Oct . 06, 2025 09:15 Back to list

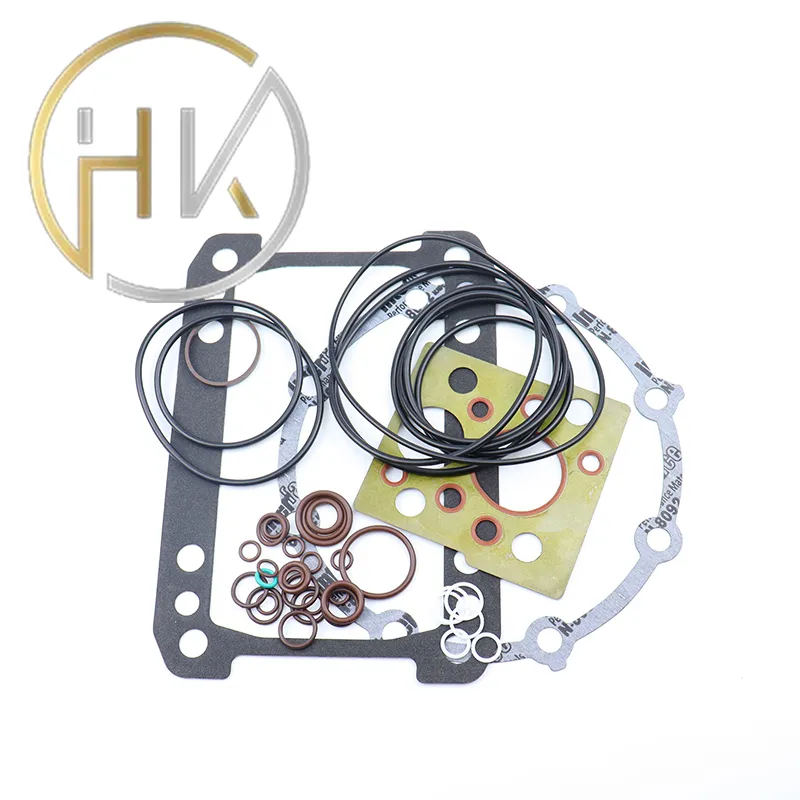

Factory direct sales hydraulic pump motor seal kit 51VO08?

Factory direct seal kits that actually last in the field

If you’re keeping critical mobile or industrial hydraulics running, you’ve probably wrestled with the real culprit behind downtime: tired seals. The Factory direct sales hydraulic pump motor seal kit 51VO08 comes straight from Hebei’s Xingtai hub—Development Zone, Julu County—where hydraulic sealing is practically a local dialect. To be honest, what caught my attention wasn’t just price; it was the consistency in compression set and the clean fit in older housings.

What’s inside the kit and why it matters

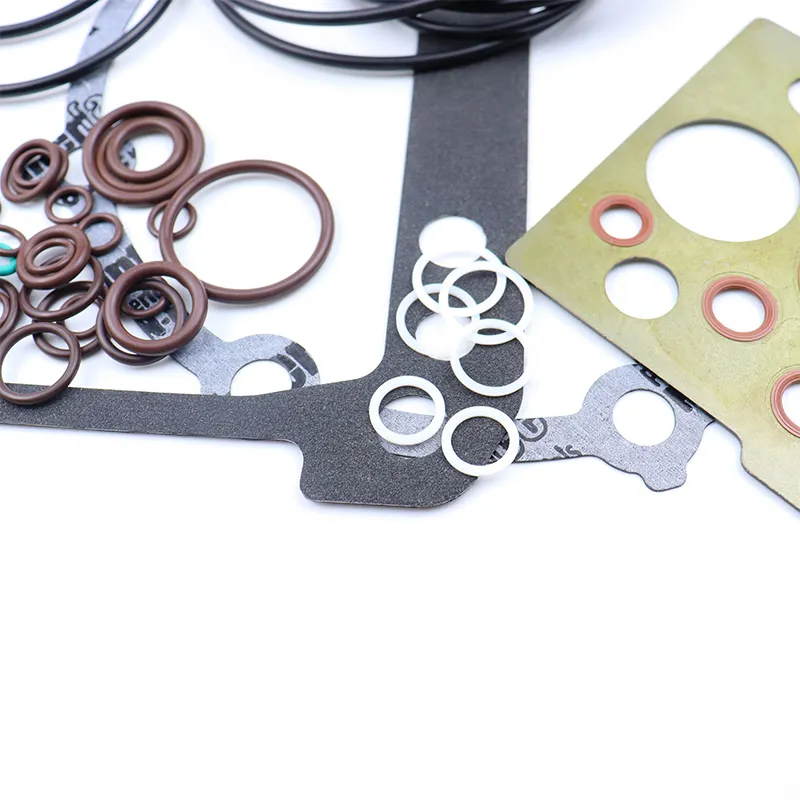

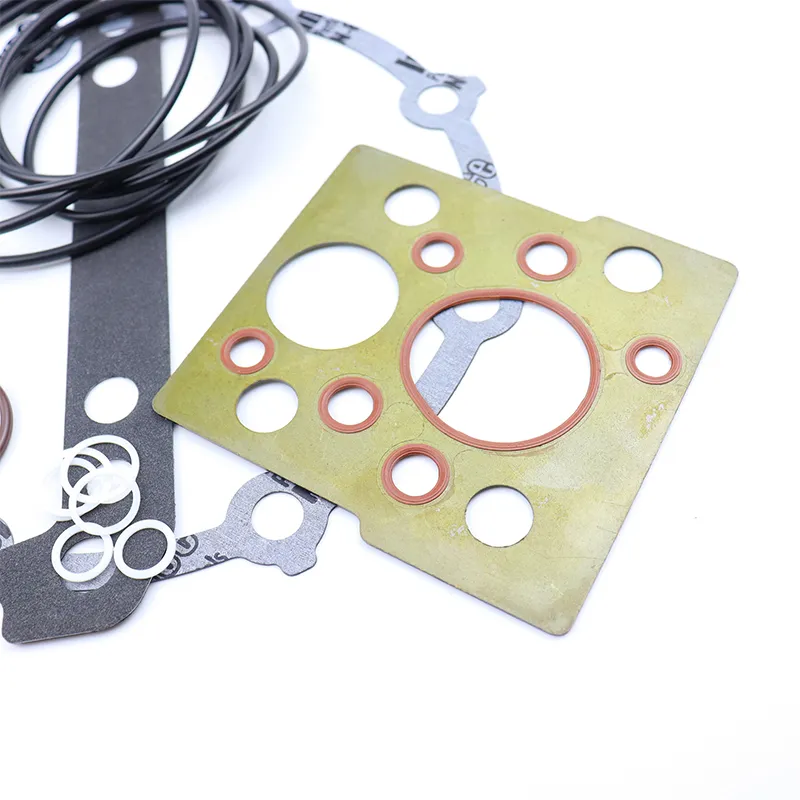

This kit targets the repair of hydraulic pumps and motors—think medium-to-high pressure units in excavators, presses, forestry skidders, and steel plant auxiliaries. In fact, many customers say the kit drops leakage rates to near-zero after proper break-in. The Factory direct sales hydraulic pump motor seal kit 51VO08 typically bundles O-rings (ISO 3601 class A), rotary lip seals (DIN/ISO equivalents), wear rings, back-up rings, and dust wipers.

Product specifications (≈ values; real-world use may vary)

| Kit Code | 51VO08 |

| Materials | NBR 70–90 Shore A, HNBR 70–90, FKM 75–90, PTFE (virgin/filled), POM wear rings |

| Fluid compatibility | Mineral oils (HL/HLP), HEES/HEPG (check swell), some bio-fluids; consult for fire-resistant fluids |

| Pressure rating | Up to 31.5 MPa typical; short peaks ≈ 35 MPa with back-up rings |

| Temperature range | NBR: −30 to +105°C; HNBR: −25 to +140°C; FKM: −15 to +200°C |

| Surface finish (mating) | Ra 0.2–0.6 μm shafts; Ra 0.4–0.8 μm bores |

| Service life | ≈3,000–8,000 h depending on duty cycle, filtration, and alignment |

Manufacturing and testing flow

- Material selection: ASTM D2000-coded compounds; batch certificates kept on file.

- Molding & cryogenic deflashing; PTFE rings CNC-machined for tolerances.

- Pre-aging/anneal to stabilize dimensions; 100% visual inspection.

- Dimensional checks to ISO 3601; lip seal runout to ISO 6194 guidance.

- Bench tests: compression set (70°C/22h), oil swell (IRM 903), pressure extrusion with back-up rings.

Where it’s used

Industries: construction machinery, injection molding, mining, steel mills, marine hydraulics, power units. Applications: pump overhauls, motor shaft rebuilds, preventive maintenance kits. Actually, the big win is reduced micro-leakage after thermal cycling.

Vendor comparison (snapshot)

| Vendor | Traceability | Lead time | Certs | Notes |

|---|---|---|---|---|

| Factory direct sales hydraulic pump motor seal kit 51VO08 | Lot-coded, material COA | 5–12 days, typical | ISO-like QA; RoHS | Best value vs. performance |

| OEM-branded kit | Full traceability | 2–6 weeks | OEM QA | Higher cost |

| Generic import | Limited | Varies | Mixed | Inconsistent sizing |

Customization and options

- Custom durometers, FKM blends for higher temp, HNBR for bio-oils.

- PTFE fillers (glass, carbon) for extrusion resistance.

- Private-label kits, laser-marked lot IDs, special packing for field techs.

Case notes from the field

A steel mill maintenance team swapped in the Factory direct sales hydraulic pump motor seal kit 51VO08 on two vane pumps. After 500 hours, they reported no visible weep, stable case pressure, and a drop in makeup oil use by ≈18%. Another contractor told me installation felt “forgiving,” especially the PTFE wear rings aligning nicely in older housings—surprisingly rare at this price point.

Compliance and good practice

Designed with ISO 4413 hydraulic safety principles in mind; O-rings sized per ISO 3601; rotary lip seals guided by ISO 6194 practices; elastomer grading to ASTM D2000. Keep filtration at β10≥200, align shafts, and avoid dry starts—yes, still the classic trio for long seal life.

Authoritative references:

- ISO 4413: Hydraulic fluid power — General rules and safety requirements.

- ISO 3601: Fluid power systems — O-rings — Dimensions and tolerances.

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications.

- ISO 6194: Rotary shaft lip-type seals — Performance and test methods.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories