Dec . 10, 2024 09:17 Back to list

seal kit hydraulic pump

Understanding Seal Kit Hydraulic Pumps

Hydraulic systems are essential in various industries, including construction, manufacturing, and automotive. Among the critical components of these systems are hydraulic pumps, which convert mechanical energy into hydraulic energy. A vital aspect of hydraulic pump maintenance and efficiency is the seal kit. This article aims to provide insights into seal kit hydraulic pumps, their importance, components, and maintenance considerations.

What are Seal Kit Hydraulic Pumps?

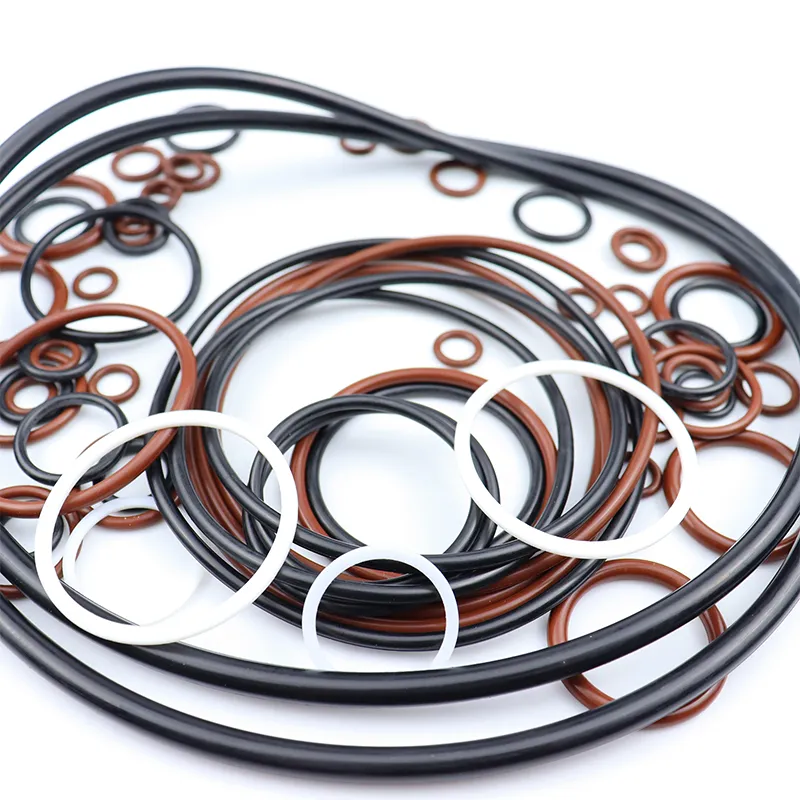

A hydraulic pump is a mechanical device that moves fluids by converting rotational energy into hydraulic energy. Seal kits are collections of components designed to ensure the effective functioning and longevity of hydraulic pumps. They primarily include seals, o-rings, backup rings, and gaskets, which are crucial for preventing leaks and maintaining pressure within the system.

Seal kits are specifically designed for various types of hydraulic pumps, including gear pumps, piston pumps, and vane pumps. The seals in these kits are made from materials such as rubber, polyurethane, or PTFE (Teflon), chosen for their durability and resistance to pressure, temperature, and chemical exposure.

Importance of Seal Kits in Hydraulic Pumps

The primary function of a seal kit in a hydraulic pump is to maintain the integrity of the hydraulic system by preventing fluid leakage. This is crucial for several reasons

1. Efficiency Leaks can lead to a loss of hydraulic fluid, resulting in decreased efficiency. A well-sealed hydraulic pump can maintain optimal pressure and performance.

2. Safety Hydraulic fluid leaks can create hazardous working conditions, especially in industrial settings. Seal kits help mitigate these risks by ensuring a secure system.

3. Cost-Effectiveness Regular maintenance and replacement of seal kits can lead to significant cost savings. By preventing leaks and maintaining proper function, businesses can avoid costly repairs and downtime caused by hydraulic system failures.

4. Longevity The proper functioning of seals prolongs the life of hydraulic pumps. By minimizing wear and tear on internal components, seal kits contribute to the overall durability of the hydraulic system.

Components of a Seal Kit

A typical seal kit will include several essential components

1. Seals These prevent fluid from escaping the pump housing. They are typically placed on the shaft or between components.

seal kit hydraulic pump

3. Backup Rings These are used in conjunction with seals to prevent seal extrusion and are particularly useful in high-pressure applications.

4. Gaskets These flat seals sit between two mating surfaces to prevent leaks.

Understanding the purpose and function of each component helps in the effective maintenance of hydraulic pumps.

Maintenance Considerations

Proper maintenance of a hydraulic pump and its seal kit is crucial for its effective operation. Here are some key maintenance tips

1. Regular Inspections Regularly check seals and o-rings for signs of wear or damage. Early detection can prevent catastrophic failures.

2. Fluid Quality Ensure that the hydraulic fluid used is clean and the appropriate type for the system. Contaminated hydraulic fluid can degrade seals and other components.

3. Temperature Control Monitor the operating temperature of the hydraulic system. Excessive heat can lead to premature seal failure.

4. Storage of Seal Kits If storing seal kits for future use, keep them in a cool, dry place, away from direct sunlight to prevent degradation of materials.

5. Follow Manufacturer Guidelines Always adhere to the manufacturer’s recommendations for installation and maintenance intervals for seal kits.

Conclusion

Understanding seal kit hydraulic pumps is vital for anyone working with hydraulic systems. By recognizing the importance of seal kits, knowing their components, and adhering to maintenance protocols, users can ensure the longevity and efficiency of their hydraulic pumps. Investing in proper seal kit maintenance ultimately enhances safety, improves efficiency, and saves costs, proving that good practices in hydraulic system management yield significant long-term benefits.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories