Feb . 14, 2025 21:27 Back to list

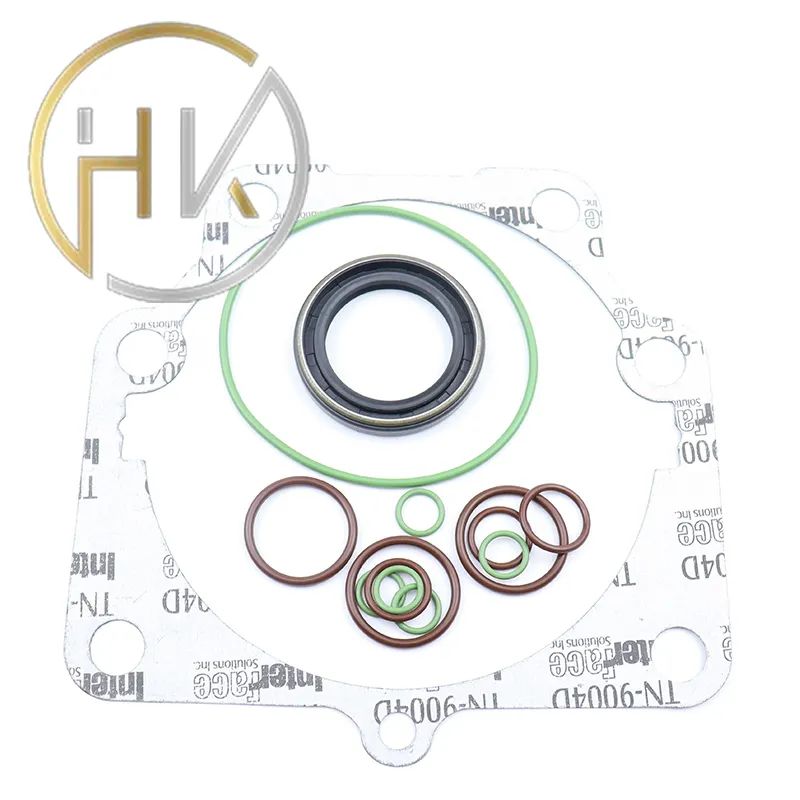

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Experience in implementing these seals reveals that successful application demands precision during installation. Improper installation can lead to premature failure, posing risks of system downtime or catastrophic failure. This underscores the importance of utilizing skilled technicians who are familiar with the delicate handling and fitting processes high pressure shaft seals require. Their expertise ensures longevity and effectiveness, minimizing operational disruptions and maintenance costs. Authority in this domain is demonstrated by companies that continuously innovate seal technology, pushing the boundaries of what’s possible. Leading manufacturers invest heavily in research and development to tailor solutions for new challenges, such as those posed by increasingly stringent environmental regulations and the demand for more sustainable practices. These companies often collaborate with industrial experts to validate performance through rigorous testing protocols, further strengthening trust in their products. The trustworthiness of high pressure shaft seals is enhanced through certifications and compliance with international standards. Industry-standard certifications ensure that seals meet safety and quality benchmarks required for high-stakes applications. Additionally, transparent customer support and comprehensive warranty policies contribute to consumer confidence, providing assurance in their long-term performance. In conclusion, high pressure shaft seals are pivotal to maintaining efficiency and safety in high-demand operational environments. Their development and application are supported by a deep understanding of materials, adherence to installation precision, and continuous innovation by authoritative manufacturers. By ensuring proper selection and installation, companies can significantly enhance the reliability and lifespan of their machinery, thus optimizing their operations and reducing unforeseen complications. These combined efforts in expertise, experience, authoritativeness, and trustworthiness drive the sustained success and confidence in high pressure shaft seals across industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories