Mar . 06, 2025 16:05 Back to list

185*205*11 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

Authoritative resources on this subject delve deep into the materials science behind oil seal technologies. Renowned manufacturers and materials scientists contribute to the development and refinement of these seals, utilizing cutting-edge research to push the boundaries of endurance and functionality. Industry standards and certifications further validate the reliability of these components, offering peace of mind to engineers and purchasing managers alike. Trustworthiness in an oil seal is as much about the brand reputation as it is about empirical data substantiating its claims. Reputable manufacturers provide comprehensive performance data and testing results, giving professionals confidence in the seal's capabilities. Furthermore, technical documentation often includes detailed installation and maintenance guidelines to maximize the seal’s lifespan and efficacy. Conversely, real-world experience shared by industry veterans and machine operators often highlights the practical issues faced during installation and operation. Detailed anecdotes and case studies where the 31x43x10 5 oil seal excelled or faced challenges provide invaluable insights that escape conventional technical manuals. These firsthand accounts are essential, painting a complete picture of the seal’s behavior in diverse scenarios and empowering informed decision-making for future purchases or replacements. An investment in quality oil seals like the 31x43x10 5 often pays dividends through reduced downtime, improved safety, and sustained equipment performance. In an environment where every component must work harmoniously, understanding, and selecting the right oil seal becomes not just a technical choice, but a strategic decision that reflects a commitment to quality and operational excellence. This meticulous process underscores the broader philosophy that underpins robust machine maintenance strategies, where every element is crucial in ensuring the integrity and success of complex mechanical systems.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

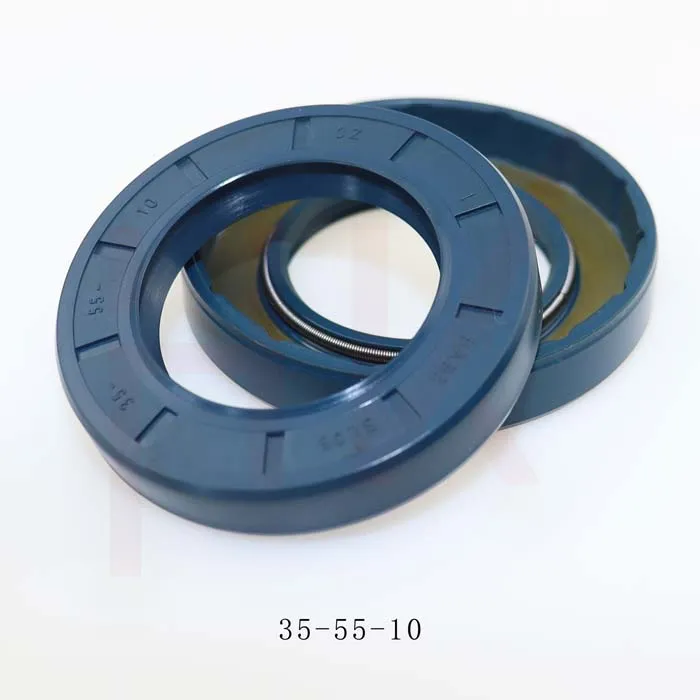

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories