Sep . 10, 2025 09:20 Back to list

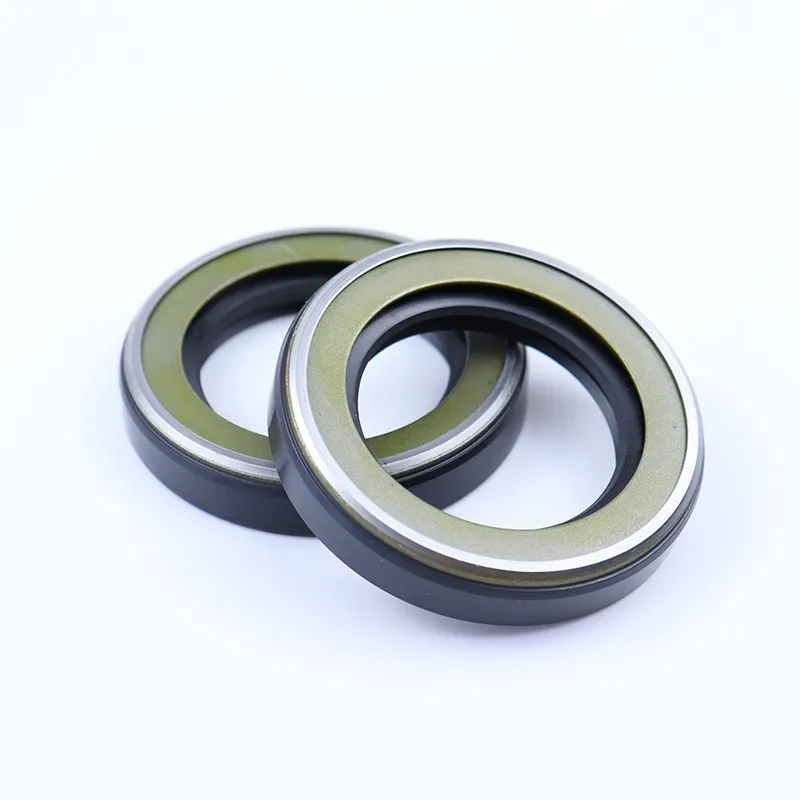

Pump Seal AP4212B TCN Oil Seal 110x140x14 | Durable & Reliable

Introduction to High-Performance Pump Sealing Solutions

In critical industrial applications, the reliability and efficiency of sealing components are paramount to operational integrity and longevity. Leaks can lead to significant downtime, environmental hazards, and increased maintenance costs. Addressing these challenges requires seals engineered for extreme conditions, precision, and durability. We present a detailed overview of the Pump seal AP4212B TCN oil seal 110-140--14, a cornerstone component designed to deliver exceptional performance in demanding pump environments.

This technical deep dive explores its advanced features, manufacturing precision, and versatile application potential, offering B2B decision-makers and engineers the comprehensive insights needed for informed procurement and integration.

Industry Trends in Fluid Sealing Technology

The global fluid sealing market is experiencing dynamic shifts driven by several key trends. There's an increasing demand for seals that offer enhanced chemical resistance, higher temperature tolerance, and superior abrasion resistance, particularly in sectors such as oil & gas, chemical processing, and power generation. Miniaturization and increased power density in industrial machinery also necessitate compact, high-performance sealing solutions capable of operating under increased pressure and speed. Furthermore, sustainability initiatives are driving the adoption of more durable, longer-lasting seals that reduce fugitive emissions and minimize the need for frequent replacements, aligning with environmental regulations and operational cost-saving objectives.

Advanced material science, including the development of specialized elastomers and fluoropolymers like NBR, FKM, and HNBR, continues to push the boundaries of seal performance. Digitalization and predictive maintenance are also influencing seal design, with integrated sensors becoming a nascent trend to monitor seal integrity and predict failure, thereby preventing costly unscheduled downtime. The Pump seal AP4212B TCN oil seal 110-140--14 is designed to meet these evolving demands, offering a robust solution that aligns with modern industrial requirements for efficiency and reliability.

Manufacturing Process Flow of the AP4212B TCN Oil Seal

The production of a high-performance oil seal like the Pump seal AP4212B TCN oil seal 110-140--14 involves a meticulously controlled, multi-stage process to ensure consistent quality and adherence to stringent technical specifications. Our commitment to precision engineering underpins every step.

Process Steps:

-

1

Material Selection & Preparation: Selection of high-grade NBR (Nitrile Butadiene Rubber) for its excellent resistance to petroleum-based oils and greases, coupled with good abrasion resistance. For more aggressive environments, FKM (Fluoroelastomer) or HNBR (Hydrogenated Nitrile Butadiene Rubber) options are available upon request for enhanced chemical and heat resistance. Raw materials undergo rigorous quality checks conforming to ASTM D2000 standards for polymer classification.

-

2

Metal Case Stamping/Forging: The robust outer metal case, providing structural integrity and interference fit, is typically manufactured from carbon steel (e.g., SAE 1010-1020) through precision stamping or cold forging. This process ensures dimensional accuracy and prevents deformation under operational stress.

-

3

Elastomer Molding (Compression/Injection): The prepared rubber compound is then molded onto the metal case. Compression molding or injection molding techniques are employed, depending on design complexity and volume, to create the precise lip profile and sealing element. Critical parameters like molding temperature, pressure, and cure time are strictly controlled to ensure optimal material properties and minimize flash.

-

4

Spring Insertion: For TCN (Double Lip with Spring) type seals, a garter spring made from high-tensile spring steel (e.g., SUS304 or carbon steel, depending on environment) is precisely inserted into the lip to maintain constant radial force against the shaft, ensuring a consistent seal over its operational life.

-

5

Trimming & Finishing: Excess material (flash) is removed, and seals undergo a final cleaning process.

-

6

Quality Control & Testing: Each batch undergoes rigorous testing to ISO 6194-1/2, DIN 3760, and ANSI B92.1 standards. This includes dimensional checks, material hardness (Shore A), tensile strength, elongation, compression set, and accelerated life testing under simulated operating conditions (e.g., high temperature, dynamic shaft rotation, pressure cycling). Leakage rates are meticulously monitored to ensure zero tolerance.

Target industries benefiting from this seal's robust design include petrochemical, metallurgy, mining, water supply & drainage, and general industrial pumping. Its design prioritizes advantages such as energy saving through minimized friction, superior corrosion resistance due to material selection, and extended service life up to 10,000 hours in typical application scenarios, significantly reducing total cost of ownership (TCO).

Technical Specifications and Parameters

The Pump seal AP4212B TCN oil seal 110-140--14 is engineered with precise dimensions and material properties to ensure optimal sealing performance. Its design focuses on robustness and adaptability to various operating conditions.

Product Specification Table: AP4212B TCN Oil Seal

| Parameter | Value/Specification |

|---|---|

| Product Name | AP4212B TCN Oil Seal |

| Shaft Diameter (d1) | 110 mm |

| Outer Diameter (d2) | 140 mm |

| Width (b) | 14 mm |

| Seal Type | TCN (Double Lip with Spring) |

| Sealing Lip Material | NBR (Nitrile Butadiene Rubber) - Standard; FKM/HNBR - Optional |

| Metal Case Material | Carbon Steel (SAE 1010-1020) |

| Garter Spring Material | Spring Steel (SUS304 or Carbon Steel) |

| Operating Temperature Range | -30°C to +100°C (NBR); -20°C to +200°C (FKM) |

| Max. Operating Pressure | Up to 0.03 MPa (0.3 bar) - Non-pressure applications; Consult for higher pressure. |

| Max. Shaft Speed | Up to 15 m/s (dependent on temperature and pressure) |

| Hardness of Sealing Lip | 70 ± 5 Shore A |

| Typical Service Life | > 8,000 hours (under optimal conditions) |

These specifications underscore the robust design of the AP4212B TCN seal, making it suitable for a broad spectrum of industrial applications where reliable sealing and resistance to environmental factors are critical. The TCN design, featuring a main sealing lip and an auxiliary dust lip, along with a garter spring, provides superior protection against both internal fluid leakage and external contaminant ingress, enhancing component lifespan.

Application Scenarios and Technical Advantages

The versatility of the Pump seal AP4212B TCN oil seal 110-140--14 allows its deployment across diverse and demanding industrial environments, leveraging its inherent technical advantages to optimize system performance and reliability.

Key Application Scenarios:

- Industrial Pumps: Widely used in centrifugal pumps, positive displacement pumps, and vacuum pumps found in chemical processing, wastewater treatment, and power generation, effectively sealing lubricating oils and hydraulic fluids.

- Gearboxes and Reducers: Critical for preventing lubricant leakage and protecting internal components from dust and moisture ingress in heavy-duty industrial gearboxes, ensuring smooth power transmission and extended service intervals.

- Agricultural Machinery: Employed in tractors, harvesters, and other farm equipment where exposure to dirt, mud, and harsh environmental conditions necessitates robust sealing.

- Construction Equipment: Integrated into excavators, loaders, and material handling systems to protect bearings and rotating shafts from abrasive particles and fluid contamination.

- Automotive and Heavy Vehicle Axles: Ensures reliable sealing in drive axles and wheel hubs, preventing oil loss and protecting against road contaminants.

Technical Advantages:

- Superior Sealing Integrity: The TCN profile, with its dual-lip design and garter spring, maintains a consistent radial force, providing effective static and dynamic sealing against both internal fluids and external particulate matter. This significantly reduces leakage rates and ingress of contaminants.

- Extended Service Life: Manufactured with high-grade NBR and precision-engineered metal cases, the seal exhibits excellent wear resistance and thermal stability. This translates into longer operational periods, reducing maintenance frequency and associated costs.

- Enhanced Chemical and Temperature Resistance: While NBR offers broad compatibility with common oils and fuels, customizable options with FKM or HNBR extend its resistance to aggressive chemicals and higher temperatures, expanding its application range in harsh environments.

- Reduced Friction and Energy Consumption: The optimized lip geometry and surface finish minimize friction during operation, leading to lower power loss in rotating equipment. This contributes to energy savings and improved overall system efficiency.

- Robust Construction: The integrated metal case provides structural rigidity and ensures a secure press fit into the housing bore, preventing rotation and maintaining seal stability even under vibrations or pressure fluctuations.

- Cost-Effectiveness: By reducing downtime, extending component life, and minimizing product loss due to leaks, the AP4212B TCN oil seal delivers a significant return on investment, contributing to a lower total cost of ownership.

Vendor Comparison and Competitive Edge

When selecting critical sealing components, a thorough vendor comparison is essential. While many manufacturers offer oil seals, the distinctions in material quality, manufacturing precision, and commitment to service can significantly impact long-term operational costs and system reliability. Our Pump seal AP4212B TCN oil seal 110-140--14 stands out due to a combination of superior design, robust manufacturing, and comprehensive support.

Comparative Analysis Table: AP4212B TCN vs. Generic Alternatives

| Feature | AP4212B TCN (Our Product) | Generic TCN Seal (Competitor A) | Economy NBR Seal (Competitor B) |

|---|---|---|---|

| Sealing Lip Material Quality | Premium Grade NBR (or FKM/HNBR option) with optimized compound formulation for wear and thermal stability. ISO 6194-1/2 compliance. | Standard Grade NBR, potentially with fillers compromising long-term resilience. Variable compliance. | Basic Grade NBR, lower compound integrity, susceptible to degradation. Minimal compliance. |

| Metal Case Material & Integrity | High-quality Carbon Steel, precision-stamped for consistent fit and corrosion resistance. Secure elastomer bonding. | Standard Carbon Steel, potentially less precise stamping, varying bonding strength. | Lower-grade steel, inconsistent stamping, prone to corrosion and bond failure. |

| Garter Spring Quality | High-tensile Spring Steel (SUS304/Carbon), consistent force, corrosion resistant. | Standard Spring Steel, variable tension, susceptible to fatigue over time. | Basic steel wire, prone to corrosion and loss of tension, leading to early failure. |

| Operating Temperature Range (NBR) | -30°C to +100°C (Guaranteed) | -20°C to +90°C (Typical) | -10°C to +80°C (Limited) |

| Typical Service Life | > 8,000 hours (Proven by lab/field tests) | 3,000 - 5,000 hours (Variable) | < 2,000 hours (Frequent replacement needed) |

| Quality Certifications | ISO 9001:2015, ISO 14001, Material Test Reports (MTRs) for each batch. | Basic ISO 9001, limited specific product certifications. | Often uncertified or self-declared. |

| After-Sales Support & Warranty | Comprehensive technical support, 1-year product warranty, application engineering. | Limited support, standard short warranty period. | Minimal or no dedicated support. |

This comparison highlights the significant long-term value offered by the AP4212B TCN oil seal. Investing in a higher-quality seal prevents costly equipment failures, reduces maintenance expenditures, and ensures consistent operational uptime, directly impacting profitability. Our commitment to stringent manufacturing processes and material traceability ensures that every Pump seal AP4212B TCN oil seal 110-140--14 delivers on its promise of reliability and performance.

Customized Solutions and Application Case Studies

Recognizing that standard solutions may not always address unique operational challenges, we offer customized versions of the AP4212B TCN oil seal. Our engineering team collaborates closely with clients to tailor material compounds, lip geometries, and metal casing designs to meet specific pressure, temperature, chemical compatibility, or speed requirements. This bespoke approach ensures optimal sealing performance even in the most unconventional applications.

Customization Capabilities:

- Material Upgrades: Options for FKM, HNBR, or Silicone for enhanced chemical, high-temperature, or low-temperature resistance.

- Corrosion-Resistant Metal Cases: Stainless steel (e.g., SUS304, SUS316) options for highly corrosive environments.

- Surface Treatments: Application-specific coatings or treatments for the metal case or elastomer surface to improve friction characteristics or chemical resistance.

Application Case Studies:

Case Study 1: Enhanced Reliability in Chemical Processing

Client: Major Petrochemical Plant, Gulf Coast Region

Challenge: A critical pump handling highly corrosive chemical reagents at elevated temperatures (150°C) experienced frequent oil seal failures (every 3-4 months) using standard NBR seals. This resulted in significant production downtime and high maintenance costs.

Solution: We provided a customized Pump seal AP4212B TCN oil seal 110-140--14 variant, featuring an FKM sealing lip for superior chemical and heat resistance, combined with a SUS316 stainless steel garter spring. The modified seal underwent extensive pre-application testing to simulate the exact operating conditions.

Results: The customized seals extended the Mean Time Between Failures (MTBF) from 3-4 months to over 18 months, representing a more than 450% improvement in seal life. This led to an estimated annual saving of $150,000 in maintenance and lost production costs, alongside enhanced safety and environmental compliance.

Case Study 2: Preventing Contamination in Mining Equipment

Client: Large-scale Open-Pit Mining Operation, Western Australia

Challenge: Heavy-duty conveyor system gearboxes operating in dusty, abrasive conditions experienced premature bearing failures due to particulate ingress through standard oil seals, despite frequent shaft cleaning. Seal life averaged 6 months.

Solution: We implemented the standard Pump seal AP4212B TCN oil seal 110-140--14, leveraging its robust NBR compound and the integral auxiliary dust lip (TCN profile). The dual-lip design was specifically chosen for its enhanced ability to block external contaminants while retaining internal lubricants.

Results: The deployment of the AP4212B TCN seal reduced bearing contamination significantly. Subsequent inspections showed markedly cleaner lubricant and minimal wear on bearings. Seal lifespan increased to over 12 months, effectively doubling the service interval and reducing gearbox overhaul frequency by 50%. This directly translated into reduced operational expenditures and increased equipment availability.

Ensuring Trust and Reliability: Company Commitments

Frequently Asked Questions (FAQ)

A1: Standard stock items typically ship within 3-5 business days. For customized orders, lead times range from 2-4 weeks, depending on complexity and material availability. Expedited options are available upon request.

A2: The AP4212B TCN is designed for minimal maintenance. Regular inspection of the shaft and housing for concentricity, surface finish, and proper lubrication is recommended. No periodic adjustments are typically required for the seal itself, though shaft wear should be monitored.

A3: Correct installation is crucial. We provide detailed installation guidelines and best practices. Key steps include ensuring the shaft and housing bores are clean and free of burrs, using a proper installation tool to prevent lip damage, and applying a thin film of lubricant to the sealing lips prior to insertion. Misalignment or excessive force during installation can significantly reduce seal life.

A4: Seals should be stored in a cool, dry place away from direct sunlight, UV radiation, and ozone-generating equipment (e.g., electric motors). Storage temperatures should ideally be between 15°C and 25°C. Avoid stacking heavy objects on seals to prevent deformation.

Lead Time & Fulfillment

Our robust supply chain and optimized manufacturing processes enable efficient order fulfillment. Standard Pump seal AP4212B TCN oil seal 110-140--14 configurations are typically in stock for immediate dispatch or have very short lead times. For custom specifications or high-volume orders, we provide transparent production schedules and reliable delivery forecasts, ensuring your project timelines are met. Global shipping options are available to cater to international clients.

Warranty Commitments

We stand behind the quality and performance of our products. The AP4212B TCN oil seal comes with a standard 12-month warranty against manufacturing defects from the date of purchase. This commitment reflects our confidence in our stringent quality control and superior engineering. Specific warranty terms for customized solutions will be outlined in the project agreement.

Dedicated Customer Support

Our commitment to our clients extends beyond product delivery. We offer comprehensive pre-sales consultation and post-sales technical support. Our team of experienced engineers and application specialists is available to assist with product selection, installation guidance, troubleshooting, and optimization strategies to ensure the maximum lifespan and effectiveness of your Pump seal AP4212B TCN oil seal 110-140--14. We aim to be a long-term partner in your operational success.

Citations

- ISO 6194-1: Rotary shaft lip type seals — Dimensions and tolerances of single lip seals. International Organization for Standardization.

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications. ASTM International.

- DIN 3760: Rotary shaft lip type seals — Dimensions. Deutsches Institut für Normung.

- Norton, R. L. (2019). Machine Design: An Integrated Approach. Pearson Education.

- Bhushan, B. (2013). Introduction to Tribology. John Wiley & Sons.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories