Sep . 06, 2024 02:38 Back to list

High-Quality Excavator Seal Solutions for Optimal Performance

Understanding Excavator Seals Importance and Maintenance

Excavators are among the most heavily used machinery in construction and earthmoving projects, playing a crucial role in digging, trenching, lifting, and moving materials. A relatively small but vital component of these powerful machines is the seal, specifically designed to prevent fluid leaks and protect internal components from dirt, dust, and water. In this article, we will discuss the importance of excavator seals, the types available, and their maintenance.

The Importance of Excavator Seals

Excavator seals are critical for maintaining the hydraulic systems that power these machines. Hydraulic fluid must be contained within the system to ensure optimal performance and efficiency. Any leak can lead to reduced hydraulic pressure, resulting in diminished performance and potential operational failure. Besides maintaining hydraulic integrity, seals protect sensitive internal components such as cylinders and pistons from contamination, which could lead to premature wear and costly repairs.

Furthermore, seals also serve as barriers against environmental elements. Excavators often work in challenging conditions, including muddy, dusty, or wet environments. The quality and effectiveness of the seals directly impact the longevity and reliability of the machine. A well-sealed excavator is less likely to suffer from breakdowns or hydraulic failures, ensuring smoother operations on job sites.

Types of Excavator Seals

There are several types of seals used in excavators, each serving specific purposes

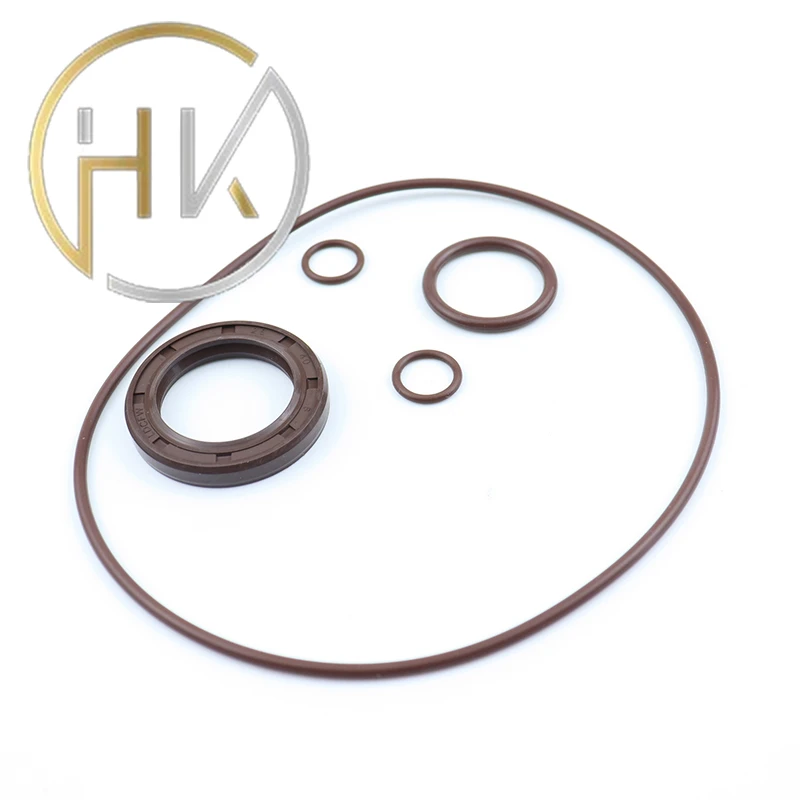

1. O-Rings This is the most common type of seal, typically made from rubber or other elastomeric materials. O-rings create a leak-proof seal between two surfaces and are used in various hydraulic fittings and connections.

2. Rod Seals Found in hydraulic cylinders, rod seals prevent leakage along the rod that extends and retracts within the cylinder. They are designed to handle dynamic movements and are crucial for maintaining cylinder pressure.

excavator seal

3. Piston Seals These seals are used in the piston area of hydraulic cylinders, ensuring that hydraulic fluid does not bypass the piston as it moves up and down.

4. Wear Rings These are installed in hydraulic cylinders to reduce friction and wear on the cylinder walls, prolonging the life of the seals and the cylinder itself.

Maintenance and Care

To ensure the longevity of excavator seals, regular maintenance is essential. Here are some best practices

- Regular Inspections Conduct routine inspections of seals and hydraulic systems for any signs of wear or damage. Check for leaks, cracks, or brittleness in seals, which may indicate the need for replacement.

- Cleanliness is Key Keep the working environment of your excavator clean. Remove dirt and debris that could compromise seal integrity. Regularly cleaning hydraulic components will help minimize wear on seals.

- Use Quality Parts When replacing seals, always opt for OEM (Original Equipment Manufacturer) parts or high-quality alternatives. Using subpar seals can lead to premature failure and increased maintenance costs.

- Monitor Operating Conditions Understand the conditions in which your excavator operates. Extreme temperatures, pressures, and contaminants can adversely affect seal performance. Whenever possible, adjust operational practices to mitigate these factors.

In conclusion, excavator seals are essential for the efficient and reliable operation of these complex machines. By understanding their importance, recognizing the different types, and committing to regular maintenance, operators can enhance their excavators' performance and longevity. Investing time and resources into seal care can ultimately lead to reduced downtime and lower overall operating costs.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories