Feb . 18, 2025 00:03 Back to list

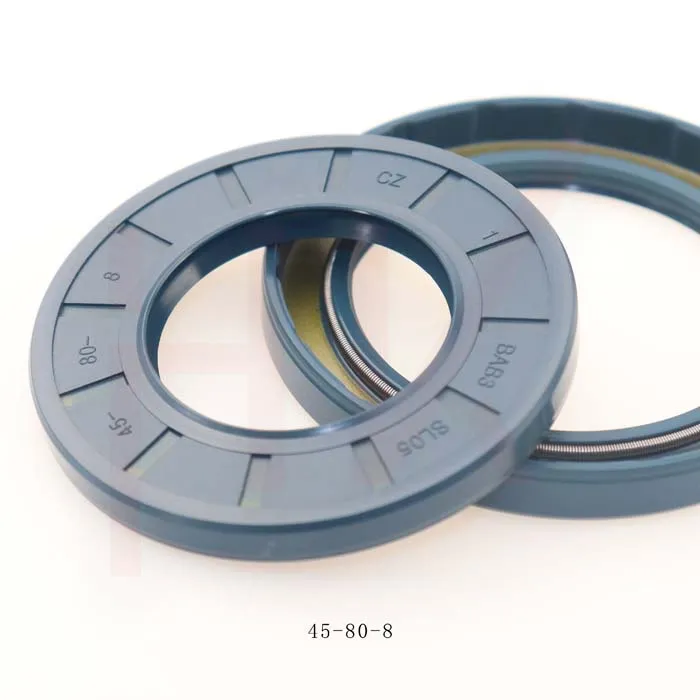

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Moreover, the ongoing research and development in seal technology underscore the authoritativeness of manufacturers who push innovation boundaries. By leveraging the latest advances in material science and design engineering, these manufacturers continue to enhance the performance and reliability of double wiper seals. They invest heavily in research, ensuring their solutions remain at the forefront of technological advancements while adapting to new challenges and applications. Customer experience is further enhanced by the flexibility offered in the installation and compatibility of double wiper seals. Designed for seamless integration into existing systems, these seals offer easy installation processes, reducing the operational disruptions typically associated with equipment maintenance. Their compatibility with a wide range of machinery components indicates a thoughtful design approach, prioritizing user-friendliness without compromising on performance. Reliable product support and an extensive network of distributors globally further reinforce the reputation of double wiper seals. Companies providing these seals prioritize an exceptional service experience, from technical assistance during installation to ongoing maintenance support. This holistic approach ensures that clients can trust in the continuous performance of their equipment, driven by robust sealing solutions. In conclusion, double wiper seals represent the confluence of experienced engineering, authoritative research, and a commitment to quality and reliability. Professionals seeking high-performance sealing solutions will find that these seals meet and often exceed the demanding standards of today’s industrial environments. By choosing double wiper seals, businesses not only optimize their operational efficiency but also invest in a product backed by years of expertise and authoritative innovation in sealing technology.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories