Nov . 19, 2024 14:38 Back to list

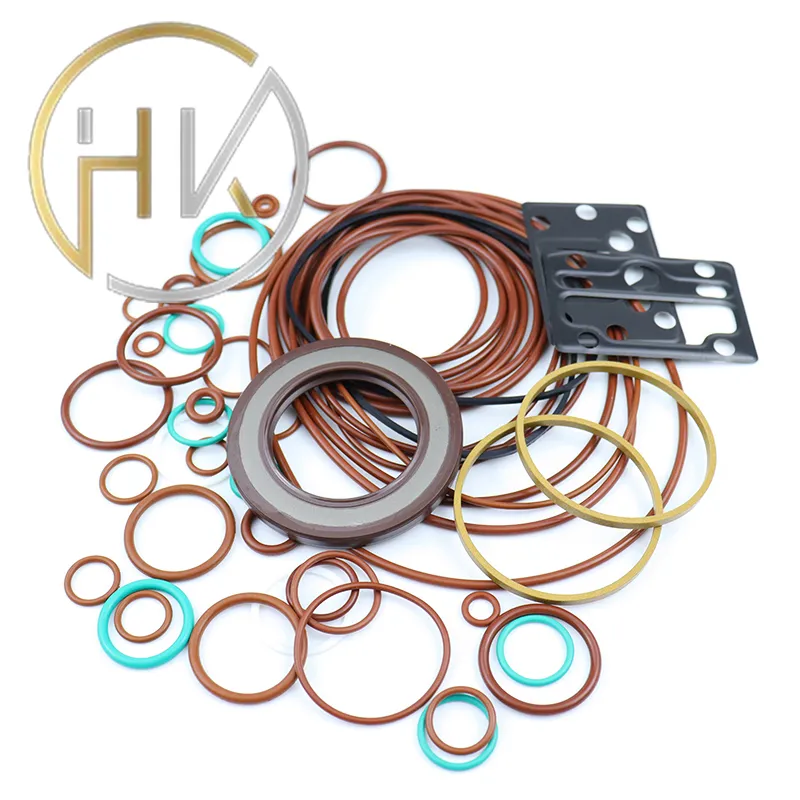

hydraulic seal repair kit

The Importance of Hydraulic Seal Repair Kits

Hydraulic systems are fundamental in numerous industrial and automotive applications, providing the power necessary for lifting, pushing, pulling, and moving various components. However, like any mechanical system, hydraulic systems can experience wear and tear over time, leading to leaks, inefficiencies, and potential failures. One of the most critical aspects of maintaining these systems is ensuring that seals function properly. This is where hydraulic seal repair kits come into play.

Understanding Hydraulic Seals

Hydraulic seals are devices that prevent the leakage of hydraulic fluids and other contaminants from entering or escaping the hydraulic system. They are crucial for maintaining pressure, ensuring system efficiency, and prolonging the lifespan of equipment. Common types of hydraulic seals include O-rings, rod seals, piston seals, and wipers. Each of these plays a unique role in maintaining the integrity of the hydraulic system.

The Role of Hydraulic Seal Repair Kits

A hydraulic seal repair kit typically includes a variety of seals, O-rings, and other essential components necessary for repairing or replacing worn-out seals in hydraulic systems. These kits are designed to provide a comprehensive solution for anyone looking to maintain or restore their hydraulic equipment, whether it be in construction machinery, automotive systems, or industrial equipment.

1. Cost-Effectiveness Investing in a hydraulic seal repair kit can save significant amounts of money in the long run. Instead of replacing an entire hydraulic component or system, users can simply replace the faulty seals, which is a much more affordable solution.

2. Ease of Use Many hydraulic seal repair kits are designed for ease of use, allowing individuals with basic mechanical skills to perform repairs without the need for specialized training or tools. This accessibility means that down-time for repairs can be minimized, enabling quicker return to service.

3. Variety of Components Most kits come with a range of seal types and sizes, catering to different applications. This versatility ensures that users have the right tool for the job at hand, allowing for a more comprehensive approach to hydraulic maintenance.

hydraulic seal repair kit

4. Quality Assurance Reputable manufacturers produce hydraulic seal repair kits using high-quality materials designed to withstand high pressure, temperatures, and exposure to various chemicals. This guarantees that repairs made using these kits will stand the test of time, keeping the hydraulic system functioning optimally.

Choosing the Right Kit

When selecting a hydraulic seal repair kit, it is essential to consider several factors

- Compatibility Always ensure that the seals in the kit are compatible with your specific hydraulic system. Check the manufacturer's specifications and match them with the seals provided in the kit.

- Quality Opt for kits made from durable materials that meet industry standards. Investing in high-quality seals can help avoid future leaks and extend the working life of your hydraulic equipment.

- Comprehensiveness Look for kits that offer a wide range of seals and components. The more options you have, the better equipped you will be to tackle any potential issues.

- Supplier Reputation Choose to buy from reputable suppliers or manufacturers with positive reviews and a history of customer satisfaction to ensure you receive a reliable product.

Conclusion

Hydraulic seal repair kits are invaluable tools for anyone involved in hydraulic maintenance, offering a cost-effective and efficient solution to common hydraulic issues. By understanding the importance of these kits and choosing the right one, operators can ensure their hydraulic systems operate smoothly, minimizing downtime and maximizing productivity. Regular inspection and maintenance with the help of these repair kits can significantly extend the life of hydraulic equipment, making them a cornerstone of effective hydraulic management.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories