Sep . 07, 2024 02:08 Back to list

Hydraulic Gear Pump Seals - High Quality Sealing Solutions

Understanding Hydraulic Gear Pump Seals

Hydraulic gear pumps are essential components in various industrial systems, providing the necessary pressure and flow for hydraulic machinery. One critical aspect of these pumps is their seals. Hydraulic gear pump seals are vital for maintaining the integrity and efficiency of the pump while preventing fluid leaks, which can lead to significant operational issues and increased maintenance costs.

Hydraulic gear pumps function by using two interlocking gears that rotate within a housing. As the gears rotate, they create a vacuum on the inlet side, drawing hydraulic fluid into the pump. The fluid is then displaced through the outlet, generating pressure to power hydraulic systems. However, for this process to be successful, effective sealing mechanisms must be in place.

Seals in hydraulic gear pumps serve multiple purposes. Firstly, they prevent hydraulic fluid from leaking out of the pump, which is crucial for maintaining operational efficiency. Any fluid loss can result in decreased pressure and performance, as well as potential damage to other components of the hydraulic system. Additionally, effective seals help keep contaminants out, preserving the quality of the hydraulic fluid and extending the life of the pump.

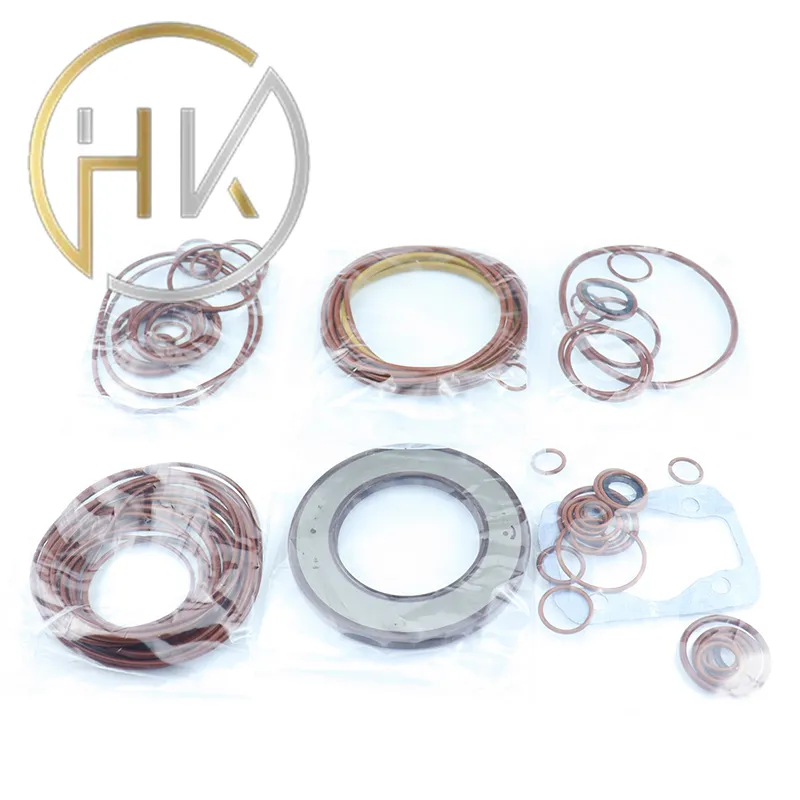

hydraulic gear pump seals

There are several types of seals used in hydraulic gear pumps, each designed to meet specific requirements. Common types include O-rings, lip seals, and mechanical seals. O-rings are widely used due to their versatility and ability to create a tight seal at low pressures. Lip seals, on the other hand, are effective for high-pressure applications and can accommodate some misalignment, making them ideal in dynamic situations. Mechanical seals provide an extra layer of security against leaks, particularly in heavy-duty applications.

The choice of sealing material is another critical consideration. Common materials include nitrile rubber, fluorocarbon, and polyurethane, each offering different levels of resistance to temperature, pressure, and chemical exposure. Selecting the right material ensures that the seals can withstand the specific operating conditions of the hydraulic pump.

Regular maintenance and inspection of hydraulic gear pump seals are essential for optimal performance. Over time, seals can wear out due to friction, heat, and exposure to harsh fluids. Routine checks can identify signs of wear or damage early, allowing for timely replacements and preventing larger issues from arising.

In conclusion, hydraulic gear pump seals are crucial for the efficiency and reliability of hydraulic systems. By preventing leaks and protecting against contaminants, they play a significant role in maintaining the functionality of hydraulic pumps. Understanding the types of seals and their materials can help operators make informed decisions, ensuring long-term performance and reducing operational costs. Regular maintenance and timely replacement of seals further enhance the durability of hydraulic gear pumps, ultimately contributing to the smooth operation of industrial machinery.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories