vary) |

| Contents | O-rings, shaft seals, dust rings, backup rings, wear items matched to A4VG71 layout |

Process flow and testing (the short tour)

Materials: high-consistency NBR/FKM compounds (ASTM D2000 grades), PTFE backups; steel garter springs with anti-corrosion finish.

Methods: CNC-trimmed lips, controlled vulcanization, post-cure for FKM, 100% visual plus random dimensional checks, packaged in low-particulate sleeves.

Testing: hardness (ISO 48-4), swelling (ASTM D471), compression set (ASTM D395), lip torque/friction, and bench-run to 1,000 h with 0–320 bar cycling; typical leakage ≤2 ml/min at 80 °C on new shafts. Service life in the field? Around 4,000–6,000 h if oil cleanliness and shaft finish are within spec.

Where it’s used and why

Applications: excavators, wheel loaders, agricultural sprayers, road pavers, drilling rigs, and industrial power units. Advantages many maintenance managers point out: predictable fit, steady lip preload, good behavior with HLP46 at summer temps, and packaging that doesn’t shed dust (sounds small, actually not).

Vendor comparison (quick glance)

| Vendor | Compound Consistency | Traceability | Lead Time |

|---|---|---|---|

| Wholesale Hydraulic Pump Seal Kits A4VG71 supplier | Tight batch-to-batch; FKM post-cure documented | Lot codes + test sheets | ≈7–15 days ex-works |

| Generic import | Variable; occasional hardness drift | Limited | ≈10–25 days |

| OEM brand | High and very stable | Full serial trace | Stock-dependent; price premium |

Customization and a quick case

Customization: mixed-material kits (FKM on high-heat locations, NBR elsewhere), oversized ID for worn shafts, PTFE energizers, and packaging to meet your cleanroom policy. Certifications typically available: ISO 9001; RoHS/REACH conformity statements on request.

Case study: a quarry fleet retrofitted Wholesale Hydraulic Pump Seal Kits A4VG71 on six loaders. Post-repair oil analysis kept ISO 4406 ≤ 19/17/14; after 1,800 h, observed weepage was negligible, and no unplanned pump pulls. Maintenance lead said the install felt “forgiving” on the first attempt—good sign.

Final notes

If you’re rebuilding A4VG71-class pumps, this kit checks the technical boxes without drama. Just mind the basics: shaft surface Ra, correct lubricant at assembly, and cleanliness. For sourcing direct from the Development Zone, Julu County, Xingtai City—pricing is sensible, and lead times are, well, refreshingly normal.

Authoritative citations

- ISO 6194 / DIN 3760: Rotary shaft lip seals — design and dimensions.

- ISO 4406:2017: Hydraulic fluid power — Fluids — Method for coding the level of contamination by solid particles.

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications.

- ASTM D471: Standard Test Method for Rubber Property—Effect of Liquids.

- EU REACH (EC) No 1907/2006 and RoHS 2011/65/EU compliance guidance for elastomeric parts.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories