Sep . 15, 2024 16:22 Back to list

High-Quality 25x47x7 Oil Seal - Durable and Reliable Sealing Solutions

The Importance of the 25x47x7 mm Oil Seal in Mechanical Applications

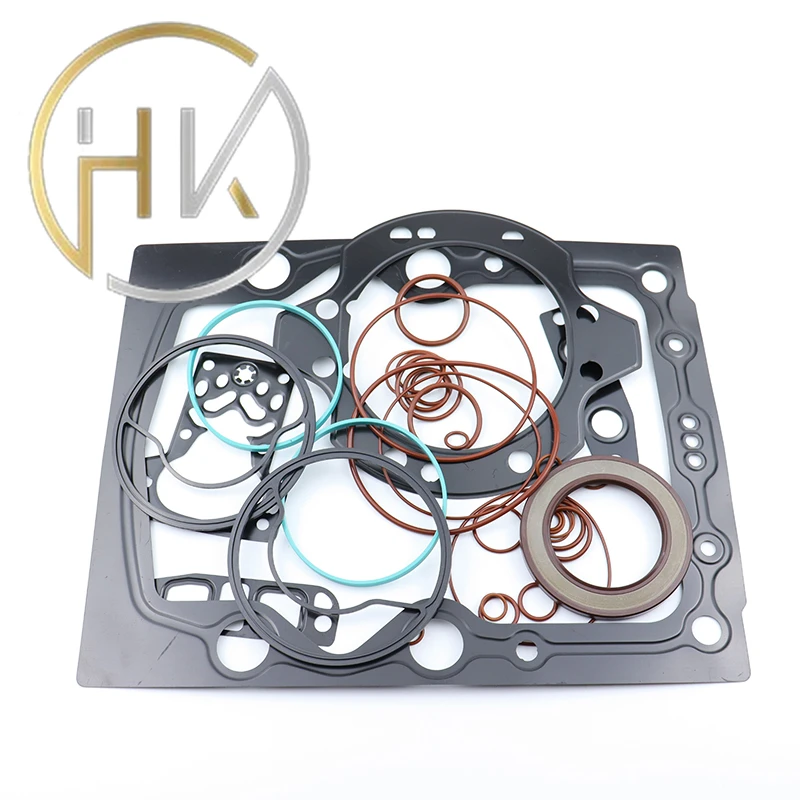

In the world of machinery and mechanical engineering, oil seals play a critical role in ensuring the smooth operation of various components. One such crucial component is the 25x47x7 mm oil seal, known for its effectiveness in preventing lubricant leakage and protecting machinery from contaminants.

Understanding Oil Seals

Oil seals, often referred to as grease seals or lip seals, are devices designed to retain lubricants within a bearing or housing while preventing external contaminants from entering. The designation 25x47x7 mm indicates the dimensions of the seal, with a diameter of 25 mm for the inner dimension, 47 mm for the outer dimension, and a thickness of 7 mm. This specific size makes the 25x47x7 oil seal suitable for a variety of applications in automotive, industrial, and agricultural machinery.

Applications

The versatility of the 25x47x7 oil seal allows it to be utilized in numerous applications. In the automotive industry, it is commonly found in transmissions, differential housings, and engine components, where it is essential for maintaining lubrication and preventing oil leaks. In industrial settings, it is employed in pumps, motors, and gearboxes, where reliability and efficiency are paramount. Additionally, agricultural machinery relies on this oil seal to ensure the longevity and performance of equipment by safeguarding against dirt and moisture.

25x47x7 oil seal

Advantages

One of the primary advantages of the 25x47x7 oil seal is its ability to withstand various operating conditions. Made from durable materials like rubber or silicone, these seals exhibit excellent resistance to heat, abrasion, and chemical exposure. This resilience helps to extend the lifespan of machinery, thereby reducing maintenance costs and downtime. Moreover, the design of the seal provides effective lip action that ensures minimal friction, contributing to optimal performance.

Installation and Maintenance

Proper installation of the 25x47x7 oil seal is crucial for its effectiveness. It is essential to ensure that the seal is correctly aligned and seated in its housing to prevent premature wear or leakage. Regular inspection and maintenance can further enhance the seal's performance. Signs of wear, such as oil leaks or debris in the lubrication system, should be addressed immediately to prevent damage to machinery.

Conclusion

In conclusion, the 25x47x7 mm oil seal is an indispensable component in a wide range of mechanical applications. Its ability to retain lubricants while keeping contaminants at bay underscores its importance in enhancing the reliability and efficiency of machinery. Through proper installation and maintenance, operators can ensure that their equipment operates smoothly, ultimately leading to increased productivity and reduced operational costs. As technology continues to evolve, the role of oil seals in machinery will only become more critical, making them a key focus for engineers and manufacturers alike.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories