Nov . 23, 2024 08:26 Back to list

hydraulic pump seal kit

Understanding Hydraulic Pump Seal Kits Importance, Types, and Maintenance

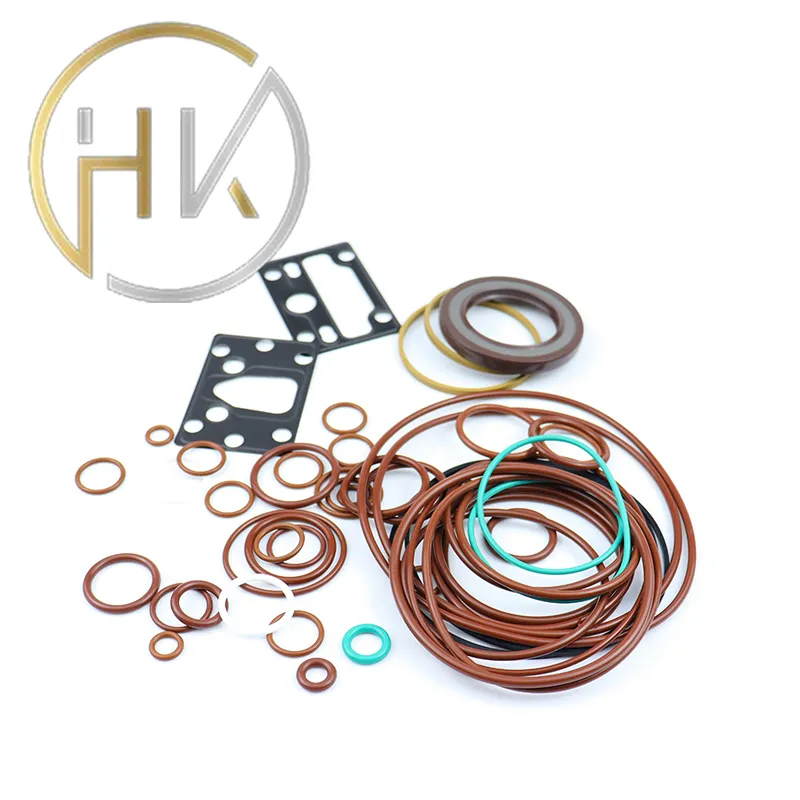

Hydraulic pump seal kits are critical components in the operation and longevity of hydraulic systems. These kits contain essential seals and gaskets designed to prevent fluid leaks, ensuring that hydraulic systems operate efficiently and effectively. This article explores the importance of hydraulic pump seal kits, the types available, and tips for maintenance to maximize the lifespan of your hydraulic systems.

Importance of Hydraulic Pump Seal Kits

Hydraulic pumps play a vital role in various industrial and machinery applications. They transfer hydraulic fluid through the system, generating power to move machinery and perform critical tasks. Without effective sealing, hydraulic fluids can leak, leading to a loss of efficiency, increased wear on pump components, and potential system failures.

Seal kits are necessary for the following reasons

1. Preventing Leaks The most critical function of seals is to prevent hydraulic fluid from leaking out of the pump. Leaks can lead to performance issues, loss of pressure, and increased operational costs.

2. Maintaining Pressure Proper seals help maintain the required hydraulic pressure in the system, ensuring that equipment operates smoothly and efficiently.

3. Protecting Components Seals not only prevent leaks but also protect internal components from contaminants, dirt, and moisture, which can cause serious damage over time.

4. Enhancing Efficiency By maintaining fluid integrity and pressure, seal kits contribute to the overall efficiency of the hydraulic system, translating to better performance and reduced energy consumption.

Types of Hydraulic Pump Seal Kits

Hydraulic pump seal kits come in various types, each designed for specific applications and pump models. Understanding these types can help you select the right kit for your needs

1. O-Rings Commonly used in hydraulic applications, O-rings provide a simple yet effective sealing solution. They are available in various sizes and materials, including nitrile and polyurethane, to match different fluids and temperature ranges.

2. U-Cups U-cup seals are designed for dynamic applications and are effective at sealing both static and dynamic power. They are often used in pistons and rods, providing excellent sealing performance under high pressures.

hydraulic pump seal kit

3. Lip Seals Also known as oil seals, lip seals are used to retain lubrication in rotating components. They are particularly effective in preventing the leakage of hydraulic fluids around rotating shafts.

4. Gaskets Gaskets provide sealing between flat surfaces, such as the junction of the pump housing and the cover. They are usually made from materials like rubber, cork, or silicone.

5. Backup Rings Sometimes used in conjunction with other seals, backup rings prevent extrusions and enhance the longevity of seals in high-pressure applications.

Maintenance Tips for Hydraulic Pump Seal Kits

Proper maintenance is key to ensuring the longevity and performance of hydraulic pump seal kits. Here are some essential tips for maintaining your hydraulic systems

1. Regular Inspections Routine checks for leaks, wear, and damage can help identify issues before they escalate. Pay close attention to the areas around seals and gaskets.

2. Fluid Quality Always use the recommended hydraulic fluid to prevent chemical reactions that can degrade seals. Regularly check and change fluids as necessary.

3. Operating Conditions Be aware of the operating environment. Extreme temperatures or contamination can lead to premature seal failure. Ensure that your hydraulic system operates within the recommended conditions.

4. Installation Ensure that seals are installed correctly, following manufacturer's guidelines. Incorrect installation can lead to leaks and reduce the lifespan of the seals.

5. Timely Replacement Be proactive in replacing seals when signs of wear are evident. Waiting until a leak occurs can lead to more significant issues and increased repair costs.

Conclusion

Hydraulic pump seal kits are essential for the reliable and efficient operation of hydraulic systems. Understanding their importance, the various types available, and how to maintain them properly can lead to improved performance and extended service life for your hydraulic machinery. By prioritizing seal maintenance and replacement, you can ensure that your hydraulic pumps operate at their best, minimizing downtime and maximizing productivity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories