Feb . 13, 2025 11:17 Back to list

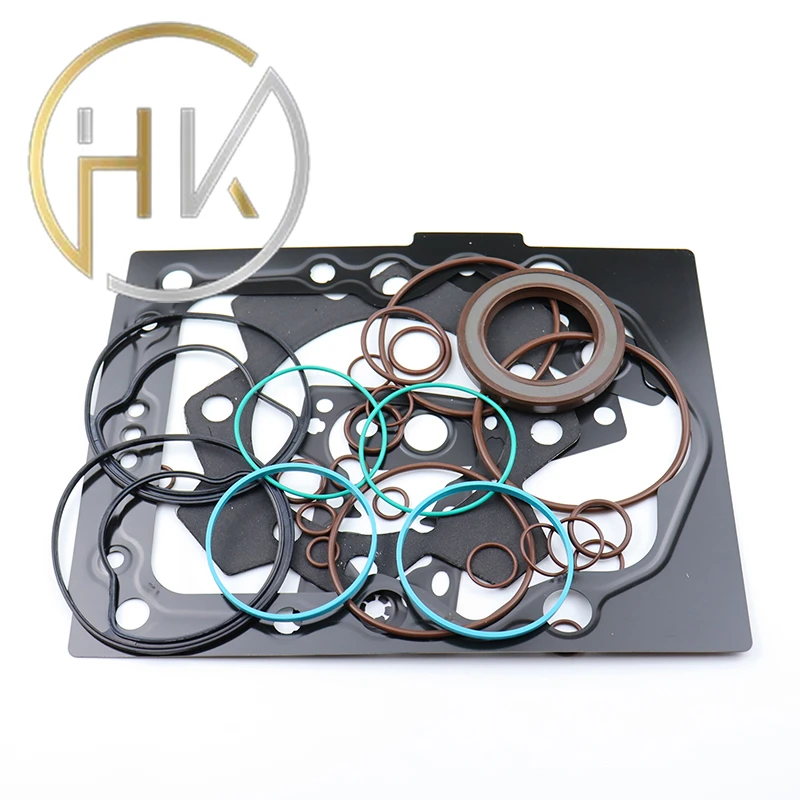

metric shaft seals

From a technical perspective, precision in the manufacturing process of metric shaft seals is non-negotiable. High-quality seals are machined to exacting standards, ensuring they fit perfectly into mechanical systems to prevent any slippage or misalignment that could lead to system failures. This precision manufacturing process reflects the expertise and authoritative knowledge invested in producing these components, underpinning their reliability and efficiency. Trustworthiness is further reinforced by seals that comply with international standards and certifications. Products that meet or exceed these standards assure users of their quality and performance, providing peace of mind that they can withstand the rigors of their specific application environments. Companies that focus on compliance not only demonstrate their commitment to quality but also their responsibility towards sustainable practices and user safety. Incorporating feedback loops into product development is another facet of building trust and authority in this field. By continuously engaging with customers and field operators to gather data and insights, manufacturers can refine their designs and materials, ensuring their metric shaft seals evolve to meet emerging challenges and technical requirements. This adaptive approach exemplifies the experience, expertise, and commitment manufacturers have in delivering top-tier solutions. In summary, metric shaft seals are indispensable components that drive efficiency and reliability across various industries. By leveraging advanced materials, precision engineering, and strict adherence to international standards, manufacturers are not only enhancing the performance of these seals but also building a reputation grounded in expertise and trust. Whether it's for new installations or replacing existing seals, opting for high-quality, application-specific metric shaft seals is a decision that promises long-term rewards in performance and cost savings.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories