Nov . 23, 2024 08:11 Back to list

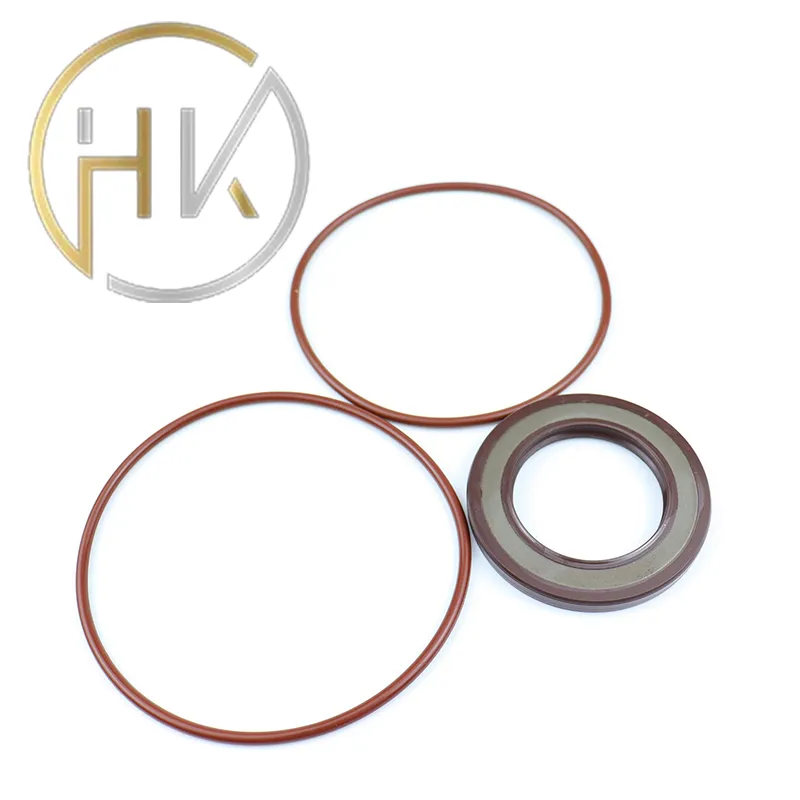

pump seal oil

Understanding Pump Seal Oil An Essential Component for Pump Longevity

When it comes to the reliable operation of industrial pumps, the importance of pump seal oil cannot be overstated. Pump seal oil serves as a crucial lubricating and sealing agent that helps to maintain the integrity and efficiency of pumps across various applications. Knowing how it works and its benefits can help enhance pump performance and longevity.

The primary function of pump seal oil is to create a barrier that prevents leaks from process fluids. This is particularly vital in industries where the movement of hazardous materials occurs, as ensuring safe operation is paramount. By providing a reliable seal, pump seal oil protects both the environment and personnel from potential risks associated with chemical exposure.

Additionally, pump seal oil acts as a lubricant for the mechanical components within the pump. Friction is an ever-present challenge in pumping systems, and excessive friction can lead to wear and tear on seals and other critical parts. By minimizing this friction, pump seal oil not only prolongs the life of seals but also enhances overall pump efficiency. A well-lubricated seal reduces heat generation, which can cause premature failure and costly downtime.

pump seal oil

Choosing the right type of pump seal oil is essential for optimal performance. There are various formulations available, each designed to suit different operating conditions and fluid types. For instance, some oils are formulated for high-temperature applications, while others may be better suited for chemically aggressive environments. It’s crucial to evaluate the specific requirements of the pump and its operating conditions when selecting an appropriate seal oil.

Regular maintenance and monitoring of pump seal oil levels are also vital practices. Over time, seal oil can degrade due to thermal and oxidative stresses. Establishing a routine schedule for checking oil levels, along with periodic oil changes, can contribute significantly to the reliability of pump systems. Being proactive in maintenance allows operators to catch issues before they escalate, substantially reducing the risk of pump failure.

In conclusion, pump seal oil is more than just a lubricant; it plays a pivotal role in ensuring the efficiency and safety of pumping systems. By creating effective seals and reducing friction, it helps maintain performance and prevent costly leaks. Selecting the right type of oil, coupled with diligent maintenance practices, will maximize pump longevity and reliability, ultimately saving time and resources in industrial operations. In an era where efficiency and safety are of utmost importance, understanding and utilizing pump seal oil effectively is a necessity for any operation reliant on pumping systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories