Sep . 01, 2024 21:46 Back to list

Metal Cased Oil Seals - High Performance and Durability

The Importance of Metal Cased Oil Seals in Machinery

Oil seals, also known as shaft seals, play a crucial role in various mechanical systems by preventing lubricants from leaking while keeping contaminants such as dirt, dust, and moisture at bay. Among the different types of oil seals available, metal cased oil seals are particularly valued for their durability and performance in challenging environments. This article explores the significance of metal cased oil seals in machinery and their applications.

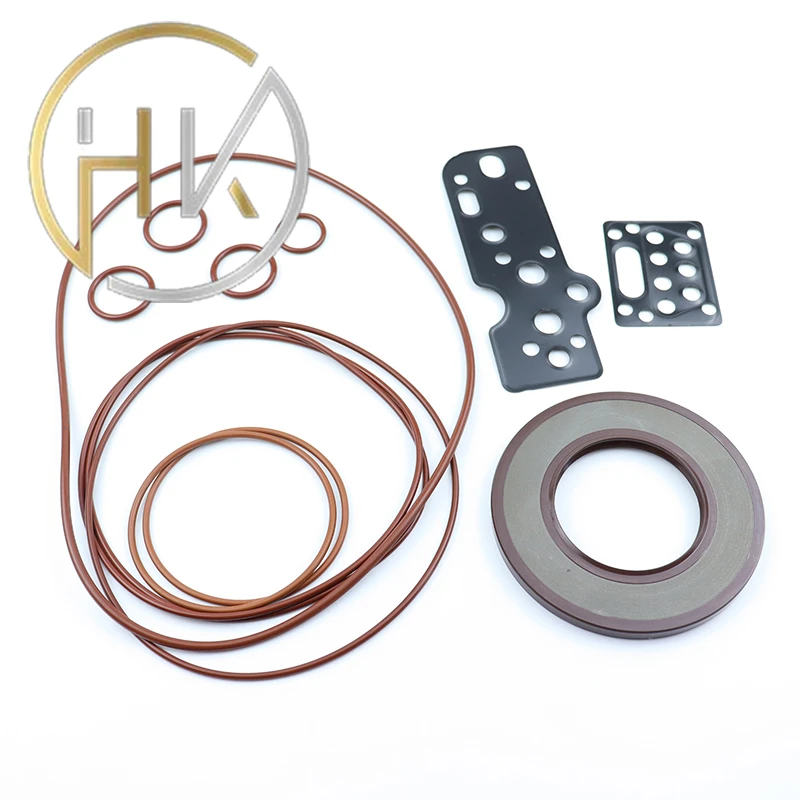

Metal cased oil seals are designed with a robust metal outer casing that provides enhanced stability and structural integrity. This construction features a resilient elastomeric lip that establishes a tight seal around the shaft. The metal casing plays a pivotal role in reinforcing the seal against external pressures, making it ideal for high-speed and heavy-duty applications. These seals are commonly utilized in automotive engines, industrial machinery, gearboxes, and hydraulic systems.

One of the main advantages of metal cased oil seals is their ability to withstand extreme temperatures and harsh operating conditions. The metal casing protects the elastomeric material from being degraded by heat or aggressive chemicals, thereby prolonging the seal's lifespan. This attribute makes them suitable for environments where other types of seals might falter, leading to costly downtimes and repairs.

metal cased oil seals

Furthermore, metal cased oil seals are designed to accommodate fluctuations in pressure, ensuring leak-proof operation

. In applications involving rotating shafts, the seal must maintain its effectiveness despite the wear and tear that comes from continuous motion. The sturdy metal casing helps to prevent distortion, ensuring that the seal maintains a consistent contact with the shaft surface.In addition to their mechanical resilience, metal cased oil seals are available in various sizes and designs to cater to a multitude of applications. Manufacturers offer a wide range of customization options, including different lip designs and materials, enabling engineers to select the most suitable seal for their specific needs. This versatility ensures that machinery can operate efficiently across diverse industries, from automotive to aerospace and beyond.

Moreover, the performance of metal cased oil seals is enhanced by their installation process. Correct installation is vital to ensure that the seals provide optimal performance and prevent premature failure. Engineers must pay attention to surface finishes and alignment when fitting these seals, as any imperfections can lead to leaks or increased wear.

In conclusion, metal cased oil seals are indispensable components in modern machinery. Their robust construction, ability to withstand extreme conditions, and versatility in applications make them a preferred choice in many industries. By investing in quality metal cased oil seals, businesses can enhance the longevity and efficiency of their equipment, ultimately leading to reduced maintenance costs and improved operational reliability.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories