Dec . 05, 2024 14:10 Back to list

oil seal supplier

Choosing the Right Oil Seal Supplier A Comprehensive Guide

In various industries such as automotive, manufacturing, and machinery, oil seals play a crucial role in ensuring the longevity and efficiency of equipment. An oil seal, also known as a rotary shaft seal, is designed to prevent the leakage of lubricants while safeguarding against contaminants. Selecting the right oil seal supplier can significantly influence your operations, product reliability, and overall project success. Here’s a comprehensive guide on how to choose an effective oil seal supplier.

Understanding Oil Seals

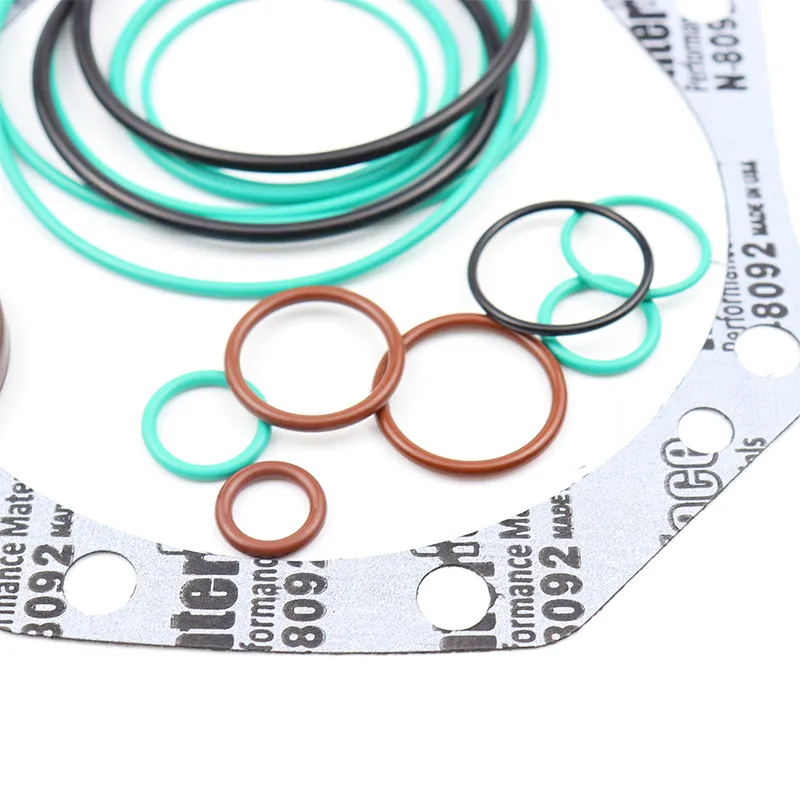

Before diving into supplier selection, it’s essential to understand what oil seals are and their importance. Depending on the design and application, oil seals come in various types, including lip seals, O-rings, and V-rings. Each type serves a specific purpose and is made from different materials such as rubber, silicone, and PTFE (Teflon). The right oil seal can help reduce friction and wear in rotating shafts, thereby enhancing the lifespan of machinery.

Key Factors to Consider When Choosing an Oil Seal Supplier

1. Quality Assurance Quality should be your top priority when selecting an oil seal supplier. Check if the supplier adheres to industry standards and possesses relevant certifications, such as ISO 9001. A reputable supplier will provide high-quality products that undergo rigorous testing to ensure durability and performance.

2. Range of Products It is beneficial to choose a supplier that offers a diverse range of oil seals to cater to various applications. Whether you need standard sizes or custom designs, a supplier with a broad inventory can meet your specific requirements and reduce the time spent searching for multiple vendors.

3. Expertise and Experience The supplier's expertise and experience in the field can significantly impact your project. Look for suppliers that have been in business for several years and have a deep understanding of oil seal applications across different industries. Their experience will often translate to better advisory services and customized solutions.

oil seal supplier

4. Customization Options Your industrial needs may sometimes require custom-designed seals. A good oil seal supplier should offer customization services to provide seals tailored to specific dimensions, materials, and applications. This flexibility can enhance performance and compatibility with your equipment.

5. Customer Service Assess the level of customer service provided by the supplier. Good communication and support can make a substantial difference in resolving issues, answering queries, and ensuring timely deliveries. Look for suppliers who are responsive and willing to provide guidance throughout the purchasing process.

6. Pricing and Value While the price is an important factor, it should not be the sole deciding element. Evaluate the value offered by the supplier in terms of quality, reliability, and customer support. Sometimes paying a bit more for a high-quality product can save costs in maintenance and replacements in the long run.

7. Delivery and Logistics Consider the supplier's ability to deliver products on time. Delays in receiving oil seals can halt production and lead to significant financial losses. Suppliers with efficient logistics and inventory management systems can ensure timely delivery and minimize downtime.

8. Reputation and Reviews Research the reputation of the supplier in the industry. Customer reviews, testimonials, and case studies can provide insights into the reliability and quality of their products. A supplier with a strong positive reputation is more likely to meet your expectations.

Conclusion

Choosing the right oil seal supplier is a critical decision that can impact your operational efficiency and equipment reliability. By considering factors such as quality, product range, expertise, customization options, customer service, pricing, delivery, and reputation, you can make a well-informed choice. Investing time in finding a reputable oil seal supplier will not only enhance the performance of your equipment but also contribute to the long-term success of your business.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories