Jul . 31, 2024 21:01 Back to list

High-Performance Rotary Shaft Seals for Extreme Pressure Applications and Enhanced Equipment Longevity

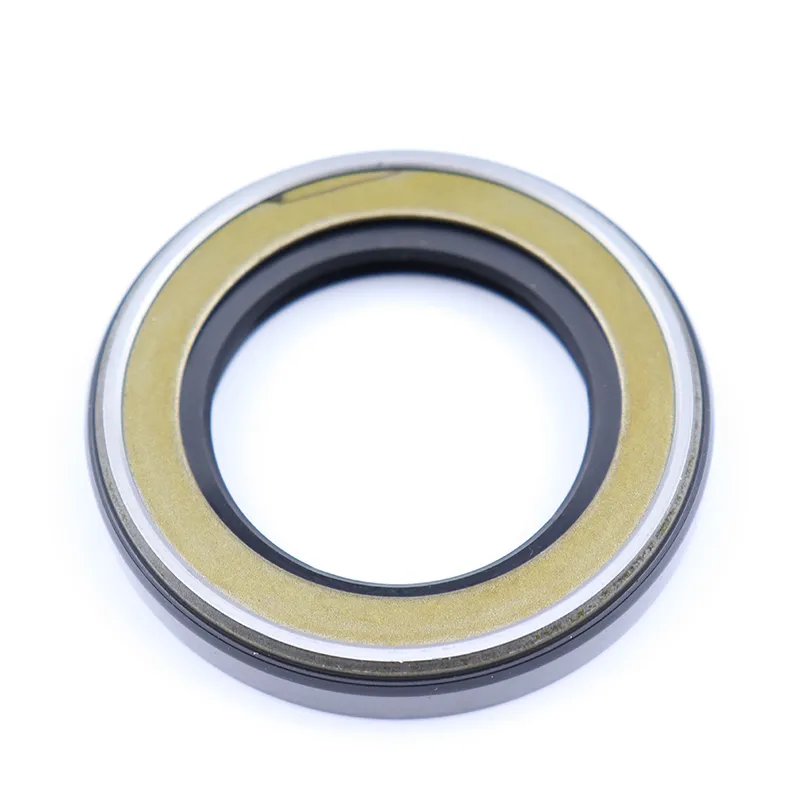

High Pressure Rotary Shaft Seals An Overview

In the realm of mechanical engineering, the importance of effectively sealing rotating shafts cannot be overstated. High pressure rotary shaft seals play a critical role across various industries, including oil and gas, automotive, and manufacturing, where the integrity of fluid containment is essential. These seals are engineered to handle extreme pressure conditions while ensuring minimal leakage, thus significantly enhancing the efficiency and longevity of machinery.

Function and Design

High pressure rotary shaft seals are designed to prevent the escape of fluids or contaminants from a rotating shaft. Their primary function is to retain lubricants within the machinery while blocking external contaminants such as dust, dirt, and moisture from entering. This is particularly crucial in high-stakes environments where equipment operates under great stress.

The design of these seals typically includes a flexible elastomeric lip which exerts a sealing force against the shaft. This lip deforms slightly during operation, allowing it to conform to the surface of the shaft and create a tight seal. In addition, high pressure seals often incorporate advanced materials such as fluoropolymers and composites to ensure durability and resistance to aggressive fluids, temperature changes, and wear.

Material Considerations

The selection of materials for high pressure rotary shaft seals is pivotal. These seals must withstand not only the high pressures typical of industrial applications but also chemical exposure from lubricants and other fluids. Materials such as polyurethane, silicone, and nitrile rubber are commonly used, each offering distinct advantages in terms of temperature resistance, chemical compatibility, and physical properties.

For instance, fluorocarbon-based seals are renowned for their exceptional chemical resistance and ability to operate at high temperatures, making them ideal for applications involving aggressive chemicals or extreme heat. On the other hand, nitrile rubber is often favored in hydraulic systems due to its superior resilience and capability to handle oils and fuels.

high pressure rotary shaft seal

Applications

High pressure rotary shaft seals are ubiquitous in various applications. In the automotive industry, they are vital in ensuring the efficiency of engines by preventing oil leaks and maintaining lubrication. In the oil and gas sector, these seals are crucial for equipment operating under high pressure, such as pumps and compressors, where even a minor leak can lead to significant operational issues and safety hazards.

Moreover, manufacturing machines frequently rely on these seals to maintain operational integrity in hydraulic systems, conveyors, and mixers

. As industries continue to evolve, the demand for high performance, reliable rotary shaft seals grows, prompting advances in design and material technology.Challenges and Innovations

Despite their critical importance, high pressure rotary shaft seals face challenges, particularly related to wear, temperature fluctuations, and compatibility with new synthetic fluids. Innovators in the field are continuously exploring advanced designs and materials that can enhance the performance of these seals. For example, the integration of nanotechnology and smart materials is showing promise in creating seals that can adapt to varying operational conditions, thus extending service life and improving performance.

Conclusion

High pressure rotary shaft seals are an essential component in modern machinery, providing necessary protection against fluid leakage and contamination in high-pressure environments. With advancing technologies and materials, the future of these seals looks promising, allowing industries to enhance efficiency, safety, and productivity. As the demand for robust, reliable sealing solutions grows, ongoing research and development will undoubtedly pave the way for innovations that meet the ever-evolving challenges of modern industrial applications.

-

Durable 22x35x6 TCV Oil Seals: FKM & NBR for Hydraulic Pumps

NewsSep.01,2025

-

Cassette Seal 15018014.5/16 Hub Oil Seal | OEM Quality 000051785

NewsAug.31,2025

-

DKBI Hydraulic Wiper Seal 20x32x6/9 | Dustproof & Standard Oil Seal

NewsAug.30,2025

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

NewsAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

NewsAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

Products categories