Dec . 05, 2024 14:10 Back to list

Understanding Seals for Hydraulic Motors and Their Importance in System Performance

Understanding Hydraulic Motor Seals Their Importance and Functionality

Hydraulic motors play a crucial role in various industrial applications, converting hydraulic energy into mechanical energy to drive a variety of machinery. One critical component that ensures the efficiency and reliability of hydraulic motors are the seals. Hydraulic motor seals are designed to prevent fluid leakage, maintain pressure, and protect against contaminants. In this article, we will explore the types, functions, and importance of hydraulic motor seals in ensuring optimal performance.

Types of Hydraulic Motor Seals

There are several types of seals used in hydraulic motors, each serving a specific purpose

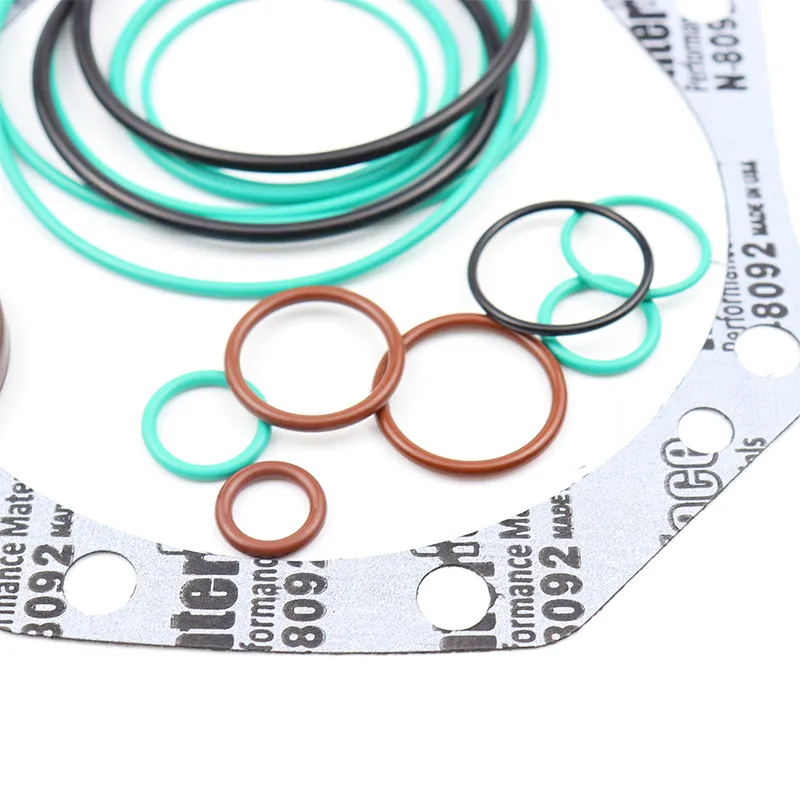

1. Shaft Seals These are used to seal the rotating shaft of the motor, preventing hydraulic fluid from leaking out and contaminants from entering. Common materials for shaft seals include nitrile rubber, fluorocarbon, and polyurethane, each providing different levels of resistance to fluids and temperatures.

2. O-Rings O-rings are circular seals made of rubber or other elastomers that create a tight seal between two surfaces. They are commonly used in hydraulic motors to seal joints and prevent leaks, especially in static applications.

3. Backup Rings Often used in conjunction with O-rings, backup rings provide additional support to prevent the O-ring from extruding and losing its effectiveness. They are crucial in high-pressure applications where the risk of seal failure is greater.

4. Wiper Seals These seals are designed to remove dirt and debris from the shaft as it rotates, preventing contamination of the hydraulic fluid. Wiper seals ensure that the internal components of the hydraulic motor remain clean and functional.

5. Piston Seals These seals are used in hydraulic cylinders and motors, ensuring that hydraulic fluid does not leak past the piston during operation. Effective piston seals are critical for maintaining the efficiency of the hydraulic system.

Functions of Hydraulic Motor Seals

The primary functions of hydraulic motor seals include

hydraulic motor seals

- Leak Prevention One of the most important roles of seals is to prevent hydraulic fluid from escaping the system. Leakages can lead to decreased efficiency and increased operational costs.

- Pressure Maintenance Seals help maintain the pressure within the hydraulic system, which is essential for the proper functioning of the motor. Inadequate pressure can lead to lost power and reduced performance.

- Contaminant Protection Hydraulic systems are susceptible to contamination from dirt, dust, and other particles. Seals act as barriers, protecting the internal components of the motor and prolonging its life.

- Temperature Control Seals must withstand a range of temperatures. High-quality seals can maintain their integrity under extreme thermal conditions, ensuring consistent performance.

Importance of Regular Inspection and Maintenance

While hydraulic motor seals are designed for durability, they are not impervious to wear and tear. Regular inspection and maintenance are essential to ensure their longevity and effective performance. Signs of failing seals may include fluid leaks, increased operational noise, or fluctuating pressure levels.

Routine maintenance may involve

- Checking for visible signs of wear or damage - Replacing worn-out seals before they lead to major failures - Monitoring fluid levels and quality to prevent contamination

Identifying issues early helps avoid expensive repairs and prolongs the life of the hydraulic motor.

Conclusion

Hydraulic motor seals are integral to the efficiency and reliability of hydraulic systems. By understanding the types and functions of these seals, industries can ensure that their machinery operates smoothly and effectively. Regular maintenance and timely replacement of seals not only enhance performance but also significantly reduce the risk of equipment failure, leading to increased productivity and cost savings. Investing in quality hydraulic seals and maintenance practices is a step toward a robust and efficient hydraulic system.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories