Sep . 07, 2024 01:53 Back to list

Excavator Boom Cylinder Seal Replacement Guide

Excavator Boom Cylinder Seal Replacement A Comprehensive Guide

Excavators are integral machines in construction and excavation projects, designed for heavy-duty tasks. Among their many components, the boom cylinder plays a critical role in controlling the movement of the boom, allowing operators to maneuver with precision. Over time, the seals within the boom cylinder can wear out due to constant exposure to hydraulic fluids, debris, and extreme operating conditions. When this happens, it’s essential to perform a seal replacement to maintain the excavator's optimal performance. Here’s a comprehensive guide to understanding the importance of seal replacement and the steps involved in the process.

Why Seal Replacement is Necessary

Boom cylinder seals ensure that hydraulic fluid remains contained within the cylinder, allowing for smooth and efficient movement. Worn or damaged seals can lead to hydraulic fluid leaks, reducing the efficiency of the cylinder and causing power loss. This can manifest as sluggish or jerky movements, ultimately affecting the machine’s overall performance. Additionally, hydraulic fluid leaks are not only wasteful but can also pose safety hazards and environmental concerns. Regular inspections and timely seal replacements can prevent larger mechanical issues down the line, extending the life of your excavator.

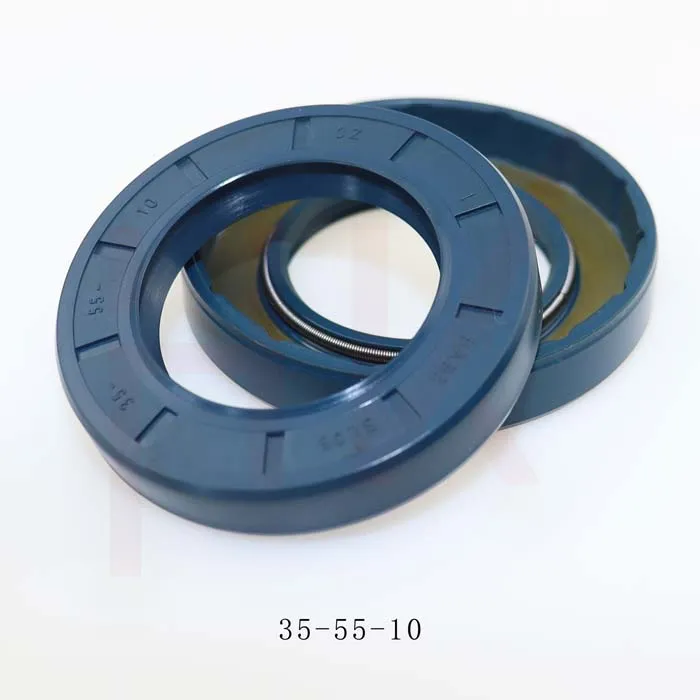

Tools and Materials Needed

Before beginning the seal replacement, gather the necessary tools and materials - Hydraulic seal kit (specific to your excavator model) - Socket set and wrenches - Screwdrivers - Pliers - Torque wrench - Hydraulic jack or lift - Clean cloths and degreaser - Safety goggles and gloves

Step-by-Step Replacement Process

1. Safety First Always start by ensuring the excavator is parked on level ground, the hydraulic system is depressurized, and all safety precautions are in place.

2. Remove the Boom Cylinder Using a hydraulic jack, lift the boom to access the cylinder. Disconnect the hydraulic lines, noting their positions for reassembly later.

excavator boom cylinder seal replacement

3. Disassemble the Cylinder Remove the end caps and any holding bolts. Gently slide off the outer casing to expose the internal components of the cylinder.

4. Remove Old Seals Carefully extract the old seals using pliers or a seal removal tool. Take care not to scratch the cylinder surfaces, as this can lead to premature seal failure.

5. Clean the Cylinder Before installing new seals, thoroughly clean the cylinder's interior and exterior. Use a degreaser and cloth to remove any residual hydraulic fluid and debris.

6. Install New Seals Carefully install the new seals from the seal kit. Ensure that they are seated properly in their respective grooves, as any misalignment can result in further leaks.

7. Reassemble the Cylinder Once new seals are in place, reattach the outer casing and end caps. Tighten bolts to specified torque settings to avoid leaks.

8. Reinstall the Boom Cylinder Reverse the earlier disassembly steps to reinstall the boom cylinder onto the excavator. Reconnect hydraulic lines, ensuring they are secure and correctly positioned.

9. Test the System Once everything is reassembled, power up the hydraulic system and test the boom's movement. Check for leaks and ensure smooth operation.

Conclusion

Replacing the seals in an excavator boom cylinder is a crucial maintenance task that can significantly impact the machine's performance and longevity. By following the outlined steps and ensuring regular maintenance checks, operators can safeguard their equipment against the detrimental effects of seal wear and hydraulic fluid leaks. Remember, when in doubt, consulting with a professional or referring to the manufacturer's guidelines can always help ensure a successful seal replacement.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories