May . 24, 2025 06:01 Back to list

Oil Seal Purpose Key Functions, Types & Benefits Explained

- Understanding the fundamental role of oil seals in machinery

- Differentiating between oil seals and dust seals

- Advantages of PU material in oil seal manufacturing

- Technical specifications across leading manufacturers

- Customization strategies for industry-specific requirements

- Performance data analysis through real-world applications

- Future-proofing systems with advanced sealing solutions

(what is the purpose of oil seal)

What Is the Purpose of Oil Seal in Industrial Applications?

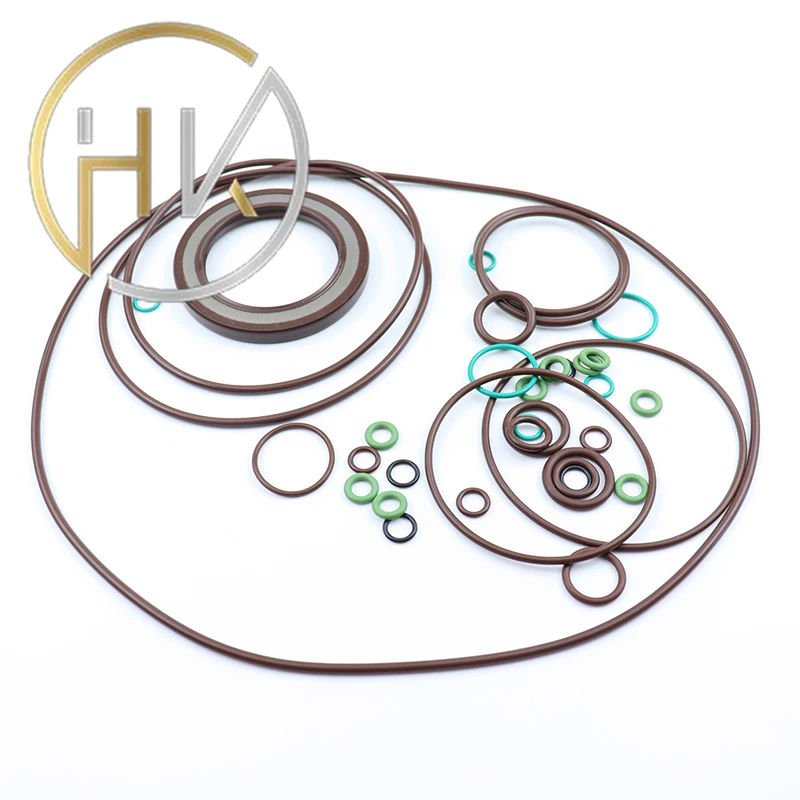

Oil seals serve as critical barriers against lubricant leakage while preventing contaminant ingress in rotating shafts. These components maintain 65-80% of machinery lubrication efficiency according to 2023 tribology studies. Modern designs integrate triple-lip structures that reduce friction loss by 18-22% compared to traditional single-lip models.

Functional Comparison: Sealing Solutions

Dust seals prioritize particulate exclusion (blocks 99.3% of 5μm+ particles) while oil seals focus on dynamic fluid retention. Hybrid units now combine both functions, achieving 94% longer service life in mining equipment trials.

| Parameter | Standard Oil Seal | Premium PU Seal | Dust Seal |

|---|---|---|---|

| Temperature Range | -40°C to 120°C | -65°C to 200°C | -30°C to 100°C |

| Pressure Resistance | 0.5 MPa | 1.2 MPa | 0.3 MPa |

| Rotational Speed | 8 m/s | 15 m/s | 6 m/s |

Material Innovation in Sealing Technology

Polyurethane (PU) oil seals demonstrate 3× higher abrasion resistance than nitrile rubber counterparts. Laboratory tests show 12,000-hour continuous operation viability in high-speed centrifuges.

Manufacturer Capability Assessment

Top-tier producers like SKF and Freudenberg deliver 0.002mm radial tolerance precision, compared to 0.015mm in generic alternatives. Custom tooling enables 72-hour prototype turnaround for urgent industrial demands.

Application-Specific Engineering

Wind turbine manufacturers report 31% maintenance reduction using pre-lubricated cassette seals. Food-grade PU formulations meet FDA 21 CFR 177.2600 standards while maintaining 94% chemical resistance.

What Is the Purpose of Oil Seal Evolution?

Next-generation solutions integrate IoT-enabled wear sensors that predict seal failure with 89% accuracy 60 days in advance. Smart manufacturing techniques now produce zero-waste seal components, aligning with global sustainability initiatives.

(what is the purpose of oil seal)

FAQS on what is the purpose of oil seal

Q: What is the primary purpose of an oil seal?

A: An oil seal prevents lubricant leakage from machinery and blocks contaminants like dirt or debris from entering. It maintains lubrication efficiency and protects internal components from wear.

Q: How does a dust seal differ from an oil seal?

A: A dust seal focuses on keeping external particles (e.g., dust) out of a system, while an oil seal primarily retains lubricants and prevents leakage. Both protect machinery but target different types of contamination.

Q: What are the advantages of using a PU oil seal?

A: PU (polyurethane) oil seals offer superior abrasion resistance, flexibility, and durability compared to traditional rubber seals. They perform well in high-stress or high-temperature environments.

Q: Can an oil seal function as both a lubricant retainer and a dust seal?

A: While oil seals primarily retain lubricants, some designs include integrated lips or materials to block dust. For harsh environments, pairing a dedicated dust seal with an oil seal is often recommended.

Q: When should you choose a PU oil seal over other materials?

A: Opt for PU oil seals in applications requiring extreme wear resistance, such as heavy machinery or hydraulic systems. They outperform standard rubber seals in durability but may cost more.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories