Nov . 19, 2024 14:39 Back to list

Hydraulic Seal Kits for Enhanced Performance and Reliability in Equipment Maintenance

Understanding Seal Kits for Hydraulic Systems

When it comes to hydraulic systems, the integrity of the components involved is crucial for efficient operation. One essential component in these systems is the seal kit, which plays a vital role in maintaining pressure and preventing leaks. This article will explore seal kits for hydraulic applications, their components, types, and importance in various industries.

What is a Seal Kit?

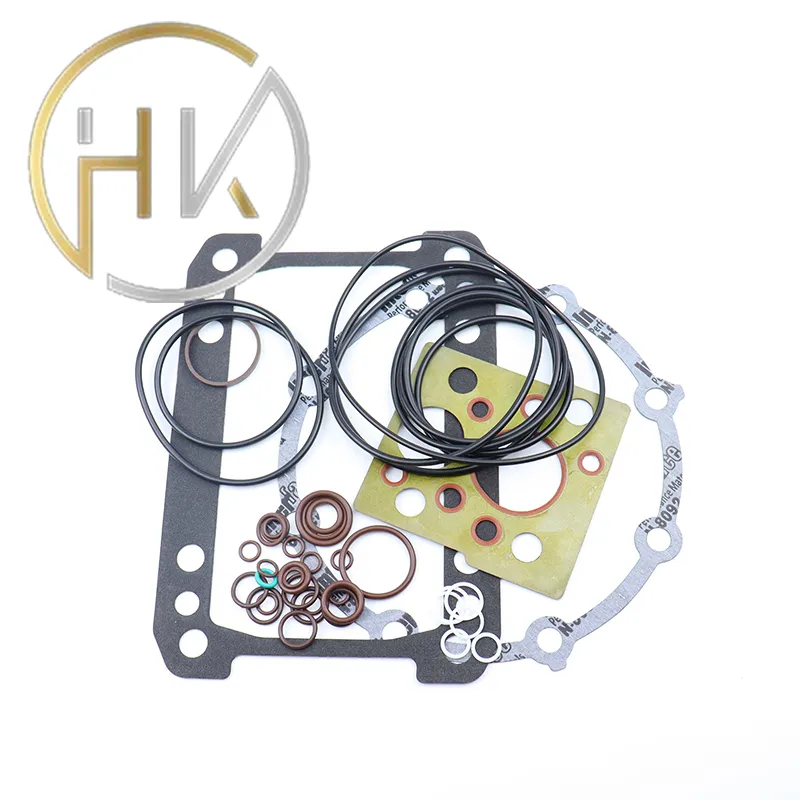

A seal kit is a comprehensive package that contains various sealing components needed to assemble or repair hydraulic cylinders, pumps, or other hydraulic equipment. These kits typically include different types of seals, such as O-rings, hydraulic seals, backup rings, and wipers, designed to provide leakage prevention and ensure smooth operation under high pressure.

Components of Hydraulic Seal Kits

1. O-Rings These are circular rings made from rubber or elastomers that create a secure seal in hydraulic systems. They are commonly used in static and dynamic applications and prevent hydraulic fluid from leaking.

2. Rod Seals Designed to seal the space between the rod and the cylinder wall, rod seals maintain the hydraulic fluid inside the cylinder while allowing the rod to extend and retract smoothly.

3. Piston Seals These seals are positioned between the piston and cylinder wall and are crucial for maintaining pressure within the system. They allow for effective transfer of force while keeping the hydraulic fluid contained.

4. Backup Rings Often used in conjunction with O-rings or other seals, backup rings help prevent extrusion of seals under high pressure, thereby enhancing longevity and performance.

5. Wipers Located at the outer edge of the cylinder, wipers remove dust, dirt, and debris from the rod's surface, preventing contaminants from entering the hydraulic system and damaging seals.

Types of Seal Kits

Seal kits can vary based on application, material used, and compatibility with hydraulic fluids

. Some common types includeseal kit hydraulic

1. Standard Seal Kits These contain the most frequently used sizes and types of seals suitable for a wide range of hydraulic applications.

2. Custom Seal Kits Tailored to specific equipment or applications, custom kits ensure that all required components for a particular hydraulic system are included.

3. Multi-Pack Kits These are packages that include multiple seal sets suited for various machinery, ideal for businesses that operate a fleet of hydraulic equipment.

4. Material-Specific Kits With seal materials ranging from nitrile rubber to polyurethane, these kits cater to various temperature and chemical resistance requirements, allowing users to select based on their specific environment.

Importance of Seal Kits in Industries

In industries such as construction, agriculture, and manufacturing, hydraulic systems power critical machinery. Seal kits are integral to maintaining the performance and reliability of these systems. Their importance can be summarized in several key aspects

1. Preventing Fluid Leaks Effective seals help maintain the system's hydraulic pressure, preventing costly fluid leaks that can lead to environmental issues and increased operational costs.

2. Enhancing Equipment Longevity Regularly replacing seals as part of routine maintenance ensures that equipment functions optimally, reducing the likelihood of breakdowns and extending machinery life.

3. Improving Efficiency Systems equipped with properly functioning seals operate more efficiently, leading to reduced energy consumption and improved productivity.

4. Safety Seals are critical to the safe operation of hydraulic equipment. Leaks can pose safety hazards for workers and damage the equipment.

Conclusion

Understanding seal kits for hydraulic systems is fundamental for ensuring the reliability and efficiency of hydraulic machinery. By selecting the appropriate components and regularly maintaining these kits, industries can minimize downtime, enhance operational safety, and ensure the longevity of their hydraulic systems. As technology continues to progress, the development of innovative seal materials and designs will further refine the performance of hydraulic equipment, ultimately leading to advancements in productivity across various sectors. Whether you're in construction, manufacturing, or any other industry that relies on hydraulic systems, understanding and utilizing seal kits effectively is essential for optimal performance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories