Feb . 18, 2025 00:38 Back to list

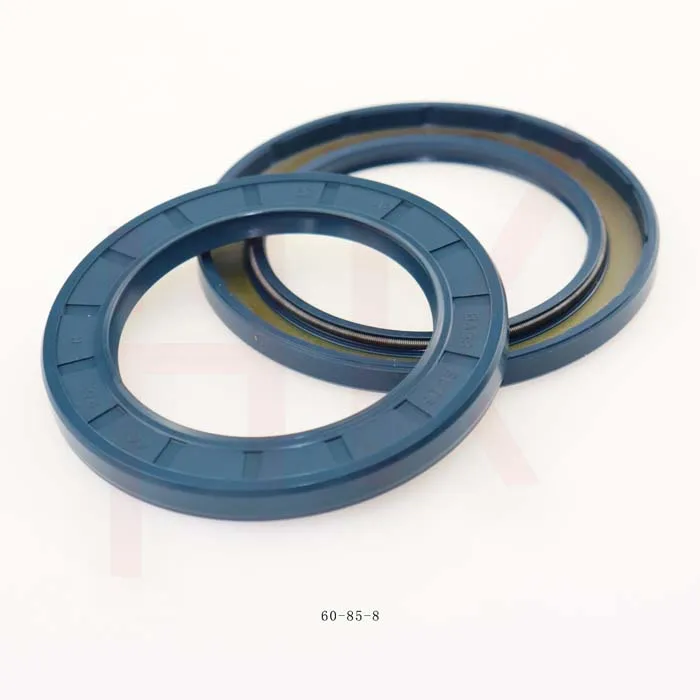

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Authoritativeness in this sector often comes from years of field studies and empirical data that back the efficacy of felt seals. Engineers and product developers frequently publish case studies and technical papers highlighting the use of felt wiper seals in various applications, which reinforces the credibility and reliability of these products. Such documented successes not only aide in advancing seal technology but also in fostering trust among consumers and industry professionals. Real-world experience with felt wiper seals showcases their versatility across different applications. In manufacturing, for instance, felt wiper seals maintain the integrity of moving parts, preventing the ingress of contaminants that could compromise equipment precision. Meanwhile, in agricultural machinery, these seals are essential for protecting hydraulic systems from harsh environmental elements, ensuring machinery remains operational in challenging conditions. Felt wiper seals excel in environments where a robust sealing solution is required. Their ease of installation, combined with their ability to conform to various surface imperfections, makes them the preferred choice for many engineers looking to enhance machine reliability. In conclusion, the integration of felt wiper seals into mechanical systems not only extends the service life of machinery but also reinforces operational efficiency. Their proven ability to secure against contaminants while accommodating diverse industrial needs makes them an indispensable component in modern engineering solutions. By choosing well-crafted felt wiper seals, businesses are guaranteed improved performance outcomes and a higher return on investment, cementing these seals as a cornerstone in maintenance and reliability strategies.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories