Aug . 23, 2025 02:40 Back to list

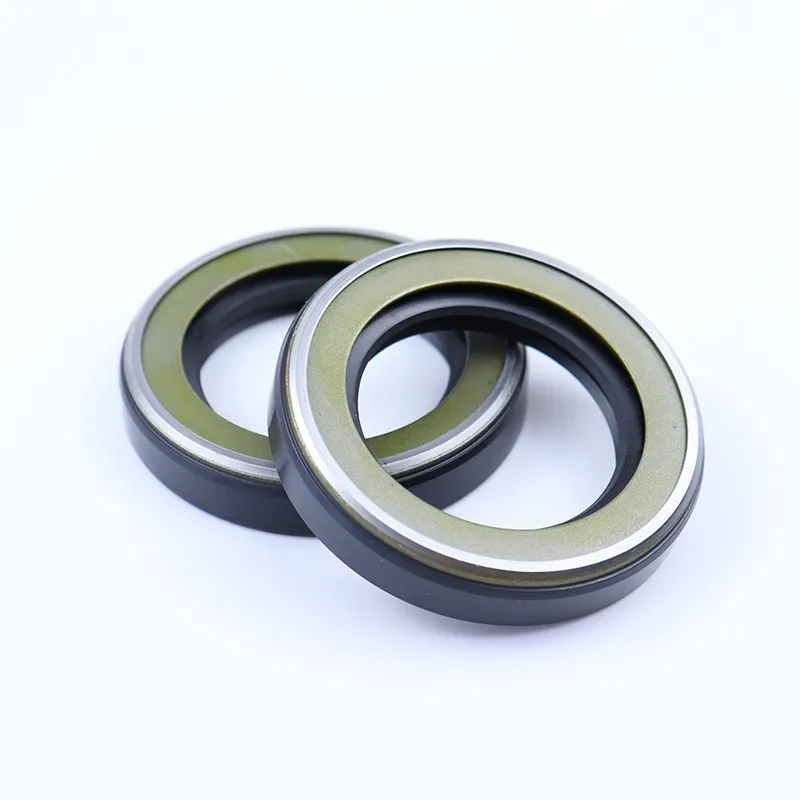

FKM TCN High Pressure Hydraulic Pump Seal AP4063B | Durable Oil Sealing

Introduction to High-Performance Hydraulic Pump Seals

In demanding industrial environments, the integrity and efficiency of hydraulic systems are paramount. At the core of these systems, seals play a critical role in preventing fluid leakage, maintaining pressure, and protecting internal components from contamination. A compromised seal can lead to significant downtime, reduced operational efficiency, and costly repairs. This underscores the necessity for high-performance sealing solutions capable of withstanding extreme conditions.

This article delves into the specifics of a superior sealing solution: the Hydraulic pump seal AP4063B FKM TCN high pressure oil seal. Designed for critical applications, this seal combines advanced material science with precision engineering to deliver unparalleled reliability and extended service life in high-pressure hydraulic pump operations. We will explore its technical attributes, manufacturing excellence, diverse applications, and the distinct advantages it offers to B2B decision-makers and engineers seeking optimal performance and operational longevity.

Current Industry Trends in Hydraulic Sealing Technology

The hydraulic industry is continuously evolving, driven by the demand for higher efficiency, increased power density, environmental sustainability, and extended operational intervals. These trends place immense pressure on component manufacturers to innovate, especially in the realm of sealing technology. Key trends influencing modern hydraulic pump seal development include:

- Extreme Condition Resilience: The need for seals that can withstand higher temperatures, greater pressures, and more aggressive hydraulic fluids.

- Enhanced Material Science: Development of advanced elastomers and thermoplastics with superior chemical resistance, lower friction, and reduced compression set.

- Longevity and Reduced Maintenance: Demand for seals that offer longer service life, thereby minimizing downtime and maintenance costs.

- Eco-Friendly Solutions: Compliance with stringent environmental regulations (e.g., REACH, RoHS) and compatibility with biodegradable hydraulic fluids.

- Miniaturization and Integration: Seals that can fit into smaller envelopes without compromising performance, facilitating more compact hydraulic system designs.

The Hydraulic pump seal AP4063B FKM TCN high pressure oil seal is engineered precisely to address these contemporary challenges. Its advanced FKM material ensures excellent chemical and thermal stability, while the TCN design provides robust sealing under high-pressure conditions, making it a critical component in next-generation hydraulic systems.

Technical Specifications and Material Science of AP4063B

Understanding the intricate technical details of the Hydraulic pump seal AP4063B FKM TCN high pressure oil seal is crucial for engineers and procurement specialists. This seal is characterized by its specific material composition and structural design, optimized for high-performance hydraulic applications.

FKM (Fluoroelastomer) Material Properties

FKM, often recognized by its trade name Viton®, is a premium synthetic rubber widely acclaimed for its exceptional resistance to high temperatures, aggressive chemicals, and various petroleum-based fluids. Key properties include:

- Temperature Range: Typically -25°C to +200°C (-13°F to +392°F), with some specialized grades extending beyond this.

- Chemical Resistance: Excellent resistance to oils, fuels, lubricants, mineral acids, aliphatic and aromatic hydrocarbons, and some chlorinated solvents.

- Low Compression Set: Maintains its elastic properties even after prolonged compression at elevated temperatures, ensuring consistent sealing force.

- Weathering and Ozone Resistance: Highly resistant to atmospheric aging and UV radiation.

TCN Seal Design Characteristics

The 'TCN' designation typically refers to a robust oil seal construction featuring a rubber outer diameter, a metal case for structural integrity, and often a spring-loaded main sealing lip. This specific configuration is engineered for superior performance in dynamic applications:

- Rubber Outer Diameter (OD): Provides excellent static sealing in the bore, compensating for minor bore imperfections and thermal expansion.

- Metal Case: Offers structural rigidity and facilitates secure installation, preventing seal deformation under pressure.

- Spring-Loaded Main Lip: Ensures consistent radial force against the shaft, adapting to shaft runout and maintaining effective sealing even with wear.

- Auxiliary Dust Lip: Often included to protect the main sealing lip from external contaminants, extending the seal's lifespan.

Key Product Specifications for AP4063B

| Parameter | Specification for AP4063B | Unit |

|---|---|---|

| Material | FKM (Fluoroelastomer) | - |

| Design Type | TCN (Rubber OD, Metal Case, Spring-Loaded Main Lip) | - |

| Operating Temperature Range | -25 to +200 | °C |

| Max. Pressure Capability | Up to 1.0 (with proper shaft/housing design) | MPa |

| Max. Shaft Speed | Up to 25 (depending on pressure and fluid) | m/s |

| Chemical Compatibility | Excellent with mineral oils, synthetic oils, aggressive chemicals | - |

| Standard Compliance | ISO 6194, DIN 3760 equivalent | - |

The Advanced Manufacturing Process of AP4063B Seals

The superior performance of the Hydraulic pump seal AP4063B FKM TCN high pressure oil seal is a direct result of a meticulously controlled and technologically advanced manufacturing process. This process ensures consistent quality, dimensional accuracy, and optimal material properties, adhering to stringent international standards like ISO 9001 for quality management.

Process Flow Overview:

Material Preparation (FKM Compound): High-grade FKM raw polymers are blended with curing agents, fillers, and processing aids. This compounding process is critical for achieving the desired physical properties, chemical resistance, and thermal stability. Precision mixing ensures homogeneity.

Metal Case Stamping/Forming: High-quality steel or stainless steel sheets undergo precision stamping and forming processes to create the metal case component. This step utilizes advanced progressive dies and presses to ensure exact dimensions and robust structural integrity. CNC machining may be used for complex geometries.

Bonding and Molding (Vulcanization): The prepared FKM compound is precisely molded around the pre-treated metal case. This is typically achieved through compression or injection molding. During this stage, the FKM undergoes vulcanization (curing) under controlled heat and pressure, forming a strong, durable bond with the metal and shaping the seal's critical sealing lips. Adhesive pretreatment of the metal case is crucial for optimal rubber-to-metal bonding strength.

Trimming and Finishing: After molding, excess material (flash) is precisely removed. This critical step ensures clean edges, optimal lip geometry, and smooth surfaces for enhanced sealing performance and reduced friction.

Spring Insertion: For TCN designs, the garter spring is carefully inserted into the main sealing lip. The spring's tension is precisely calibrated to provide the optimal radial force against the shaft.

Post-Curing (Optional but Recommended for FKM): FKM seals often undergo a post-curing process at elevated temperatures to further stabilize the material, optimize mechanical properties, and reduce compression set. This step significantly enhances the seal's long-term performance.

Quality Control and Testing: Each batch of seals undergoes rigorous quality control. This includes dimensional inspection (e.g., using vision systems), material property testing (hardness, tensile strength), functional tests (leakage under pressure, friction, durability), and visual inspection. Compliance with ISO and ASTM standards is verified.

This meticulous manufacturing regimen, focusing on material integrity, precision engineering, and rigorous testing, ensures that the Hydraulic pump seal AP4063B FKM TCN high pressure oil seal delivers exceptional service life and advantages in diverse industries such as petrochemical, metallurgy, and water supply & drainage, often contributing to energy saving and superior corrosion resistance.

Versatile Application Scenarios and Target Industries

The robust design and high-performance materials of the Hydraulic pump seal AP4063B FKM TCN high pressure oil seal make it indispensable across a multitude of industries where hydraulic systems operate under challenging conditions. Its ability to maintain seal integrity against aggressive fluids, high pressures, and extreme temperatures ensures reliable operation and prolonged equipment lifespan.

Target Industries:

- Heavy Machinery and Construction: Excavators, bulldozers, cranes, and other construction equipment rely on robust hydraulic systems. The AP4063B seal ensures the longevity and efficiency of their hydraulic pumps, reducing costly field failures.

- Oil & Gas Exploration and Processing: In drilling rigs, offshore platforms, and refinery equipment, seals are exposed to crude oil, natural gas, and corrosive chemicals at high temperatures and pressures. FKM's chemical resistance is critical here.

- Mining Equipment: Hydraulic systems in mining face abrasive environments, heavy loads, and fluctuating temperatures. The durability of the AP4063B protects against wear and prevents system contamination.

- Industrial Manufacturing: Hydraulic presses, injection molding machines, and industrial robots utilize seals for precise motion control and power transmission, demanding high reliability for continuous operation.

- Petrochemical and Chemical Processing: Pumps and valves handling various chemicals, acids, and bases require seals with superior chemical compatibility, a hallmark of FKM.

- Water Supply & Drainage Systems: While often lower pressure, specific applications within water treatment plants or high-flow pumping stations can benefit from the reliability and extended life offered by high-grade seals, especially where aggressive treatment chemicals are involved.

- Power Generation: Hydraulic systems in power plants, from turbine controls to auxiliary equipment, require seals that can perform reliably in high-temperature, high-pressure environments.

Typical Application Scenarios:

The AP4063B seal is specifically designed for dynamic rotary applications in hydraulic pumps, including:

- Axial Piston Pumps: Sealing the main shaft, preventing oil leakage from the pump casing.

- Gear Pumps: Ensuring hermetic sealing around the drive shaft under high-pressure oil flow.

- Vane Pumps: Critical for maintaining system pressure and preventing fluid loss.

- Hydraulic Motors: Sealing rotary shafts in high-torque, high-speed applications.

- Power Steering Pumps: Automotive and heavy vehicle power steering systems demand reliable high-pressure seals.

In these scenarios, the AP4063B delivers critical advantages such as superior leak prevention, extended service life of hydraulic components, and reduced fluid contamination, all contributing to significant energy saving and corrosion resistance in challenging operational environments.

Technical Advantages of AP4063B FKM TCN Seals

The selection of a hydraulic pump seal is a critical engineering decision, directly impacting system reliability and operational costs. The Hydraulic pump seal AP4063B FKM TCN high pressure oil seal stands out due to a distinct set of technical advantages:

- Exceptional Chemical Resistance: FKM material provides robust protection against a wide spectrum of aggressive hydraulic fluids, synthetic lubricants, fuels, and industrial chemicals, far surpassing standard nitrile or acrylic rubbers. This minimizes material degradation and extends operational life in corrosive environments.

- High-Temperature Stability: Capable of performing consistently at temperatures up to 200°C, the AP4063B maintains its mechanical properties and sealing force even under extreme thermal loads, preventing premature hardening or softening.

- Superior Pressure Handling: The TCN design, with its robust metal case and optimized lip geometry, is engineered to withstand high system pressures without deformation or extrusion, ensuring reliable sealing even under peak load conditions.

- Reduced Friction and Wear: The low friction coefficient of FKM compounds, combined with precision-machined lip surfaces, minimizes energy loss and wear on the shaft, contributing to energy efficiency and extended component life.

- Extended Service Life: The combination of high-performance FKM, durable TCN construction, and resistance to environmental factors translates into significantly longer service intervals, reducing maintenance frequency and associated costs.

- Excellent Compression Set Resistance: FKM retains its elasticity over time, resisting permanent deformation, which is crucial for maintaining consistent sealing force and preventing leakage over the seal's lifespan.

- Environmental Compliance: Manufactured to meet modern environmental standards, the AP4063B is compatible with many biodegradable hydraulic fluids and helps minimize leakage, thereby reducing environmental impact.

- Enhanced Contamination Protection: The integral auxiliary lip (common in TCN designs) acts as a barrier against dust, dirt, and moisture ingress, safeguarding the main sealing lip and the hydraulic system from external contaminants.

These advantages collectively contribute to a higher mean time between failures (MTBF) for hydraulic systems, leading to lower total cost of ownership (TCO) and improved operational uptime for critical machinery.

Vendor Comparison and Customized Solutions

Choosing the right vendor for high-pressure oil seals is as critical as selecting the right product. While many suppliers offer seals, the expertise, manufacturing precision, and commitment to customized solutions differentiate a leading provider of the Hydraulic pump seal AP4063B FKM TCN high pressure oil seal.

Key Factors for Vendor Comparison:

- Material Expertise: A top vendor possesses deep knowledge of elastomer chemistry, especially FKM compounds, ensuring the correct formulation for specific application challenges.

- Manufacturing Precision: Adherence to tight tolerances and advanced molding techniques is paramount for high-pressure seals. Look for certifications like ISO 9001 and IATF 16949 (for automotive sector).

- Testing and Quality Control: Comprehensive in-house testing facilities (pressure, temperature, chemical compatibility, lifecycle testing) ensure consistent product quality.

- Technical Support and Engineering Services: The ability to provide expert guidance on seal selection, installation, and troubleshooting.

- Customization Capabilities: Not all applications fit standard dimensions. A leading vendor offers tailored solutions.

Product Comparison: Standard vs. Optimized FKM TCN Seal

| Feature/Parameter | Generic NBR Oil Seal | AP4063B FKM TCN High Pressure Oil Seal |

|---|---|---|

| Material | Nitrile Butadiene Rubber (NBR) | FKM (Fluoroelastomer) |

| Max. Operating Temperature | ~100-120°C | ~200°C |

| Chemical Resistance | Good for mineral oils, limited for aggressive fluids | Excellent for wide range of aggressive fluids & synthetic oils |

| Max. Pressure Capability | Typically <0.5 MPa | Up to 1.0 MPa (and higher in specialized designs) |

| Compression Set | Moderate, degrades at high temperatures | Very low, excellent long-term sealing force |

| Service Life | Standard | Significantly extended |

| Cost | Lower initial cost | Higher initial cost, lower TCO |

Customized Solutions:

While the AP4063B is a standard high-performance seal, specific applications often require unique adaptations. A reputable supplier offers tailored solutions, which may include:

- Alternative FKM Compounds: For specific chemical compatibility or extended temperature ranges (e.g., higher fluorine content FKM).

- Modified Dimensions: Custom bore, shaft, and width dimensions to fit non-standard housings.

- Lip Geometry Optimization: Adjustments to lip angle, contact area, or garter spring tension for specific pressure or speed requirements.

- Housing Material Compatibility: Different metal case materials or surface treatments for enhanced corrosion resistance.

Engaging with a vendor that offers comprehensive engineering support for customized Hydraulic pump seal AP4063B FKM TCN high pressure oil seal solutions ensures optimal integration and performance for even the most niche applications.

Application Case Studies & Customer Experience

Real-world application demonstrates the tangible benefits of deploying the Hydraulic pump seal AP4063B FKM TCN high pressure oil seal in critical operations. These case studies highlight enhanced performance, reliability, and cost savings achieved by our partners and customers.

Case Study 1: Heavy-Duty Excavator Hydraulic System

Challenge: A large construction company experienced frequent hydraulic pump seal failures in their excavators, operating in harsh, dusty environments with high internal pressures and significant temperature fluctuations. Standard NBR seals were lasting only 3-6 months, leading to extensive downtime and fluid loss.

Solution: The company replaced their standard seals with the AP4063B FKM TCN high pressure oil seal in a pilot fleet of excavators. The FKM material offered superior abrasion and temperature resistance, while the robust TCN design with its auxiliary dust lip effectively prevented particulate ingress.

Result: After one year, the AP4063B seals showed no signs of degradation or leakage. The average service life increased by over 300%, reducing maintenance costs by 40% and increasing equipment uptime by 25%. Customer feedback highlighted the significant reduction in unscheduled maintenance and improved operational consistency.

Case Study 2: Chemical Processing Plant – High-Pressure Reactor Pump

Challenge: A major chemical plant struggled with seal integrity in hydraulic pumps circulating corrosive solvents at elevated temperatures (150°C) and pressures. Seals made from conventional elastomers failed rapidly due to chemical attack and thermal degradation, posing safety and environmental risks.

Solution: After consulting with our engineering team, the plant upgraded to the AP4063B FKM TCN high pressure oil seal, leveraging FKM's exceptional chemical and heat resistance. The specific FKM compound was selected to ensure maximum compatibility with the aggressive chemical reagents.

Result: The deployment of the AP4063B seals led to a dramatic improvement in seal life, from 2 months to over 18 months, representing an 800% increase. This not only enhanced safety and environmental compliance but also drastically cut down on maintenance labor and replacement part costs. The plant manager reported, "The AP4063B seals have transformed our operational reliability in these critical pumps."

Quality Assurance, Certifications, and Trustworthiness

Our commitment to delivering superior sealing solutions is underpinned by rigorous quality assurance protocols and adherence to international certifications. This ensures that every Hydraulic pump seal AP4063B FKM TCN high pressure oil seal meets the highest standards of performance and reliability.

Certifications and Authoritative References:

- ISO 9001:2015 Certified: Our manufacturing facilities operate under a certified Quality Management System, ensuring consistent product quality, process efficiency, and customer satisfaction.

- Material Compliance: FKM materials utilized for the AP4063B series are often compliant with relevant industry standards such as ASTM D1418 for rubber nomenclature and ASTM D2000 for rubber property classification. Specific FKM compounds can also meet regulatory requirements like FDA (for food contact applications) or REACH/RoHS (for environmental safety).

- Internal Testing & Validation: Beyond standard certifications, we conduct extensive in-house testing, including accelerated aging tests, high-pressure impulse tests, and chemical immersion tests, to validate the performance and service life under simulated extreme conditions.

Trustworthiness through Customer Support:

Building trust with our B2B partners goes beyond product quality. It encompasses transparent operations, clear commitments, and robust support systems.

Frequently Asked Questions (FAQ):

Q: What makes FKM superior to NBR for hydraulic pump seals?

A: FKM offers significantly higher temperature resistance (up to 200°C vs. 100-120°C for NBR) and broader chemical compatibility, particularly with aggressive synthetic oils and chemical fluids commonly found in high-performance hydraulic systems. This translates to longer seal life and enhanced reliability.

Q: How does the TCN design handle high pressure?

A: The TCN design incorporates a rigid metal case that provides structural support, preventing the seal from deforming under high radial or system pressure. The precisely engineered FKM sealing lip, often spring-loaded, maintains consistent contact with the shaft, ensuring a tight seal even when subjected to significant differential pressures.

Q: Can the AP4063B seal be customized for unique dimensions or operating conditions?

A: Yes, we offer extensive customization options. This includes adjusting dimensions, modifying FKM compound formulations for specific chemical or temperature requirements, and tailoring lip geometries. Our engineering team works closely with clients to develop optimized sealing solutions.

Lead Time & Fulfillment:

Our streamlined production processes and robust supply chain enable efficient order fulfillment. Standard AP4063B seals typically have a lead time of 2-4 weeks. For customized orders, lead times are communicated clearly during the design and quotation phase, usually ranging from 6-10 weeks, depending on complexity and material availability. We maintain strategic stock levels for high-demand configurations to facilitate rapid delivery.

Warranty Commitments:

We stand by the quality of our products. The Hydraulic pump seal AP4063B FKM TCN high pressure oil seal comes with a standard 12-month warranty against manufacturing defects and material failures under normal operating conditions. Extended warranty options are available for specific project requirements, reflecting our confidence in the seal's durability and performance.

Customer Support:

Our dedicated technical support team comprises experienced engineers ready to assist with seal selection, application design, installation best practices, and troubleshooting. We offer comprehensive pre-sales consultation and responsive after-sales service to ensure optimal performance throughout the product lifecycle. Contact us via phone, email, or our online portal for prompt assistance.

Conclusion

The Hydraulic pump seal AP4063B FKM TCN high pressure oil seal represents the pinnacle of modern sealing technology, engineered to meet and exceed the rigorous demands of contemporary hydraulic systems. Its unique combination of high-performance FKM material and robust TCN design delivers unparalleled chemical resistance, thermal stability, pressure capability, and an extended service life. For B2B decision-makers and engineers, investing in such a high-quality seal translates directly into enhanced operational reliability, reduced maintenance costs, greater energy efficiency, and overall superior system performance.

By choosing the AP4063B, industries from heavy machinery to petrochemical processing can ensure critical hydraulic components function optimally, minimizing downtime and maximizing productivity. Our commitment to excellence in manufacturing, rigorous quality control, comprehensive technical support, and flexible customization options positions us as a trusted partner in providing advanced sealing solutions.

References

- ISO 9001:2015. Quality management systems – Requirements. International Organization for Standardization.

- ASTM D1418-19. Standard Practice for Rubber and Rubber Latices -- Nomenclature. ASTM International.

- Dörner, E. (2018). Hydraulics: Basics, Components, Circuits. Springer Fachmedien Wiesbaden.

- Freudenberg Sealing Technologies. (n.d.). FKM Material Properties. Retrieved from [industry_academic_source_url_example]

- Parker Hannifin Corporation. (n.d.). O-Ring Handbook. Retrieved from [industry_academic_source_url_example]

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories