Nov . 29, 2024 12:21 Back to list

Top Quality Oil Seal Suppliers for Reliable Performance and Durability

Understanding Oil Seal Manufacturers Key Players in the Automotive and Industrial Industries

Oil seals are essential components in a variety of machinery, including automotive engines and industrial equipment. Their primary function is to prevent the leakage of lubricating oil while also keeping contaminants out, thereby enhancing the performance and longevity of the machinery. The effectiveness and reliability of oil seals depend significantly on the manufacturers who produce them. In this article, we will explore the role of oil seal manufacturers and the factors that influence their operations.

The Importance of Oil Seals

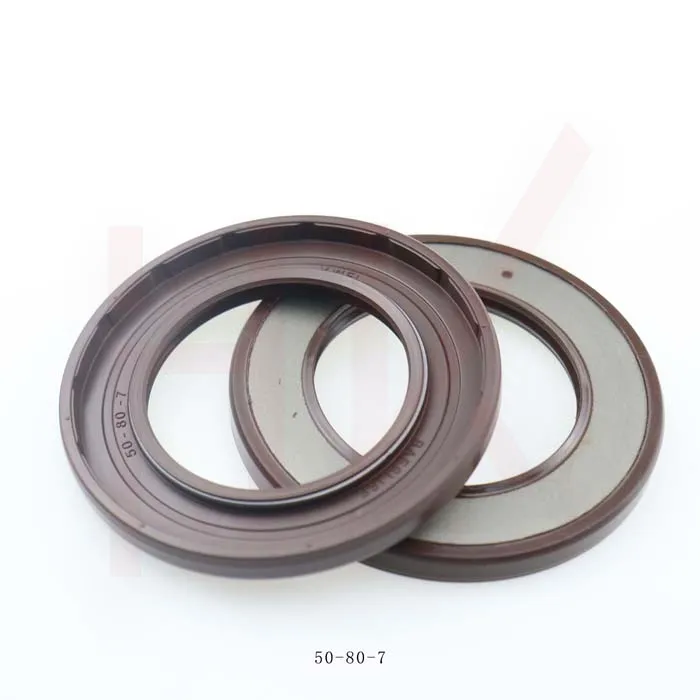

Oil seals, also known as shaft seals or fluid seals, are designed to fit snugly around rotating shafts, ensuring that lubricant remains contained within the machinery. They are critical for the proper functioning of engines, pumps, and other equipment where lubrication is essential for reducing friction and heat. Without effective oil seals, machinery can suffer from oil leaks, which can lead to severe damage, increased maintenance costs, and reduced operational efficiency.

Key Players in the Industry

The market for oil seals is diverse, featuring numerous manufacturers worldwide. These companies may operate on a global scale or focus on regional markets. Major players often invest heavily in research and development to innovate and improve the quality of their products. This includes the use of advanced materials and manufacturing techniques to create seals that can withstand extreme temperatures, pressures, and chemical exposure.

Selection Criteria for Manufacturers

When choosing an oil seal manufacturer, several critical criteria come into play

. These include1. Quality Assurance A reputable manufacturer should adhere to stringent quality control measures. This includes certifications such as ISO 9001, which indicates a commitment to maintaining high-quality standards throughout the manufacturing process.

oil seal manufacturer

2. Material Selection The choice of materials is vital for the functionality of oil seals. Manufacturers often use nitrile rubber, fluorocarbon, silicone, and other specialized materials capable of resisting wear and chemical exposure. A good manufacturer will offer a variety of materials to suit different applications.

3. Customization Capabilities Different applications require specific dimensions and characteristics for oil seals. Manufacturers that offer customization can provide tailored solutions to meet unique engineering specifications.

4. Research and Development Continuous investment in R&D is crucial for manufacturers to stay ahead in a competitive market. Companies that focus on innovation can develop advanced sealing technologies that enhance performance and reliability.

5. Customer Support and Service A responsive customer service team is essential for addressing inquiries, providing technical support, and ensuring smooth order fulfillment. Manufacturers that prioritize customer engagement often foster long-term partnerships with their clients.

The Future of Oil Seal Manufacturing

As industries increasingly focus on sustainability and efficiency, oil seal manufacturers must adapt to new challenges. The push for electric vehicles and green technologies is shaping the future of oil seal design and materials. Manufacturers are exploring eco-friendly materials and production processes to align with global sustainability goals.

Furthermore, advancements in manufacturing technology, such as automation and additive manufacturing (3D printing), are expected to revolutionize the industry, allowing for faster production times and reduced costs.

Conclusion

Oil seal manufacturers play a crucial role in ensuring the reliability and efficiency of a variety of machines. By prioritizing quality, innovation, and customer satisfaction, these manufacturers contribute significantly to the automotive and industrial sectors. As the industry evolves, the continuous pursuit of excellence and sustainability will remain pivotal in shaping the future of oil seals and their manufacturers. Whether for automotive applications or industrial machinery, choosing the right oil seal manufacturer can make a significant difference in operational performance and machine longevity.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories