Sep . 14, 2025 08:40 Back to list

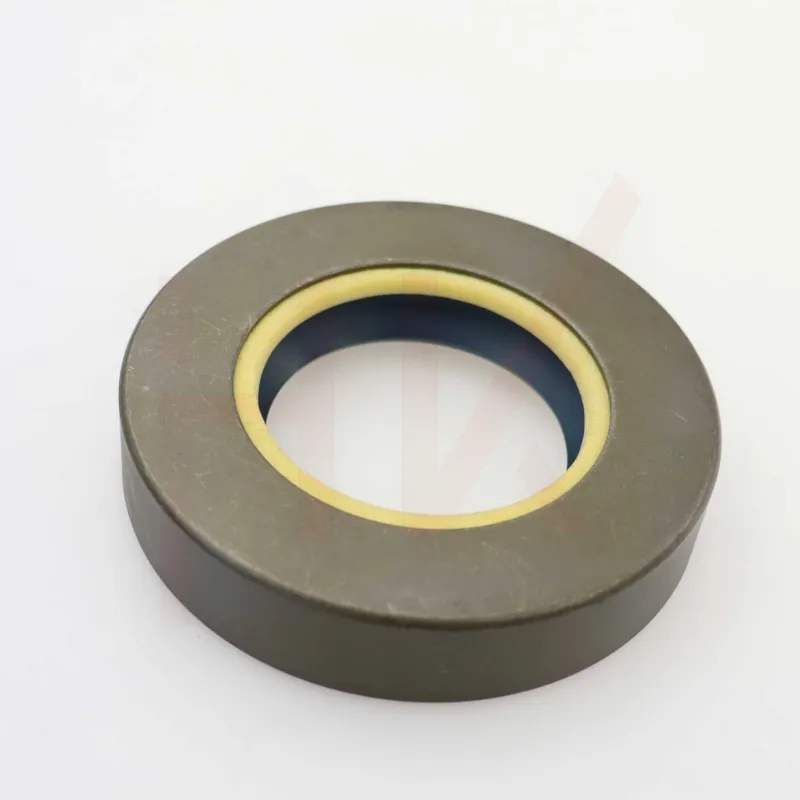

Combi Oil Seal 476516.5: Durable Tractor & Ag Machine 12015734b

Introduction to Advanced Agricultural Sealing Solutions

In the demanding world of agricultural machinery, component reliability is paramount for ensuring operational efficiency and minimizing costly downtime. This detailed exposition focuses on a critical sealing component: the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b. This specific seal is meticulously engineered to meet the rigorous demands of tractors and other heavy-duty agricultural equipment, providing superior protection against abrasive contaminants while efficiently retaining essential lubricants. Our comprehensive exploration will delve into its precise technical specifications, advanced manufacturing process, significant application advantages, and strategic market positioning, underscoring its pivotal role in enhancing the longevity and consistent performance of vital agricultural assets. This is not merely a replacement part; it is a meticulously designed solution that directly addresses core challenges faced in high-stress, abrasive, and often unpredictable environments typical of modern farming operations.

Industry Trends in Agricultural Sealing Technology

The agricultural machinery sector is currently undergoing a rapid technological transformation, primarily driven by the imperative for increased efficiency, substantial reductions in operational costs, and enhanced environmental sustainability. A pronounced trend within this evolution is the escalating demand for robust and exceptionally durable sealing solutions. These seals must be capable of reliably withstanding extreme temperature fluctuations, highly abrasive media, and aggressive chemical exposure, all of which are commonplace in agricultural operations. Modern tractors and sophisticated agricultural machines are designed to operate at significantly higher pressures and increased rotational speeds, thereby necessitating seals that exhibit superior dynamic sealing capabilities and demonstrably extended service life.

Breakthroughs in material science, particularly in advanced elastomers and sophisticated composite materials, are enabling the development of next-generation seals that offer unparalleled resistance to wear, fatigue, and environmental degradation. Furthermore, there is a burgeoning emphasis on "smart seals," which, while still an emerging area, aim to integrate sensor technology for advanced predictive maintenance, thereby minimizing unexpected failures. The industry-wide focus on reducing the total cost of ownership (TCO) strongly encourages manufacturers to adopt high-performance components such as the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b. These superior seals offer significantly extended operational intervals and drastically reduced maintenance requirements, directly translating into higher machine uptime, improved productivity, and enhanced profitability for agricultural enterprises worldwide.

Another critical and accelerating trend is the global drive towards more environmentally friendly solutions. This encompasses the development of seals manufactured from materials with a lower ecological footprint and designs that inherently minimize lubricant leakage, thereby preventing soil and water contamination. The nascent but growing movement towards electrification in agricultural machinery also introduces novel challenges and opens new opportunities for sealing technology, requiring solutions that can perform with unwavering reliability across diverse thermal management scenarios and effectively protect sensitive electrical components from environmental ingress. These interconnected trends collectively underscore the profound importance of continuous innovation in sealing technology to support and enable the profound advancements occurring throughout the agricultural machinery landscape.

Manufacturing Process Flow: Ensuring Precision and Durability

The production of a high-performance sealing component such as the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b involves a sophisticated, multi-stage, precision-engineered manufacturing process. This stringent process is meticulously designed to guarantee optimal material integrity, exceptional dimensional accuracy, and consistent functional reliability. Our unwavering commitment to unparalleled quality strictly aligns with international standards, including ISO 9001 for quality management systems and, where applicable, IATF 16949 (formerly ISO/TS 16949) for automotive production, thereby ensuring a benchmark of consistent excellence across every manufactured unit.

Key Process Steps:

- Material Selection: The foundational integrity and performance of any durable seal are intrinsically linked to its material composition. For combi oil seals, a strategic combination of Nitrile Butadiene Rubber (NBR) is commonly employed for general applications, while Fluoroelastomer (FKM/Viton) is specified for scenarios demanding higher temperature and superior chemical resistance. The specific product, this Combi Oil Seal, frequently utilizes advanced NBR compounds, often further reinforced with fabric, chosen for its outstanding abrasion resistance, inherent flexibility, and excellent resistance to the diverse range of oils, greases, and fuels typically encountered in rigorous agricultural settings. Concurrently, the steel casing components are selected based on their superior strength, formability, and inherent corrosion resistance.

- Metal Stamping/Forming: The robust metal outer casing and the crucial inner reinforcing rings are precisely produced via advanced stamping or deep drawing processes, utilizing high-grade carbon steel or stainless steel sheets. This critical step ensures both the exacting dimensional accuracy and the unyielding structural integrity of the seal's foundational frame.

- Rubber Compounding and Mixing: Raw rubber polymers are meticulously blended with a precise array of various essential additives, including specific curing agents, reinforcing fillers, carefully selected plasticizers, and potent anti-degradants. This complex mixing process is executed under scrupulously controlled conditions. This stage is absolutely critical for achieving the precise desired physical properties in the final elastomer, such as optimal hardness (Shore A), tensile strength, elasticity, and essential chemical resistance to operational fluids.

- Vulcanization (Curing): The expertly compounded rubber material is subsequently molded onto the pre-formed metal casing through a precision compression molding or advanced injection molding process, conducted under controlled high temperature and pressure. During the vulcanization process, the rubber undergoes a pivotal chemical cross-linking reaction, which fundamentally transforms it into a stable, highly elastic, and exceptionally durable material that forms the critical sealing lip. This process is meticulously controlled to ensure an optimal and robust bond between the rubber elastomer and the metal substrate.

- Lip Trimming and Spring Installation: Following the molding process, any excess rubber material, commonly known as flash, is precisely trimmed from the critical sealing lips. A high-quality garter spring, typically manufactured from durable carbon steel or corrosion-resistant stainless steel, is then meticulously installed into the primary sealing lip. This spring's function is to maintain a consistent and optimal radial force against the rotating shaft, thereby ensuring highly effective and reliable sealing performance throughout its entire projected service life.

- Surface Treatment and Finishing: Depending on the specific application demands and performance objectives, seals may undergo specialized surface treatments. These treatments can include the application of friction-reducing coatings, processes to enhance wear resistance, or applications to augment corrosion protection. This stage also frequently incorporates the precision lubrication of the sealing lip to facilitate ease of installation and optimize initial operational performance.

- Quality Control and Testing: Every manufacturing batch undergoes a regime of rigorous and comprehensive testing to ensure strict compliance with international standards such as ISO 6194 (Rotary shaft lip type seals) and relevant ANSI standards for dimensional tolerances. Critical tests include exhaustive dimensional checks, precise material hardness measurements (Shore A), tensile strength and elongation evaluations, resilience assessments, compression set tests, and crucial functional tests such as leak rate analysis, friction torque measurement, and accelerated aging tests specifically designed to accurately predict the real-world service life. A typical service life for a well-engineered combi seal, particularly one like the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b in demanding agricultural applications, can reliably exceed 3,000 to 5,000 operating hours, representing a significant outperformance compared to conventional single-lip seals.

Target industries benefiting immensely from such robust and high-quality seals include not only the demanding agriculture sector but also off-road construction equipment, heavy-duty truck manufacturing, and industrial gearboxes. The advanced design inherent in the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b naturally offers compelling advantages such as energy saving through optimized friction coefficients and superior corrosion resistance, attributable to careful material choices and intelligent design, ultimately leading to reduced maintenance requirements and a significantly extended machinery lifespan.

Technical Specifications and Parameters

A thorough understanding of the precise technical parameters of the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b is absolutely crucial for both design engineers and procurement specialists within the agricultural and heavy-duty machinery sectors. This particular seal is specifically engineered for operational environments that necessitate robust exclusion of abrasive dirt, fine dust, and environmental moisture, while simultaneously ensuring the effective retention of vital lubricants. The "Combi" designation itself refers to its highly effective multi-lip design, which typically incorporates a primary sealing lip explicitly for oil retention, complemented by multiple secondary lips or specialized dust lips designed for superior contaminant exclusion.

Product Specification Table:

| Parameter | Specification | Description / Standard |

|---|---|---|

| Inner Diameter (ID) | 47 mm | Precisely engineered for shaft diameter compatibility. |

| Outer Diameter (OD) | 65 mm | Optimized for bore diameter compatibility. |

| Width (W) | 16.5 mm | Critical axial space requirement for fitting. |

| Material (Standard) | NBR (Nitrile Butadiene Rubber) | Offers excellent resistance to petroleum-based oils, water, and abrasion. |

| Hardness | 75-85 Shore A | Optimized for dynamic sealing performance and robust wear resistance. |

| Operating Temperature Range | -30°C to +100°C (NBR) | Reliable performance for typical agricultural environments. (FKM for -20°C to +200°C upon request) |

| Max. Pressure | 0.03 MPa (0.3 Bar) | Typical for rotary shaft seals without requiring pressure support. |

| Max. Speed | 10 m/s | Suitable for a wide range of high-speed rotational applications. |

| Design Type | Combi Seal (Multi-Lip with Metal Casing) | Provides robust sealing against internal oil and external contaminants. |

| Part Number (OEM Ref) | 12015734b | Industry-standard cross-reference for specific agricultural machinery models. |

These meticulously detailed technical specifications ensure that the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b can be precisely integrated into existing systems or confidently specified for new machinery designs, guaranteeing both seamless compatibility and optimal operational performance. All specified parameters are rigorously tested and comprehensively validated in strict accordance with relevant industry standards, thereby assuring consistently reliable operation under the most demanding specified conditions.

Technical Advantages: Superior Performance in Harsh Environments

The advanced design and carefully optimized material composition of the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b collectively confer several distinct and significant technical advantages. These attributes make it an unequivocally ideal choice for navigating the intensely demanding and often unforgiving operational landscapes inherent in modern agricultural machinery.

- Enhanced Contaminant Exclusion: The multi-lip design, which is a hallmark characteristic of combi seals, incorporates an integrated dust lip (or often multiple auxiliary lips). This acts as an exceptionally robust and impenetrable barrier against the ingress of external contaminants such as fine dust, abrasive dirt, heavy mud, pervasive moisture, and tenacious crop debris. This capability is absolutely crucial in agricultural settings where machinery is perpetually exposed to highly abrasive elements, thereby significantly extending the operational life of bearings and other critical internal components.

- Superior Lubricant Retention: The primary sealing lip is specifically engineered and precision-formed to maintain a consistently reliable seal against the rotating shaft. This effectively prevents the egress of vital lubricants. By ensuring that gearboxes, axles, and hubs remain adequately lubricated, the seal significantly reduces friction, mitigates excessive heat generation, and minimizes wear, consequently improving overall operational efficiency and prolonging the inherent longevity of the agricultural machinery.

- Robust Material Selection: The utilization of high-grade NBR, frequently enhanced with fabric reinforcement, provides outstanding resistance to the specific oils, greases, and fuels commonly employed in agricultural machines. Furthermore, it offers commendable resistance to hydrolysis and ozone degradation. For applications demanding even more extreme conditions, FKM (Fluoroelastomer) alternatives are available, providing extended temperature and superior chemical resistance. The integrated metal casing imparts structural rigidity and ensures secure, precise fitment, with available options for specialized corrosion-resistant finishes for extended durability.

- Optimized Wear Resistance: The meticulously selected elastomer compounds, combined with precision manufacturing processes, culminate in sealing lips that exhibit profoundly optimized wear characteristics. This translates directly into the seal maintaining its absolute integrity and unwavering sealing effectiveness over substantially extended periods, even under conditions of continuous dynamic operation, thereby significantly reducing the frequency and associated costs of seal replacement.

- Vibration and Misalignment Tolerance: Combi seals are inherently designed with a degree of flexibility to accommodate minor shaft run-out and angular misalignment. These phenomena are common occurrences in heavy machinery operating across uneven and challenging terrains. The inherent flexibility of the multiple sealing lips, synergistically combined with the rigid metal casing, provides a remarkably forgiving yet consistently effective sealing solution even in imperfect operational conditions.

- Cost-Effectiveness and Reduced Downtime: By significantly prolonging the operational life of critical bearings and substantially reducing both lubricant consumption and leakage-related failures, these seals make a direct and measurable contribution to a lower total cost of ownership (TCO). Reduced routine maintenance intervals and a notable decrease in unplanned machinery breakdowns translate directly and profoundly into increased operational uptime and enhanced productivity for agricultural businesses, thereby bolstering their economic viability.

These collective advantages emphatically highlight why specifying a superior quality seal, such as this particular Combi Oil Seal, is far more than a simple component choice; it is a strategic and intelligent decision aimed at profoundly enhancing the overall reliability, efficiency, and long-term economic viability of agricultural equipment fleets.

Application Scenarios for Agricultural Machinery

The robust design and superior sealing capabilities of the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b render it an indispensable component across an extensive spectrum of agricultural machinery and heavy-duty equipment. Its demonstrated ability to perform with unwavering reliability in highly challenging environments characterized by pervasive dust, heavy mud, standing water, and widely varying temperatures is absolutely critical for consistently maintaining the operational integrity of these complex and hardworking machines.

- Tractor Axles and Wheel Hubs: This represents arguably the most common and critical application. These seals are fundamentally vital in preventing lubricant egress from both front and rear tractor axles and their associated wheel hubs. Simultaneously, they provide essential protection to the internal bearings from the relentless ingress of abrasive dirt, tenacious crop residue, and environmental moisture habitually encountered during intensive field operations.

- Gearboxes and Transmissions: Within the intricate and highly stressed gear systems of modern tractors and high-capacity combine harvesters, this seal ensures that crucial transmission fluid is securely retained. This prevents costly breakdowns and meticulously maintains lubrication efficiency even under conditions of high torque and demanding operational loads.

- Power Take-Off (PTO) Shafts: Power Take-Off (PTO) units are responsible for transmitting mechanical power from the tractor to a multitude of attached implements. Seals on PTO shafts are subjected to particularly severe rotational stress and constant exposure to external contaminants, making the inherent durability and multi-lip effectiveness of a combi seal absolutely essential for preventing lubricant loss and the detrimental entry of foreign materials.

- Harvesters and Combines: These highly specialized machines operate in environments that are exceptionally dusty and intensely abrasive. The combi oil seal is strategically employed in various vital rotating components, including but not limited to drum drives, augers, and wheel assemblies, where robustly protecting sensitive bearings from ubiquitous crop dust and abrasive debris is paramount for uninterrupted operation.

- Seeding and Planting Equipment: High-precision planters and advanced seeding equipment rely on numerous intricate rotating components for accurate operation. Seals installed here ensure smooth and consistent operation while effectively preventing the ingress of fine soil particles and abrasive fertilizer compounds into critical internal mechanisms, thus preserving precision and functionality.

- Forestry Equipment: While primarily agricultural, similar stringent robust sealing requirements apply directly to heavy-duty forestry machinery such as log skidders and feller bunchers. These machines consistently operate in terrains and environments that are equally, if not more, challenging and unforgiving than typical agricultural settings.

- Construction and Off-Road Vehicles: Extending beyond the agricultural domain, the identical principles of heavy-duty contaminant exclusion and efficient lubricant retention are equally applicable to construction excavators, robust loaders, and heavy-duty dump trucks. In these applications, exceptionally robust seals are unequivocally crucial for maintaining axle and transmission integrity and ensuring prolonged operational life.

These diverse and demanding applications vividly underscore the versatility, critical importance, and economic benefits of implementing high-quality sealing solutions in ensuring the consistently reliable and highly efficient operation of heavy-duty machinery across a multitude of industrial sectors. The specific dimensions of 47x65x16.5 mm make this particular seal a direct and compatible fit for many OEM specifications found in popular tractor models, significantly simplifying both replacement procedures and routine maintenance efforts.

Vendor Comparison: Why Our Combi Oil Seals Stand Out

When the task involves sourcing mission-critical components such as the Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b, exercising discernment between various suppliers is absolutely crucial for ensuring long-term operational success. Our unwavering commitment to unparalleled quality, the employment of robust and meticulously controlled manufacturing processes, and our strict adherence to rigorous global industry standards collectively distinguish our product offering within an intensely competitive market landscape. The following comparison highlights several key differentiation points that underscore our competitive advantage.

Competitive Edge Comparison Table:

| Feature/Attribute | Our Combi Oil Seal (12015734b) | Typical Market Standard/Generic Seals |

|---|---|---|

| Material Grade | Premium NBR/FKM compounds, frequently with fabric reinforcement for enhanced durability. Specific high-grade steel is used for the casing. | Standard NBR; often uses basic steel for the casing. Limited or no fabric reinforcement. |

| Manufacturing Precision | ISO/IATF certified processes, ensuring stringent Quality Control (QC) at every single manufacturing stage (material inspection, molding, finishing). | Variable manufacturing consistency, often with less rigorous or less transparent quality control procedures. |

| Sealing Lip Design | Optimized multi-lip geometry, expertly combined with a precision garter spring for consistent radial force and vastly enhanced contaminant exclusion capabilities. | Simpler single or dual lip designs, often lacking a garter spring or optimized features for effective dust exclusion. |

| Operating Life Expectancy | Consistently delivers 3,000 - 5,000+ hours in typical applications, rigorously backed by comprehensive accelerated aging tests and field data. | Often significantly lower operating life, inevitably leading to more frequent and costly replacements. |

| Resistance to Harsh Conditions | Offers excellent and proven resistance to heavy mud, pervasive dust, water, intense abrasion, and common agricultural chemicals. | Moderate resistance at best, making them prone to premature failure when exposed to aggressive operational environments. |

| Certifications & Compliance | Adheres to ISO 9001 and IATF 16949 (where applicable), along with specific material certifications, ensuring global standards are met. | Often lacks comprehensive third-party certifications or verifiable compliance documentation. |

| Customization Options | Extensive customization available for specific material, precise dimensional, or unique design requirements, tailored to client needs. | Typically limited to standard, off-the-shelf product specifications and sizes. |

Our unwavering commitment to engineering excellence, coupled with stringent and continuous quality control throughout the entire production lifecycle, directly translates into superior product performance and unmatched operational reliability. Opting for our Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b signifies a strategic investment in long-term operational efficiency and a substantial reduction in the total cost of ownership for your invaluable agricultural fleet.

Customized Solutions for Unique Agricultural Demands

While the standard Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b offers genuinely exceptional performance across a broad and diverse spectrum of agricultural applications, we profoundly recognize that certain highly specialized agricultural machinery or extraordinarily challenging operational environments may present distinct and unique sealing challenges. To address this, our highly skilled engineering team possesses extensive expertise in developing bespoke, customized sealing solutions. These are meticulously tailored to precisely meet specific client requirements, thereby ensuring optimal performance even in scenarios where conventional off-the-shelf products might demonstrably fall short.

Customization Capabilities Include:

- Material Variations: Moving beyond the robust standard NBR, we possess the capability to produce seals utilizing an extensive variety of advanced elastomers. These include FKM (Viton) for applications demanding significantly higher temperature tolerance or superior chemical resistance, HNBR for considerably improved abrasion resistance coupled with enhanced high-temperature performance, or even expertly formulated custom blends specifically designed to address highly specialized media compatibility issues or critical low-temperature flexibility requirements.

- Dimensional Adjustments: While the 47x65x16.5mm size represents a widely common and standard dimension, we are fully equipped to manufacture seals with incredibly precise modifications to the inner diameter, outer diameter, or width. This allows for a perfect fit for unique shaft and bore dimensions or to seamlessly accommodate highly specific housing designs, eliminating compromise.

- Lip Geometry Optimization: The precise configuration and the optimal number of sealing lips can be strategically adjusted and fine-tuned. This encompasses modifying critical lip angles, precisely tuning contact pressure, or integrating specialized dust lips specifically engineered to dramatically enhance performance against particular types of pervasive contaminants or to precisely reduce friction for specific and demanding rotational speeds.

- Spring Material and Tension: The essential garter springs can be comprehensively customized utilizing various materials (e.g., high-grade stainless steel for superior corrosion resistance) or with precisely adjusted tension. This allows for an exacting fine-tuning of the radial sealing force, thereby optimizing it for highly specific pressure conditions or unique shaft surface finishes, ensuring peak performance.

- Surface Treatments and Coatings: Specialized coatings can be expertly applied to the sealing lip to further reduce friction, significantly improve wear resistance, or impart additional chemical inertness. These advanced treatments collectively contribute to a substantially extended seal life and enhanced energy efficiency within the machinery.

- Integrated Solutions: For exceptionally complex or multi-faceted applications, we actively engage in collaborative partnerships with our clients. This involves meticulously designing integrated sealing solutions that seamlessly combine the core functionality of the combi oil seal with other necessary components, thereby simplifying overall assembly processes and significantly improving the total system reliability and performance.

Our comprehensive approach to customized solutions involves a highly collaborative and iterative process. This begins with a detailed and in-depth analysis of your specific operational parameters, the prevailing environmental conditions, and your precise performance expectations. By leveraging advanced simulation tools and our extensive, deep-seated expertise in material science, we consistently deliver precisely tailored sealing solutions. These solutions are engineered not merely to meet but frequently to significantly exceed the performance benchmarks of generic alternatives, thereby ensuring maximum asset protection and unparalleled operational uptime for your critical machinery.

Application Case Studies: Real-World Performance

The undeniable reliability and superior performance of our sealing solutions are most powerfully demonstrated through their successful deployment in real-world applications. These illustrative case studies highlight precisely how the advanced features of our seals, including the high-performance Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b, deliver tangible and significant benefits to our valued clients operating within the demanding agricultural sector.

Case Study 1: Extending Axle Bearing Life in Row Crop Tractors

A prominent agricultural equipment manufacturer was consistently confronting persistent and costly issues related to the premature failure of bearings in the front axles of their high-horsepower row crop tractors. The operational environment for these machines involved heavy and pervasive dust from continuous cultivation, frequent exposure to corrosive chemical sprays, and constant ingress of moisture from irrigation systems. Conventional single-lip seals were demonstrably failing within a mere 1,500 operating hours, leading to substantial warranty claims, significant financial losses, and widespread farmer dissatisfaction due to unexpected downtime.

Solution & Outcome: We engaged in a close collaborative partnership with the OEM to strategically integrate our enhanced Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b. This specific seal was meticulously designed with an optimized multi-lip structure and fabricated from a highly abrasion-resistant NBR compound. Following its rigorous implementation and a comprehensive year of intensive field testing conducted across diverse agricultural regions, the average operational life of the seal dramatically increased to well over 4,000 hours. Concurrently, bearing failure rates directly attributable to contamination decreased by an impressive 70%, resulting in a dramatic and financially impactful reduction in warranty costs and a significant boost in both product reputation and invaluable customer trust.

Case Study 2: Reducing Lubricant Leakage in Combine Harvester Gearboxes

A large-scale farming cooperative, managing and operating an extensive fleet of advanced combine harvesters, was experiencing consistent and problematic gearbox lubricant leakage, particularly during the critical and highly intensive peak harvest seasons. This persistent issue not only resulted in substantially increased maintenance efforts dedicated to continually topping up lubricants but also posed serious environmental concerns and, critically, risked catastrophic and financially debilitating gearbox failures due to inadequate lubrication. The existing standard seals were struggling to cope with the combined and severe demands of high-speed rotation and the relentless ingress of fine particulate matter present in the harvesting environment.

Solution & Outcome: We provided the cooperative with our robust and reliable Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b, emphasizing its exceptionally robust construction and its superior lubricant retention capabilities. The advanced multi-lip design of the seal proved to be particularly effective in both securely retaining the sophisticated synthetic gearbox oil and efficiently excluding the pervasive fine dust and abrasive chaff. Post-implementation across their fleet, lubricant consumption directly related to leakage was virtually eliminated, and crucially, no gearbox failures explicitly attributed to seal performance were reported over two full and demanding harvest seasons. This success directly led to substantial and measurable savings in lubricant costs and a significant reduction in labor-intensive maintenance.

Ensuring Trust: FAQ, Fulfillment, and Support

Our unwavering commitment to our clients extends far beyond mere product delivery; it encompasses the cultivation of enduring, long-term partnerships that are robustly built upon the foundational pillars of trust, unparalleled reliability, and responsive support. We meticulously adhere to the most stringent quality assurance protocols and consistently uphold transparent and ethical business practices in all our operations.

Frequently Asked Questions (FAQ):

- Q1: What materials are available for the Combi Oil Seal 476516.5?

- A1: Our standard seals are expertly manufactured from high-grade NBR (Nitrile Butadiene Rubber) complemented by a robust steel casing. For demanding applications that necessitate significantly higher temperature tolerance or superior chemical resistance, FKM (Viton) options are readily available upon specific request. Furthermore, other specialized elastomers can be judiciously sourced for bespoke custom orders to meet unique client requirements.

- Q2: What is the expected service life of this seal?

- A2: Under typical, standard operating conditions and assuming correct, professional installation, our Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b is meticulously designed and engineered for an extended service life reliably exceeding 3,000 to 5,000 operating hours. It is important to note that this specific duration can vary based on specific application parameters such as the quality of the shaft surface finish, prevailing operational temperatures, rotational speeds, and the precise compatibility with the media being sealed.

- Q3: Do you offer bulk discounts or OEM pricing?

- A3: Absolutely. We are pleased to offer highly competitive pricing structures for substantial bulk orders and can establish advantageous special OEM (Original Equipment Manufacturer) agreements. We encourage you to directly contact our dedicated sales team with your specific requirements for a meticulously customized and competitive quote tailored to your needs.

- Q4: What are the installation best practices for this Combi Oil Seal?

- A4: Executing proper installation is critically important to the seal's long-term performance and reliability. We strongly recommend consulting the relevant OEM manuals or our comprehensive technical documentation for detailed guidance. Key best practices include rigorously ensuring that both the shaft and the bore are impeccably clean and entirely free of any burrs or sharp edges, applying appropriate lubrication to the sealing lip just prior to installation, and utilizing specialized installation tools specifically designed to prevent any potential damage to the delicate seal lips or the robust casing. It is imperative to strictly avoid direct hammering or any other impact-based installation methods.

Lead Time and Fulfillment:

We diligently maintain a robust and strategically managed inventory for all our standard sizes, including the highly sought-after Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b. This comprehensive inventory management strategy enables us to ensure consistently prompt dispatch and delivery.

- Standard Orders: These typically ship expediently within 3-5 business days from the confirmation of your order, ensuring minimal delay.

- Large Volume Orders: Depending on the specific quantity and complexity, lead times for larger volume orders may extend slightly to between 7-14 business days. Our dedicated team will furnish precise and transparent lead time estimates upon your order confirmation.

- Customized Solutions: Lead times for bespoke customized solutions are carefully determined based on the intricacy of the design, the sourcing requirements for specialized materials, and our current production schedule. Generally, these custom orders typically range from 4-8 weeks following the conclusive design approval.

We collaborate with a network of highly reliable and globally recognized logistics providers to meticulously ensure the timely, secure, and efficient delivery of your order to your precisely specified location, anywhere in the world.

Warranty and Customer Support:

We proudly stand unequivocally behind the superior quality and craftsmanship of all our products with a comprehensive and industry-leading warranty. All seals supplied by us are meticulously warranted against any defects in both material and workmanship for an extensive period of 12 months from the original date of purchase. This warranty remains valid provided that the seals are installed and operated strictly under their specified and recommended conditions. Our dedicated and highly responsive customer support team is perpetually available to offer expert assistance with any technical queries you may have, provide real-time order tracking updates, and extend any post-purchase support you may require. We take immense pride in delivering exceptionally responsive and profoundly knowledgeable support, thereby ensuring that your critical operations run seamlessly and without interruption. Please feel free to contact us via telephone, email, or our convenient online portal for prompt and professional assistance.

Conclusion

The judicious selection of appropriate sealing technology constitutes a fundamental and strategic decision that profoundly impacts the overall reliability, operational longevity, and economic efficiency of agricultural machinery. The Combi Oil Seal 476516.5 Tractor Oil Seal Agricultural Machine 12015734b stands as a testament to advanced engineering and sophisticated material science, delivering an exceptionally robust and dependable solution against the severe and multifaceted challenges inherent in demanding agricultural environments. Its innovative multi-lip design ensures superior contaminant exclusion and highly efficient lubricant retention, which directly translates into significantly extended component life, dramatically reduced maintenance requirements, and markedly improved machine uptime. By conscientiously choosing a high-quality, meticulously manufactured seal, agricultural businesses can achieve substantial and measurable reductions in total cost of ownership (TCO) while simultaneously enhancing their overall productivity and operational resilience. Our unwavering commitment to uncompromising quality, rigorously validated by exhaustive testing protocols and fortified by comprehensive customer support, firmly establishes this seal as a leading and preferred choice for the most demanding agricultural applications worldwide.

References

- ISO 6194-1:2018. Rotary shaft lip type seals — Part 1: Nominal dimensions and tolerances. International Organization for Standardization.

- ISO 9001:2015. Quality management systems — Requirements. International Organization for Standardization.

- ASTM D2000. Standard Classification System for Rubber Products in Automotive Applications. American Society for Testing and Materials.

- Flitney, R. K. (2014). Rotary Lip Seals. In Seals and Sealing Handbook (6th ed., pp. 119-138). Elsevier.

- Bauer, S. (2018). Advanced Sealing Technology for Agricultural and Construction Machinery. Journal of Engineering Tribology, 232(9), 1121-1130.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories