Dec . 10, 2024 09:30 Back to list

45x62x8 oil seal

The Importance of Quality Oil Seals A Deep Dive into the 45x62x8 mm Specification

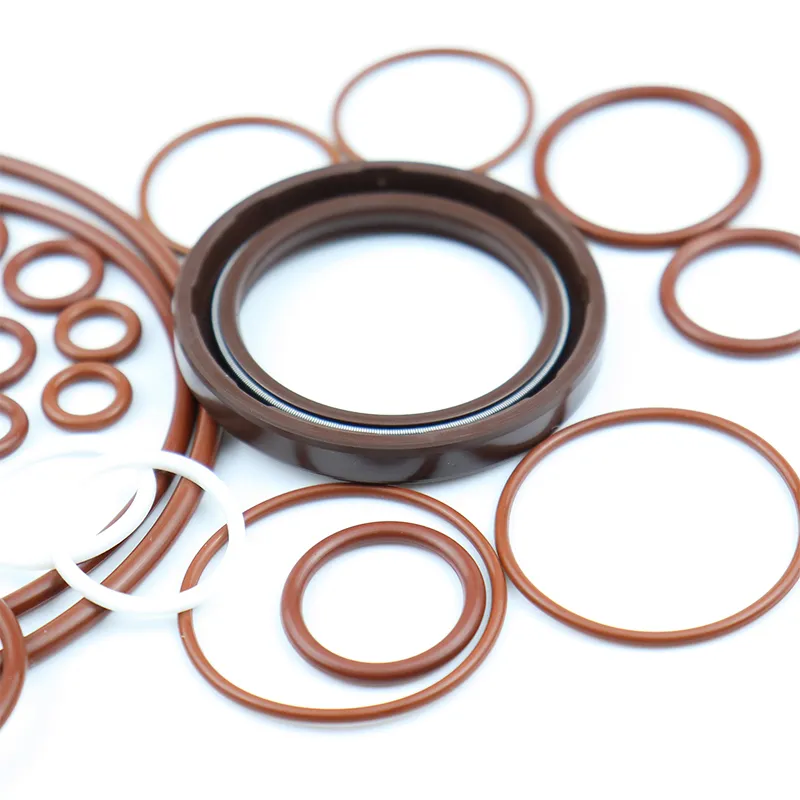

When it comes to industrial machinery and automotive applications, the importance of quality oil seals cannot be overstated. Among various specifications, the 45x62x8 mm oil seal stands out as a commonly used size that serves various critical purposes. In this article, we will explore what oil seals are, the significance of the 45x62x8 mm specification, and why choosing high-quality options is paramount for performance and longevity.

What Are Oil Seals?

Oil seals, also known as lip seals or rotary shaft seals, are mechanical components designed to retain lubricants and prevent contaminants from entering machinery. Typically made of rubber or other elastomeric materials, oil seals possess a unique design that includes a sealing lip and a metal case. The sealing lip, which is in contact with the rotating shaft, deforms slightly to create a tight seal that can withstand pressure while allowing for smooth rotational movement.

The 45x62x8 mm Specification

The numerical designation of the oil seal—45x62x8 mm—denotes its dimensions in millimeters. Specifically, the first number (45 mm) represents the inside diameter, the second number (62 mm) indicates the outside diameter, and the last number (8 mm) specifies the width of the seal. This particular size is prevalent in a wide range of applications, such as automotive engines, gearboxes, and hydraulic systems.

What makes the 45x62x8 mm oil seal particularly beneficial is its compatibility with various shaft sizes and housing setups. The versatility of this specification ensures that it can be utilized across different industries, making it a staple in both mechanical and automotive engineering.

Key Benefits of Using Quality Oil Seals

1. Leak Prevention One of the primary functions of an oil seal is to prevent leakage of lubricants from machinery. An effective seal minimizes wear and tear by ensuring that the necessary lubrication remains contained within the system, which is crucial for maintaining operational efficiency.

45x62x8 oil seal

2. Contaminant Exclusion In addition to retaining lubricants, quality oil seals also serve as barriers against dust, dirt, and other contaminants. This protective feature is essential for prolonging the lifespan of components and reducing the risk of mechanical failures due to foreign materials entering vital areas.

3. Energy Efficiency A proper seal helps maintain consistent pressure within the system, reducing energy loss caused by leaking fluids. This efficiency results in lower operational costs and improved performance, particularly in machines that rely heavily on lubricants for smooth operation.

4. Longevity and Reliability High-quality oil seals are manufactured from durable materials that can withstand varying temperatures, pressures, and chemical exposures. Choosing a well-made seal ensures that it can perform effectively over time, reducing the need for frequent replacements and maintenance.

Choosing the Right Oil Seal

When selecting an oil seal, factors such as material, temperature range, and compatibility with the specific application must be considered. For the 45x62x8 mm specification, options are available in various materials including nitrile rubber, fluorocarbon, and silicone, each offering unique advantages depending on the operating environment.

Additionally, proper installation is critical to the effectiveness of an oil seal. Ensuring that the seal is aligned correctly and seated firmly will mitigate the risk of leaks and failures, allowing the machinery to operate smoothly.

Conclusion

In summary, the 45x62x8 mm oil seal plays an essential role in the functionality of machinery across various sectors. Its effectiveness in preventing leaks and excluding contaminants contributes to the overall performance and longevity of mechanical systems. Investing in high-quality oil seals ensures reliability, energy efficiency, and reduced maintenance costs—benefits that are vital in today's competitive industrial landscape. As machinery continues to advance, the importance of reliable components such as oil seals will only grow, making it imperative for engineers and operators to prioritize quality and performance in their selection processes.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories