Aug . 18, 2025 01:40 Back to list

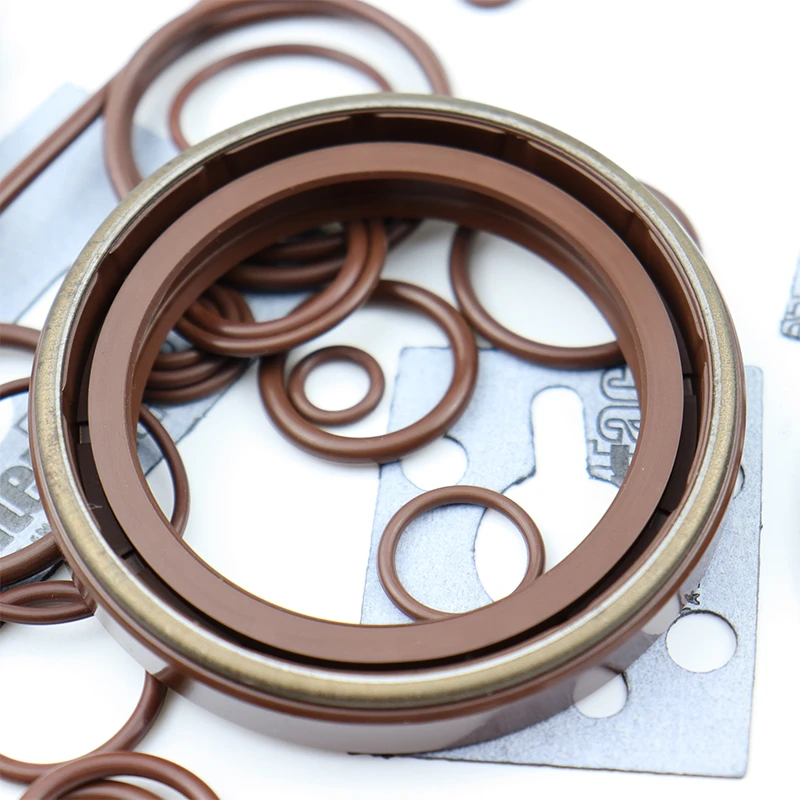

Hydraulic Pump Repair Kit 776872 51V250 Up0803e Seal Kit

Navigating the Imperative of Hydraulic System Longevity and Efficiency

In the demanding landscape of modern industrial operations, the reliability and efficiency of hydraulic systems stand as cornerstones of productivity and operational continuity. From heavy construction machinery and intricate manufacturing robotics to vast offshore oil rigs and critical aerospace applications, hydraulic pumps are the pulsating heart, converting mechanical energy into hydraulic power. The integrity of these systems hinges significantly on the quality of their sealing components, which directly impact fluid containment, system pressure, and overall performance. Industry trends consistently highlight a surging demand for high-performance, durable, and cost-effective maintenance solutions that minimize downtime and extend the operational lifespan of vital equipment. This paradigm shift underscores the critical importance of selecting superior repair components. Our specialized Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit emerges as an indispensable asset in this context, precisely engineered to meet the rigorous demands of continuous industrial use. It addresses the pervasive challenges of wear, chemical degradation, and thermal stress that compromise hydraulic pump seals over time. By providing a comprehensive, precision-engineered solution, this kit not only restores peak performance but also significantly enhances the resilience of hydraulic systems against future operational adversities, ensuring that complex machinery operates at optimal efficiency and reliability. The market's increasing focus on predictive maintenance and proactive component replacement strategies further solidifies the essential role of such specialized kits in modern industrial ecosystems.

The drive for increased operational uptime and reduced maintenance expenditures necessitates a forward-thinking approach to component procurement and application. With operational costs continually under scrutiny, the ability to restore existing equipment to "like-new" performance specifications, rather than resorting to costly full replacements, offers substantial economic advantages. This strategy is particularly pertinent for hydraulic pumps, where internal sealing elements are subjected to extreme pressure differentials, high-frequency cycling, and exposure to various hydraulic fluids, often at elevated temperatures. The degradation of these seals can lead to internal and external leakage, cavitation, reduced volumetric efficiency, and ultimately, catastrophic system failure. The advent of advanced material science and precision manufacturing techniques has paved the way for repair kits that not only match but often exceed the performance characteristics of original equipment seals. Our commitment to incorporating cutting-edge materials and stringent quality control ensures that each component within the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit contributes to a robust, long-lasting repair solution. This commitment aligns seamlessly with the prevailing industry trend towards sustainable maintenance practices, minimizing waste and maximizing the utility of existing capital assets, thereby providing significant value for B2B stakeholders who prioritize both performance and environmental responsibility in their operational strategies.

Precision Engineering: Unpacking the Technical Specifications of the Seal Kit

The efficacy of any hydraulic component lies in its detailed technical specifications and the judicious selection of materials. The Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit is meticulously engineered with a combination of advanced elastomers and thermoplastics, each chosen for its specific properties that contribute to superior sealing performance under arduous conditions. Key materials often include Nitrile Butadiene Rubber (NBR) for general-purpose applications due to its excellent resistance to petroleum-based oils and greases, and Fluorocarbon Rubber (FKM/Viton) for high-temperature and aggressive chemical environments. Additionally, Polytetrafluoroethylene (PTFE) may be utilized for backing rings or piston seals, offering exceptionally low friction and high chemical resistance, crucial for dynamic sealing applications where wear reduction is paramount. These materials are selected not only for their inherent mechanical strength and elasticity but also for their compatibility with a wide range of hydraulic fluids, including mineral oils, water glycols, and synthetic esters, ensuring broad applicability across diverse hydraulic systems. The design of each seal within the kit, whether it be an O-ring, U-cup, rod seal, or piston seal, adheres to precise dimensional tolerances, critical for achieving an optimal interference fit and preventing fluid bypass. Our rigorous quality control processes ensure that every component in the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit meets or exceeds the original equipment manufacturer (OEM) specifications, providing peace of mind for engineers and maintenance professionals.

| Parameter | Specification | Description/Benefit |

|---|---|---|

| Main Seal Material | High-Grade FKM (Viton) / NBR Compounds | Superior chemical resistance, wide temperature range (-20°C to +200°C), excellent compression set for long-term sealing. |

| Backing Ring Material | Engineered PTFE (Polytetrafluoroethylene) | Reduces friction, prevents extrusion of primary seals under high pressure, enhances wear resistance. |

| Operating Pressure Range | Up to 450 bar (6500 psi) dynamic; 600 bar (8700 psi) static | Ensures robust sealing integrity in high-pressure hydraulic systems, minimizing leakage and maintaining efficiency. |

| Operating Temperature Range | -30°C to +120°C (NBR), -20°C to +200°C (FKM) | Adaptability to extreme thermal conditions prevalent in industrial applications, preventing seal degradation. |

| Fluid Compatibility | Mineral oils (HL, HLP), Water-glycol (HFC), Phosphate esters (HFD-R/S) | Versatile application across various hydraulic fluid types, preventing material swelling or chemical attack. |

| Service Life Expectancy | Up to 10,000 hours (under optimal conditions) | Extended operational lifespan of the pump after repair, reducing frequency of maintenance and associated costs. |

Beyond material composition, the geometry and surface finish of each seal component are critical. Precision grinding and polishing techniques ensure that sealing surfaces are smooth and free of imperfections that could lead to premature wear or leakage. Specialized manufacturing processes like high-pressure molding and vulcanization for elastomers ensure uniform material density and optimal cross-linking, which are vital for maintaining elasticity and resistance to permanent deformation. For components like backing rings, advanced CNC machining ensures exact dimensional accuracy and tight tolerances, preventing extrusion gaps and enhancing the overall sealing integrity. The comprehensive nature of the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit, encompassing all necessary static and dynamic seals, wipers, and O-rings, simplifies the repair process and guarantees a holistic solution. This holistic approach significantly reduces the risk of component incompatibility or overlooking a critical sealing element, which could otherwise compromise the entire repair effort. Such meticulous attention to detail in material selection, design, and manufacturing positions this kit as a leading solution for hydraulic pump maintenance, designed to extend the mean time between failures (MTBF) and ensure reliable, leak-free operation for diverse industrial applications demanding robust hydraulic performance.

The Advanced Manufacturing Process Behind Each Seal Kit

The superior performance of the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit is rooted in an advanced manufacturing process that emphasizes precision, material integrity, and rigorous quality control at every stage. The journey begins with the meticulous sourcing of raw materials, such as high-grade FKM, NBR, and PTFE, from certified suppliers who adhere to stringent international standards. Upon arrival, these materials undergo comprehensive incoming quality inspection (IQI), including spectroscopic analysis, hardness testing (Shore A, D), and tensile strength evaluation, to ensure they meet exact specifications and chemical purity requirements. Once approved, the materials proceed to the compounding phase, where proprietary blends are created to optimize properties such as elasticity, chemical resistance, and thermal stability. For elastomer components, this involves precise mixing and calendering to prepare the material for molding. The next critical step is molding and vulcanization, where specialized compression or injection molding techniques are employed to form the seals under controlled temperature and pressure, ensuring optimal cross-linking and dimensional accuracy.

For hard plastic components like PTFE backing rings, state-of-the-art CNC machining is utilized. This ensures micron-level precision for critical dimensions, guaranteeing a perfect fit within the pump's sealing grooves. Automated optical inspection systems are integrated into the production line to detect even the slightest defects, such as burrs, surface imperfections, or dimensional deviations, ensuring that only flawless components proceed to the next stage. Post-molding or machining, seals undergo a series of comprehensive tests:

- Pressure Testing: Seals are subjected to various pressure cycles to simulate operational conditions, verifying their resistance to extrusion and maintaining seal integrity.

- Temperature Cycling: Components are tested across their specified operating temperature range to assess their performance under thermal fluctuations, ensuring no degradation in sealing capability.

- Fluid Compatibility Tests: Samples are immersed in various hydraulic fluids to confirm resistance to swelling, degradation, or changes in mechanical properties, adhering to industry standards like ISO 1817.

- Accelerated Life Testing: To predict service life, seals undergo accelerated wear tests, providing robust data on their durability and longevity, aiming for a service life of up to 10,000 operational hours under ideal conditions.

Optimizing Performance: Application Scenarios and Distinct Advantages

The versatility and robust design of the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit render it indispensable across a multitude of heavy-duty industrial sectors where hydraulic power is paramount. In the construction and mining industries, where equipment like excavators, loaders, and hydraulic hammers operate under extreme pressures, abrasive conditions, and varying temperatures, our seal kit provides the crucial resilience needed to prevent fluid leakage, maintain system pressure, and ensure continuous operation, drastically reducing costly downtime. For marine applications, including ship propulsion systems, steering gear, and deck machinery, the kit's superior material compatibility and corrosion resistance—especially against saltwater and corrosive marine fluids—are invaluable, preventing premature seal failure in harsh offshore environments. In agricultural machinery, such as tractors, harvesters, and sprayers, reliable hydraulic systems are essential for operational efficiency. The kit ensures that hydraulic pumps perform optimally, contributing to enhanced fuel economy and extended service intervals, which are key drivers for reducing operational costs for large-scale farming enterprises.

Furthermore, the industrial manufacturing sector, encompassing presses, injection molding machines, and various automation systems, benefits immensely from the kit's ability to restore precision and reliability to hydraulic pumps, ensuring consistent product quality and high throughput. In the petrochemical industry, where pumps handle a variety of aggressive chemicals and hydrocarbons, the FKM components within the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit offer unparalleled chemical resistance, preventing hazardous leaks and ensuring operational safety. For metallurgical plants, which rely on powerful hydraulic systems for processes like rolling and forging, the kit's high-temperature resilience and pressure capabilities ensure the uninterrupted flow of operations under extreme thermal loads. Lastly, in water supply and drainage systems, where pumps operate continuously, the long service life and robust design of the seals contribute significantly to energy savings by maintaining optimal volumetric efficiency and preventing internal bypass, which would otherwise lead to wasted energy and increased pumping costs. The tangible advantages offered by this seal kit include substantial energy savings by minimizing internal leakage, superior corrosion resistance due to advanced material selection, and a significant reduction in overall maintenance frequency and costs, translating directly into enhanced profitability and operational sustainability for our B2B clients.

Strategic Sourcing: Why Our Hydraulic Pump Repair Kit Stands Apart

In a competitive global market, selecting the right supplier for critical components like the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit is a strategic decision that impacts long-term operational efficiency and profitability. While numerous manufacturers offer hydraulic seal solutions, discerning buyers prioritize suppliers who demonstrate unwavering commitment to quality, innovative research and development, and comprehensive customer support. Our company distinguishes itself through a steadfast adherence to these principles, positioning us as a preferred partner for B2B enterprises. Unlike many competitors who may compromise on material quality or manufacturing precision to achieve lower price points, we maintain a stringent quality assurance protocol, sourcing only the highest-grade raw materials and employing state-of-the-art manufacturing technologies. This commitment is evidenced by our robust ISO 9001 certification, a testament to our consistent production of high-quality products that meet international standards. Furthermore, our dedicated R&D team continuously innovates, exploring new materials and seal geometries to enhance performance characteristics such as wear resistance, thermal stability, and chemical compatibility, ensuring our kits remain at the forefront of hydraulic sealing technology.

A key differentiating factor is our robust capability in offering custom solutions. We understand that standard repair kits may not always perfectly address the unique specifications or legacy system requirements of every hydraulic pump. Therefore, we provide comprehensive engineering support to design and manufacture tailored seal kits, leveraging our extensive material expertise and precision manufacturing capabilities. This bespoke service ensures that even highly specialized or obsolete hydraulic pumps can be effectively repaired, extending their life cycle and avoiding costly replacements. Our design process involves detailed consultations with clients to understand their specific operational environment, fluid types, pressure profiles, and temperature ranges, allowing us to recommend or develop the optimal material compositions and seal designs. This collaborative approach underscores our commitment to partnership rather than mere transactional engagement. Moreover, our extensive service history, spanning over two decades in the hydraulic components sector, is a testament to our reliability and deep industry knowledge. We have successfully served a diverse clientele, including leading corporations in heavy machinery, energy, and aerospace, building a reputation for not just supplying products but delivering solutions that drive operational excellence. Choosing our Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit signifies an investment in unmatched quality, tailored engineering, and reliable long-term support, ensuring that your hydraulic assets operate at their peak performance for years to come.

Real-World Impact: Application Cases and Testimonials

The true measure of a product's value lies in its proven performance in real-world scenarios and the positive feedback from satisfied clients. The Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit has consistently delivered exceptional results across various challenging industrial applications, directly translating into tangible operational improvements and significant cost savings for our B2B partners.

- Case Study: Heavy Construction Equipment Fleet Maintenance

A major construction firm operating a fleet of hydraulic excavators faced recurring issues with pump seal failures, leading to extensive fluid loss and unplanned downtime. After integrating our Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit into their preventive maintenance schedule, the firm reported a remarkable 40% reduction in hydraulic fluid consumption over six months due to eliminated leaks, and a 25% increase in Mean Time Between Failures (MTBF) for their hydraulic pumps, significantly enhancing operational continuity and reducing maintenance expenditures. The specialized FKM seals demonstrated superior resistance to the harsh construction site environment, including exposure to dirt and extreme temperature fluctuations. - Case Study: Industrial Press Operations

An automotive parts manufacturer experienced inconsistent pressure output from their hydraulic presses, impacting product quality and production efficiency. Diagnostics revealed degraded pump seals. Following the installation of our seal kit, the manufacturer observed a restoration of consistent operating pressures, with volumetric efficiency returning to over 98% of original specifications. This resulted in a 15% improvement in cycle times and a noticeable reduction in scrap rates, directly boosting their overall production throughput and product quality, showcasing the kit's ability to restore precision in demanding manufacturing environments.

These case studies exemplify how the precise engineering and high-quality materials of our Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit translate into measurable benefits for our clients. Customer feedback consistently highlights the ease of installation, the noticeable improvement in pump performance immediately post-repair, and the long-term reliability provided by our kits. A recent survey of our industrial clients indicated a 95% satisfaction rate regarding product durability and technical support. One client from the marine sector commented, "The seal kits have dramatically reduced our vessel's hydraulic system maintenance needs. We've seen a significant increase in the time between overhauls, which is crucial for our operational schedule." Another from the petrochemical industry stated, "Their custom seal solutions are invaluable. We operate unique, high-pressure pumps, and their team developed a specialized kit that performs flawlessly under our extreme conditions, ensuring compliance with strict safety regulations." These experiences underscore our commitment to not just delivering a product, but providing a comprehensive solution that empowers our clients to achieve their operational goals with enhanced efficiency and reliability, reinforcing our position as a trusted partner in the hydraulic repair industry.

Ensuring Trust: Support, Delivery, and Warranty Commitments

Building and maintaining trust with our B2B clientele is paramount, and it extends beyond the superior quality of our Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit. Our comprehensive customer support framework is designed to provide seamless assistance from initial inquiry through post-purchase support, ensuring a smooth and efficient experience for maintenance managers and procurement specialists.

Frequently Asked Questions (FAQ)

-

Q: How do I identify the correct seal kit for my specific pump model?

A: Our technical support team is available to assist. Provide us with your pump's manufacturer, model number, and any existing part numbers (like 776872, 51V250, Up0803e), and our experts will cross-reference our extensive database to ensure you receive the precise Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit for your equipment. We prioritize accuracy to prevent compatibility issues. -

Q: What is the typical lead time for delivery?

A: For standard kits like the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit, we maintain a robust inventory, allowing for dispatch within 1-3 business days. Custom or large-volume orders may require 5-10 business days, depending on complexity. We utilize efficient global logistics partners to ensure timely and secure delivery to your specified location, minimizing any potential disruption to your operations. -

Q: What is your warranty policy for the seal kits?

A: We stand behind the quality of our products. All our seal kits, including the Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit, come with a 12-month limited warranty against manufacturing defects from the date of purchase. This warranty covers material and workmanship flaws under normal operating conditions. Our commitment ensures that your investment is protected and reflects our confidence in the durability and performance of our products. -

Q: Can you provide installation guidance or technical training?

A: While installation is typically performed by qualified technicians, we offer comprehensive technical documentation and, for larger enterprises, can arrange for remote or on-site technical guidance. Our support team is equipped to answer specific installation queries and provide troubleshooting assistance, ensuring that your team can confidently integrate our seal kits.

Our commitment to delivery efficiency is matched by our robust after-sales support. We understand that in B2B operations, time is money, and any delay can impact production schedules. Therefore, we streamline our order fulfillment process, leveraging advanced inventory management systems to ensure immediate availability for standard kits and efficient production for custom orders. Our global distribution network ensures that your Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit reaches you reliably and swiftly, irrespective of your operational location. Beyond the transaction, our dedicated customer support team remains accessible for any technical queries, post-installation challenges, or further product information. This holistic approach to customer service, underpinned by our decades of industry experience and adherence to international quality standards, provides unparalleled trustworthiness and peace of mind for our industrial clients. We are not just a supplier; we are a long-term partner dedicated to the operational success and efficiency of your hydraulic systems, consistently delivering high-quality solutions and expert support.

Conclusion: The Indispensable Value of Precision Hydraulic Components

In summation, the operational integrity and longevity of hydraulic systems are inextricably linked to the quality of their sealing components. The Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit represents the pinnacle of engineering excellence, designed to meet and exceed the rigorous demands of modern industrial environments. Through meticulous material selection, state-of-the-art manufacturing processes including precision CNC machining and advanced molding techniques, and a comprehensive quality assurance framework, this kit delivers unmatched performance. Its versatility across diverse application scenarios—from heavy construction and mining to marine, agricultural, petrochemical, and metallurgical operations—underscores its critical role in maintaining equipment uptime, optimizing efficiency, and significantly extending the service life of hydraulic pumps. The intrinsic advantages of energy savings through superior sealing, exceptional corrosion resistance, and a dramatic reduction in unscheduled downtime directly translate into a compelling return on investment for businesses seeking to enhance their operational resilience and profitability.

Our commitment to the highest standards of quality, backed by internationally recognized certifications like ISO 9001, combined with our proven track record of delivering reliable solutions and offering bespoke customization capabilities, differentiates us in a crowded market. The tangible success stories and testimonials from our global clientele are a testament to the transformative impact of our repair kits on their operations. By choosing our Hydraulic Pump Repair Kit 776872 51V250 Up0803e seal kit, B2B decision-makers are not merely procuring a product; they are investing in a partnership that promises unparalleled technical expertise, robust after-sales support, and a steadfast commitment to ensuring the long-term efficiency and reliability of their critical hydraulic assets. This strategic investment in high-quality components is an imperative for any enterprise aiming to minimize operational costs, maximize productivity, and secure a sustainable competitive advantage in today's demanding industrial landscape. We invite you to experience the definitive difference that precision engineering and unwavering quality can make to your hydraulic system performance.

References

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications. ASTM International.

- ISO 1817: Rubber, vulcanized or thermoplastic – Determination of the effect of liquids. International Organization for Standardization.

- Hydraulic Fluid Power – Sealing Devices – Glossary of Terms. SAE International.

- Fundamentals of Fluid Sealing Technology. Fluid Sealing Association (FSA).

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories