Sep . 22, 2025 13:30 Back to list

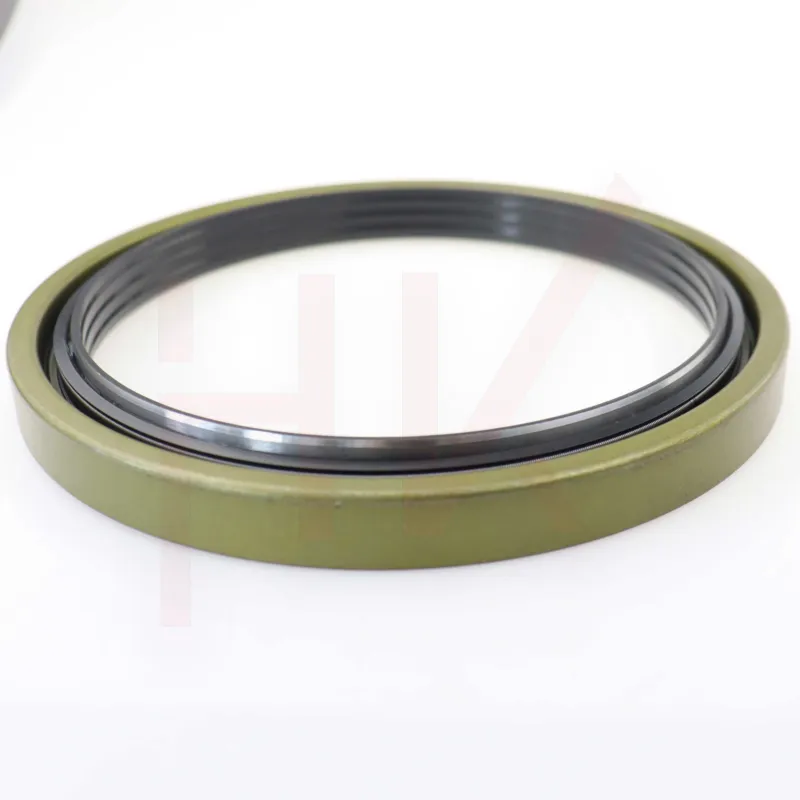

AL154055 AL81842 Tractor Hub Oil Seal | Precision 167.819815.5

Industry Trends in Agricultural Machinery Sealing Technology

The agricultural sector is undergoing a significant transformation, driven by demands for increased efficiency, sustainability, and reduced operational costs. This evolution directly impacts the design and performance requirements of critical components such as oil seals. Modern tractors and heavy agricultural equipment operate under increasingly severe conditions, necessitating sealing solutions that offer unparalleled durability, resistance to aggressive media, and extended service life. Key trends include the adoption of advanced elastomeric materials, sophisticated lip designs, and integrated sealing systems to combat abrasive environments, extreme temperatures, and higher shaft speeds.

There's a growing emphasis on minimizing friction and power loss, directly contributing to fuel efficiency and reduced carbon footprints. This drives innovation in low-friction sealing solutions, often involving optimized lip geometries and specialized coatings. Furthermore, the integration of smart technologies in agricultural machinery demands seals capable of maintaining integrity in complex mechatronic systems, where sensor integration and precision lubrication are paramount. Reliability and maintainability are also key considerations, with seals expected to perform flawlessly for thousands of operating hours, reducing downtime and maintenance overheads for agricultural enterprises.

For instance, the demand for 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors is indicative of this trend, where specific dimensions and robust performance are crucial for heavy-duty applications in the agricultural domain.

Detailed Manufacturing Process Flow

The production of a high-performance hub oil seal like the 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors involves a meticulously controlled multi-stage process, ensuring precision, durability, and consistent quality. This process leverages advanced material science and engineering techniques to meet stringent industry standards.

1. Material Selection & Compounding

Selection of high-grade elastomers (e.g., NBR, FKM for temperature/chemical resistance, HNBR for superior abrasion). Precision compounding with additives (carbon black, vulcanizing agents) for optimal mechanical properties. Conformance to ASTM D2000 specifications.

2. Steel Insert Stamping/Forming

Precision stamping or deep drawing of cold-rolled steel (e.g., DIN EN 10130 DC01) for the reinforcing case, ensuring exact dimensions (e.g., 198mm OD) and concentricity. This forms the rigid backbone of the seal.

3. Rubber Molding & Vulcanization

The elastomer compound is compression or injection molded around the steel insert. High-pressure and controlled temperature during vulcanization (curing) cross-links the polymer chains, defining the seal's final shape, lip geometry, and material hardness (e.g., 70-85 Shore A).

4. Spring Insertion & Trimming

A garter spring, typically made of spring steel (e.g., AISI 302/304 stainless steel), is precisely inserted into the primary sealing lip to maintain consistent radial force against the shaft. Excess flash from molding is meticulously trimmed.

5. Post-Curing (if applicable)

For certain materials like FKM, a post-curing process at elevated temperatures further enhances physical properties, improves compression set, and eliminates volatile byproducts, crucial for long-term performance.

6. Quality Control & Testing

Each batch undergoes rigorous testing: dimensional inspection (ISO 3601), material hardness (ASTM D2240), tensile strength (ASTM D412), compression set (ASTM D395), and often dynamic shaft testing for leakage and friction. Adherence to ISO 9001 quality management systems is paramount.

Target industries for seals manufactured with such precision include petrochemical, metallurgy, automotive, and particularly agriculture. In typical application scenarios for tractors, advantages include enhanced energy saving due to optimized lip designs reducing friction, superior corrosion resistance from appropriate material selection, and extended service life due to robust manufacturing and quality control, even in abrasive environments.

Technical Specifications and Parameters

The 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors is engineered to meet the rigorous demands of heavy-duty agricultural machinery. Its design incorporates specific dimensions and material properties to ensure optimal sealing performance under challenging operational conditions. Understanding these technical parameters is crucial for ensuring compatibility and maximizing component longevity.

Key Product Specifications

| Parameter | Value/Description |

|---|---|

| Product Name | 01027784B/AL154055 AL81842 Hub Oil Seal |

| Inner Diameter (ID) | 167.8 mm |

| Outer Diameter (OD) | 198 mm |

| Width/Height (H) | 15.5 / 16 mm (nominal) |

| Material (Sealing Lip) | NBR (Nitrile Butadiene Rubber) - Standard, FKM (Fluoroelastomer) - Optional for higher temps/chemicals |

| Material (Metal Case) | Carbon Steel (e.g., DIN EN 10130 DC01) with corrosion-resistant coating |

| Material (Garter Spring) | Spring Steel (AISI 302/304 Stainless Steel for enhanced corrosion resistance) |

| Operating Temperature Range (NBR) | -30°C to +100°C (Short term up to +120°C) |

| Operating Temperature Range (FKM) | -20°C to +200°C (Short term up to +220°C) |

| Max. Pressure Differential | 0.5 bar (standard for rotary shaft seals; higher for specialized designs) |

| Max. Peripheral Speed | Up to 10 m/s (material and shaft finish dependent) |

| Hardness (Shore A) | 70-85 Shore A |

| Typical Service Life | >3000 operating hours (under recommended conditions) |

| Standards Compliance | ISO 3601, DIN 3760, ASTM D2000, ISO 9001 (manufacturing) |

These specifications underscore the robust engineering behind this seal, designed to withstand the harsh conditions prevalent in agricultural machinery. The choice between NBR and FKM largely depends on the specific tractor model's operating environment, especially concerning lubricant types and ambient temperatures.

Application Scenarios and Technical Advantages

The reliability of agricultural machinery hinges on the integrity of its sealing components. The 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors excels in a range of demanding applications, providing critical protection against contaminants while retaining vital lubricants.

Key Application Scenarios:

- Tractor Wheel Hubs: Essential for preventing the ingress of dust, mud, water, and debris into wheel bearings, while simultaneously retaining lubricating oil or grease. This directly impacts bearing lifespan and operational safety.

- Agricultural Implement Gearboxes: Providing robust sealing for the output shafts of gearboxes found in cultivators, harvesters, and balers, which often operate in dusty, vibrating environments.

- Power Take-Off (PTO) Units: Sealing critical interfaces on PTO shafts, preventing lubricant leakage and external contamination, crucial for efficient power transfer to implements.

- Axle Assemblies: Integral to maintaining the sealed integrity of tractor axles, safeguarding differential and final drive lubricants from environmental factors.

Technical Advantages:

- Superior Contaminant Exclusion: Multi-lip designs, often incorporating a primary sealing lip and auxiliary dust lips, effectively prevent the ingress of abrasive particles (e.g., soil, sand, crop residue), extending bearing and component life. This is vital in agricultural settings.

- Robust Chemical Compatibility: With material options like NBR for standard hydraulic fluids and FKM for more aggressive synthetic lubricants or higher temperatures, the seal ensures integrity against a wide array of agricultural chemicals and oils, preventing material degradation and premature failure.

- High Temperature & Pressure Resistance: Designed to maintain sealing force and material properties across a broad temperature range, and capable of withstanding moderate pressure differentials often encountered in heavy machinery hubs without extrusion or leakage.

- Optimized Friction & Wear Characteristics: Precision-engineered lip geometries minimize friction and heat generation, reducing power consumption and extending the service life of both the seal and the mating shaft. Advanced elastomers offer excellent wear resistance, even with minor shaft imperfections.

- Enhanced Dynamic Sealing: The garter spring ensures consistent radial load on the shaft, maintaining an effective seal even during shaft eccentricity, misalignment, and vibrations common in tractor operations. This dynamic capability is critical for preventing leaks under varying load conditions.

Vendor Comparison: Why Choose Our Hub Oil Seals

In a competitive market for precision sealing solutions, selecting the right vendor for components like the 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors is paramount. Our commitment to quality, innovation, and customer-centric service distinguishes us from general suppliers. Here's a comparison highlighting our strengths:

Comparative Analysis

| Feature | Our Offering | Typical Competitor |

|---|---|---|

| Material Quality & Sourcing | Premium, traceable virgin elastomers (e.g., European/US NBR, FKM). Batch tested to ASTM D2000. | Standard industrial grade, potentially mixed batches, less stringent testing. |

| Manufacturing Precision | ISO 9001 certified facilities, advanced CNC molding, automated inspection for dimensional accuracy (ISO 3601). | Variable quality control, manual processes, higher tolerance stack-up. |

| Design & Engineering Support | Expert engineering team offering design optimization, custom solutions, finite element analysis (FEA) for complex applications. | Limited technical support, off-the-shelf solutions only. |

| Performance & Service Life | Extended operational lifespan (>3000 hours typical), superior resistance to wear, temperature, and media. Proven field performance. | Shorter average service life, higher risk of premature failure under stress. |

| Cost-Efficiency (Total Ownership) | Higher initial investment, but significantly reduced total cost of ownership through less downtime, lower maintenance, and extended component life. | Lower initial cost, but higher total cost due to frequent replacements, potential equipment damage, and increased labor. |

| Certifications & Compliance | ISO 9001, Material batch certifications, RoHS compliant. | Basic or no certifications, inconsistent compliance. |

Our dedication to engineering excellence and stringent quality control ensures that our seals deliver unmatched performance and reliability, ultimately safeguarding your investment in heavy agricultural machinery. We have been serving the industry for over 15 years, building trust with major OEM clients and aftermarket distributors globally.

Customized Solutions for Specific Needs

While our standard 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors offers exceptional performance across a broad range of applications, we understand that specific operational environments can demand unique sealing characteristics. Our engineering team specializes in developing customized sealing solutions tailored to precise customer requirements.

Our Customization Capabilities Include:

- Material Optimization: Custom elastomer compounds for extreme temperatures (e.g., liquid nitrogen applications, high-heat engine environments), aggressive chemicals, specific fuel types, or enhanced abrasion resistance (e.g., PTFE-modified compounds). We work with NBR, HNBR, FKM, AEM, VMQ, and FVMQ.

- Geometry & Design Modifications: Adjustments to lip profile, spring force, outer case design (e.g., full metal, rubber-covered), or incorporation of additional dust lips/deflectors for specialized shaft finishes or higher contaminant loads. This includes adapting to non-standard shaft diameters or housing bores.

- Integrated Sealing Systems: Development of multi-component sealing modules that combine oil seals with bearings, wear sleeves, or other components into a single, pre-assembled unit, simplifying installation and improving overall system reliability.

- Surface Treatments & Coatings: Application of specialized low-friction coatings (e.g., PTFE-based) to the sealing lip to reduce torque, minimize heat generation, and extend life in dry-running or marginally lubricated conditions.

- Prototyping & Validation: From initial concept and CAD modeling to rapid prototyping and comprehensive laboratory testing (including dynamic runout, pressure cycling, and life cycle tests), we ensure the custom solution meets all performance criteria before mass production.

Our approach to customization is collaborative, working closely with clients to define requirements, analyze operational parameters, and engineer a sealing solution that delivers optimal performance and cost-efficiency. Our experienced design engineers utilize advanced simulation tools (e.g., FEM analysis) to predict performance and validate designs, reducing development cycles and ensuring first-time-right solutions.

Application Case Studies

Our sealing solutions, including the 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors, have consistently delivered exceptional results in real-world agricultural environments. These case studies highlight our commitment to reliability and performance.

Case Study 1: Heavy-Duty Tractor Front Axle Sealing

Challenge: A leading agricultural OEM experienced premature oil seal failure in the front axle hubs of their high-horsepower tractors. The seals were failing after approximately 1,500 operating hours due to severe dust ingress and dynamic misalignment, leading to costly warranty claims and significant farmer downtime during peak seasons.

Solution: We collaborated with the OEM to analyze the failure modes. Our engineers recommended a customized variant of the 01027784B/AL154055 AL81842 hub oil seal. This involved a multi-lip design with an enhanced auxiliary dust lip geometry for superior contaminant exclusion and a slightly modified FKM material compound optimized for high-abrasion resistance and better elasticity under dynamic shaft conditions. The garter spring tension was also fine-tuned to maintain consistent sealing force despite minor shaft runout.

Result: Post-implementation, field trials demonstrated an average seal lifespan exceeding 4,500 operating hours, representing a 200% improvement. The OEM reported a 70% reduction in warranty claims related to front axle seals, significantly improving customer satisfaction and reducing overall maintenance costs. This success solidified our position as a trusted supplier for their critical sealing needs.

Case Study 2: Harvester Gearbox Oil Retention

Challenge: A major harvester manufacturer faced persistent leakage issues from gearbox output shafts, particularly during extended harvest seasons in hot climates. Standard NBR seals were degrading prematurely due to elevated temperatures and interaction with specialized synthetic gearbox lubricants, leading to lubricant loss and potential gearbox damage.

Solution: We proposed an FKM version of the 01027784B/AL154055 AL81842 hub oil seal, specifically formulated for high-temperature and chemical resistance. This fluoroelastomer variant maintained its mechanical properties and sealing integrity at temperatures up to 180°C and demonstrated excellent compatibility with the OEM's synthetic gearbox oil. Additionally, a slight increase in lip interference was implemented to ensure better retention of the lower viscosity hot lubricant.

Result: The adoption of our FKM seals virtually eliminated gearbox oil leaks, extending the average operational period between lubricant top-offs by over 300%. The harvesters demonstrated improved reliability during critical harvest periods, and the manufacturer benefited from a reduced environmental footprint due to fewer lubricant spills. This solution became a standard component in their high-end harvester models, reflecting confidence in our material science and engineering.

Frequently Asked Questions (FAQ)

Q1: What materials are available for the 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors?

A1: Our standard options include NBR (Nitrile Butadiene Rubber) for general-purpose tractor applications and FKM (Fluoroelastomer) for environments requiring higher temperature resistance, enhanced chemical compatibility with aggressive lubricants, or extended service life. Other specialized elastomers are available for customized solutions.

Q2: How do I ensure proper installation of the 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors?

A2: Proper installation is critical. We recommend using a seal installation tool that presses on the outer diameter of the metal case, ensuring even force. The shaft should be clean, free of burrs, and lubricated. Avoid impacting the sealing lip directly. Detailed installation guides and technical drawings are available upon request.

Q3: What are the key factors affecting the service life of a hub oil seal in a tractor?

A3: Several factors influence service life, including operating temperature, shaft surface finish and hardness, presence of abrasive contaminants, type of lubricant, shaft speed, pressure differential, and proper installation. Our seals are designed to mitigate these factors through advanced material selection and robust construction.

Q4: Can this seal be used in applications with high shaft runout or vibration?

A4: Yes, the garter spring design and compliant elastomer lip of the 01027784B/AL154055 AL81842 hub oil seal are engineered to accommodate typical shaft runout and vibrations encountered in tractor operations. For extreme conditions, our engineering team can recommend specialized designs or materials to enhance performance.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment

We maintain optimized inventory levels for standard configurations of the 01027784B/AL154055 AL81842 hub oil seal 167.819815.5/16 suitable for tractors to ensure rapid fulfillment. Typical lead times for off-the-shelf products range from 3-7 business days for North America and Europe, and 7-14 business days for other international destinations, subject to order volume. For custom-engineered solutions, lead times will be provided with the project proposal, typically ranging from 4-8 weeks for prototyping and validation, followed by agreed-upon production schedules.

Our global logistics network and strategic warehousing enable efficient delivery, minimizing downtime for our B2B clients. We offer various shipping options, including express and freight, to meet urgent requirements.

Warranty Commitments

All our products, including the 01027784B/AL154055 AL81842 hub oil seal, are backed by a comprehensive 12-month limited warranty against manufacturing defects and material flaws from the date of purchase. This warranty underscores our confidence in the quality and durability of our seals. Detailed warranty terms and conditions are available upon request and provided with every order. We are committed to ensuring our seals perform as expected under specified operating conditions, providing peace of mind to our customers.

Dedicated Customer Support

Our commitment extends beyond product delivery. We offer dedicated technical support from experienced engineers and sales professionals, available to assist with product selection, application guidance, troubleshooting, and post-sales inquiries. Our support team is equipped to provide expert advice on seal compatibility, installation best practices, and performance optimization. We pride ourselves on responsive and knowledgeable customer service, ensuring our clients receive the support they need to maximize the operational efficiency and longevity of their machinery.

Contact our sales and technical support team via email at sales@hkaiseal.com or by phone during business hours. We are here to partner with you for long-term success.

References

- ISO 3601-1:2019, Fluid power systems — Housings for O-rings — Part 1: Dimensions of O-rings, A, B and C rings, and their housings. International Organization for Standardization.

- ASTM D2000, Standard Classification System for Rubber Products in Automotive Applications. ASTM International.

- DIN 3760, Radial shaft seals for rotary shafts — Dimensions. Deutsches Institut für Normung.

- Schenck, W. "The Science of Rubber Sealing: Design, Manufacturing, and Application." Springer, 2018.

- "Sealing Technology in Agricultural Machinery." SAE International Journal of Commercial Vehicles, Vol. 12, Issue 3, 2022.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories