Sep . 15, 2024 21:55 Back to list

cfw oil seal

Understanding CFW Oil Seals Essential for Machinery Efficiency

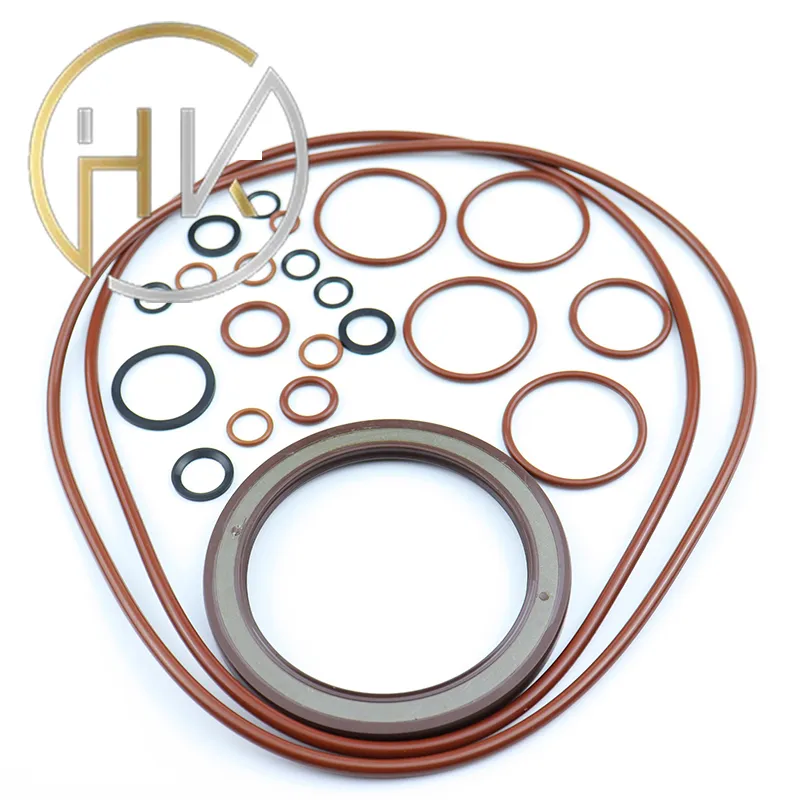

Oil seals, commonly referred to as oil rings or hydraulic seals, are crucial components in various machinery and automotive applications. Among the various types of oil seals available, CFW (Concentric Face Wiper) oil seals have garnered attention for their unique design and effectiveness. Understanding their structure, functionality, and applications can significantly enhance machinery performance and longevity.

What is a CFW Oil Seal?

A CFW oil seal is designed to prevent the leakage of lubricants while keeping contaminants out of machinery. The “CFW” designation typically refers to the concentric face design, which features a flexible lip that forms a dynamic seal against a rotating shaft. This design allows the seal to adapt to slight variations in shaft positioning and alignment, ensuring consistent performance over time.

Key Features of CFW Oil Seals

1. Material Composition CFW oil seals are often made from durable materials such as rubber, polyurethane, or synthetic compounds. This selection is vital as it influences the seal’s resistance to oil, temperature, and wear, which are critical in maintaining optimal performance.

2. Design Structure The concentric face design enhances the sealing capability by distributing pressure evenly. This not only reduces wear on the seal but also extends its lifespan. The flexibility of the lip ensures that it maintains contact with the shaft, thus preventing leaks effectively.

cfw oil seal

3. Versatility CFW oil seals can be used in various applications, ranging from automotive engines to industrial machinery. Their ability to perform under diverse operational conditions makes them a popular choice in sectors like manufacturing, automotive, and aerospace.

Benefits of Using CFW Oil Seals

- Leak Prevention One of the primary functions of CFW oil seals is to prevent oil leakage. This is crucial for maintaining the efficiency of machinery and preventing costly damage that can arise from lubricants escaping the system.

- Contaminant Exclusion In addition to preventing oil loss, these seals effectively block dust, dirt, and other contaminants from entering the machinery. This protection is essential for preserving the internal components and ensuring they function efficiently.

- Reduced Maintenance Costs With reliable sealing capabilities, CFW oil seals contribute to lower maintenance costs. Machinery equipped with high-quality seals experiences fewer breakdowns and repairs, leading to increased uptime and productivity.

Conclusion

In summary, CFW oil seals play an essential role in maintaining the efficiency and longevity of machinery. Their unique design and high-quality materials make them ideal for various applications across multiple industries. Understanding the significance and benefits of these seals can aid in selecting the right components for machinery, ultimately leading to better performance and reduced operational costs. Investing in quality CFW oil seals is not merely a maintenance decision; it's a strategic move towards ensuring the longevity and reliability of your equipment. As technology continues to evolve, the role of efficient sealing solutions like CFW oil seals will undoubtedly remain a cornerstone in the realm of machinery management.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories