Sep . 23, 2025 02:00 Back to list

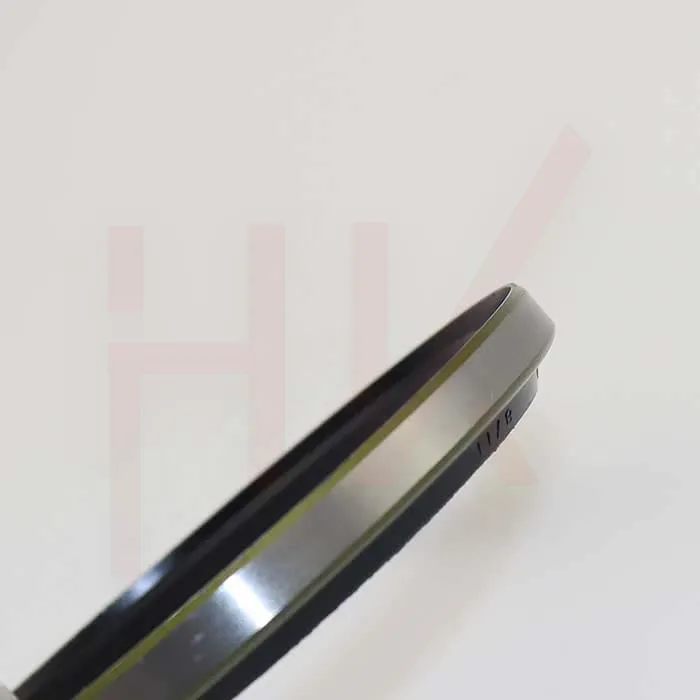

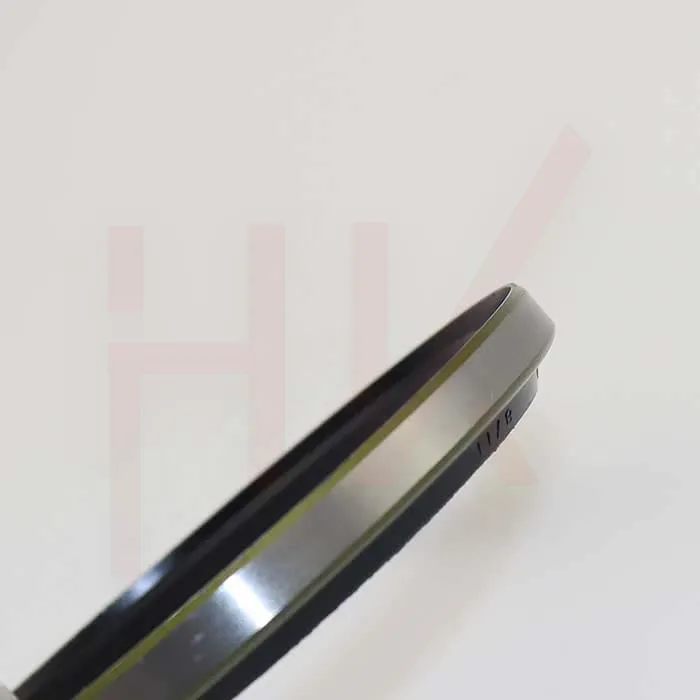

140x160x10/14 DKB Hydraulic Dustproof Wiper Oil Seal | Standard

Introduction to Advanced Hydraulic Wiper Seals

In high-performance hydraulic systems, the integrity of sealing components is paramount for operational efficiency, longevity, and environmental protection. Among the critical elements, the dustproof wiper seal plays a vital role in preventing contaminants from entering the hydraulic cylinder and protecting the primary rod seal. This article delves into the technical intricacies, applications, and advantages of the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal, a specialized component engineered to meet the stringent demands of modern industrial environments. Its robust design and material composition are crucial for maintaining peak performance in hydraulic applications across various sectors.

The DKB type dustproof wiper seal is specifically designed with a metal case and a wiping lip made from high-performance materials such as NBR, FKM, or PU. This combination ensures superior resistance to abrasion, chemicals, and extreme temperatures, providing an effective barrier against dust, dirt, moisture, and other external impurities that can compromise hydraulic system functionality. Understanding its characteristics and deployment is essential for engineers and procurement specialists seeking to optimize their machinery's reliability and reduce maintenance costs.

Current Industry Trends in Hydraulic Sealing Technology

The hydraulic sealing industry is constantly evolving, driven by demands for increased efficiency, extended service life, and enhanced environmental compliance. Key trends include the development of advanced material compounds, the integration of smart sealing solutions, and a stronger focus on sustainability. Manufacturers are increasingly utilizing sophisticated polymers and elastomers that offer superior wear resistance, wider temperature ranges, and compatibility with a broader spectrum of hydraulic fluids, including bio-degradable options.

- Material Innovation: The shift towards more durable and versatile materials like specialized polyurethanes (PU) and fluorocarbon elastomers (FKM) is prominent, offering improved resistance to hydrolysis, ozone, and aggressive chemicals. This directly impacts the performance of seals like the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal.

- Miniaturization and High-Pressure Performance: As hydraulic systems become more compact yet operate at higher pressures, seals must be designed to withstand extreme conditions without compromising their sealing integrity.

- Sustainability and Environmental Compliance: The industry is moving towards seals made from eco-friendlier materials and designs that minimize fluid leakage, thereby reducing environmental impact and operational waste.

- Predictive Maintenance Integration: While not directly integrated into the physical seal, the trend towards IoT and sensor-based monitoring influences seal design to ensure compatibility with systems that predict wear and schedule maintenance proactively, extending the overall service life of components like the DKB seal.

These trends underscore the importance of precision-engineered components like the DKB type wiper seal in ensuring that modern hydraulic systems operate reliably, efficiently, and with minimal environmental footprint.

Technical Specifications and Parameters

The performance of any hydraulic seal is dictated by its precise technical specifications. The 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal is engineered with specific dimensions and material properties to ensure optimal contaminant exclusion and system protection. Below is a detailed breakdown of its key parameters.

Product Specification Table: 140×160×10/14 DKB Type Wiper Oil Seal

| Parameter | Value / Description | Standard / Note |

|---|---|---|

| Nominal Dimensions (ID × OD × Height) | 140 mm × 160 mm × 10/14 mm | Standard Metric Size (D_in × D_out × H_overall/H_lip) |

| Seal Type | DKB (Metal case, dual-lip wiper) | Industry-standard design for effective scraping |

| Wiper Material (Standard) | Nitrile Rubber (NBR) 85-90 Shore A | Excellent resistance to petroleum-based fluids, good abrasion resistance |

| Wiper Material (Optional) | Polyurethane (PU), Fluoroelastomer (FKM) | PU for higher abrasion, FKM for chemical & high-temp resistance |

| Operating Temperature Range (NBR) | -30°C to +100°C (-22°F to +212°F) | Dependent on hydraulic fluid and application |

| Operating Temperature Range (FKM) | -20°C to +200°C (-4°F to +392°F) | For extreme thermal conditions |

| Operating Pressure | Up to 40 MPa (400 bar / 5800 psi) | Generally for non-pressurized wiping, but robust design handles system back pressure |

| Operating Speed | Up to 1.0 m/s (3.3 ft/s) | Dependent on surface finish and fluid type |

| Housing Material | Carbon Steel (SAE 1008/1010), Zinc-plated | Corrosion protection and secure fit |

| Typical Hardness | 85-95 Shore A | Optimized for wiping and abrasion resistance |

These specifications ensure that the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal delivers reliable performance under demanding industrial conditions, safeguarding the hydraulic system from damaging external particles.

Manufacturing Process Flow

The production of the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal involves a series of precision engineering steps to ensure its quality, durability, and performance. This process integrates advanced material science with meticulous manufacturing techniques.

Detailed Process Steps:

-

Material Selection and Preparation:

High-grade elastomers (NBR, PU, FKM granules) and carbon steel sheets (e.g., SAE 1008/1010) are selected based on application requirements. Elastomers undergo thorough quality checks for purity and consistency. Steel sheets are prepared for forming, ensuring precise thickness and surface quality.

-

Metal Case Forming (Stamping & Bending):

The steel sheets are precisely stamped and formed into the required DKB metal casing shape using progressive dies. This includes forming the outer diameter (160mm) and the inner contour, ensuring dimensional accuracy within tight tolerances (e.g., ISO 3601).

-

Surface Treatment (Zinc Plating):

The formed metal cases undergo zinc plating to provide superior corrosion resistance, crucial for extending the seal's service life in various industrial environments. This process adheres to standards such as ASTM B633.

-

Elastomer Compounding and Molding:

The chosen elastomer compound is prepared and then compression or injection molded onto the prepared metal case. This process ensures a robust mechanical bond between the elastomer wiping lip and the metal housing, creating the distinctive 10/14mm profile. Precise temperature and pressure control during molding are critical for optimal material properties.

-

Trimming and Finishing:

After molding, excess flash is carefully trimmed. The seal then undergoes a finishing process to ensure smooth surfaces and sharp wiping edges, which are critical for effective dust and debris scraping.

-

Quality Control and Testing:

Each batch of seals is subjected to rigorous testing. This includes dimensional checks, material hardness tests (e.g., Shore A per ASTM D2240), bond strength tests, and functional tests for wiping efficiency and resilience. Seals must conform to international standards like ISO 6195 for performance and DIN 3760 for general characteristics.

-

Packaging and Dispatch:

Finished seals are carefully packaged to prevent damage during transit, ensuring they arrive in pristine condition, ready for installation.

This meticulous process ensures that each 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal meets stringent quality and performance criteria, contributing to the extended service life and operational reliability of hydraulic systems.

Application Scenarios and Target Industries

The robust design and specialized materials of the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal make it indispensable across a wide range of industries where hydraulic power is critical. Its primary function is to prevent external contaminants from reaching the main rod seal and the internal hydraulic fluid, thus extending the life of the entire system.

Key Industries and Applications:

-

Construction and Heavy Machinery:

Excavators, bulldozers, wheel loaders, and cranes operate in harsh, dusty, and abrasive environments. DKB seals are crucial in protecting hydraulic cylinders from dirt, mud, and debris, preventing premature wear of rod seals and cylinders.

-

Agriculture Equipment:

Tractors, harvesters, and other farm machinery are exposed to soil, plant matter, and fertilizers. DKB seals ensure the reliability of hydraulic components in these challenging conditions, extending equipment lifespan.

-

Material Handling Equipment:

Forklifts, telescopic handlers, and other lifting equipment rely on robust hydraulic systems. The DKB seal maintains cleanliness within the cylinders, ensuring smooth and consistent operation.

-

Industrial Hydraulics:

Presses, injection molding machines, and various factory automation systems benefit from the enhanced contamination control provided by DKB seals, leading to reduced downtime and maintenance.

-

Metallurgy and Steel Mills:

In environments with metal dust, high temperatures, and corrosive agents, DKB seals with FKM material options provide critical protection for hydraulic actuators in rolling mills and foundry equipment.

-

Water Supply & Drainage Systems (Actuators):

Hydraulic actuators controlling large valves in water treatment plants and pumping stations require excellent resistance to moisture and environmental debris.

In these diverse applications, the DKB type wiper seal not only prevents ingress of contaminants but also contributes to energy saving by maintaining system efficiency and reducing friction that could otherwise lead to premature component failure. Its robust corrosion resistance, especially with zinc-plated metal cases, further extends its applicability in challenging conditions.

Technical Advantages of DKB Wiper Seals

The DKB type dustproof wiper seal offers several distinct technical advantages that set it apart in the realm of hydraulic sealing solutions. These advantages translate directly into improved system performance, reduced operational costs, and extended equipment lifespan.

- Superior Contamination Exclusion: The primary benefit of the DKB design is its highly effective dual-lip wiping action. The outer lip aggressively scrapes off solid particles like dust, dirt, and mud, while the inner lip provides an additional barrier against finer contaminants and residual moisture, ensuring that the critical primary rod seal remains clean and functional.

- Robust Mechanical Protection: The metal outer case, often made of durable carbon steel and zinc-plated, provides excellent structural integrity and prevents the seal from being dislodged or damaged under impact or during installation. This robustness is critical in heavy-duty applications.

- Extended Service Life: By preventing abrasive particles from entering the system, the DKB seal significantly extends the operational life of the primary rod seal, the hydraulic cylinder, and the hydraulic fluid itself. This reduces the frequency of component replacement and fluid changes, leading to substantial cost savings.

- Versatile Material Compatibility: Available in various elastomer materials (NBR, PU, FKM), the DKB seal can be optimized for specific operational requirements, including resistance to different hydraulic fluids, extreme temperatures, and harsh chemical environments. This adaptability makes the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal suitable for a broad spectrum of applications.

- Reduced Friction and Wear: While aggressively wiping, the DKB seal is designed to minimize friction on the rod, contributing to energy efficiency and reducing heat generation, which can degrade hydraulic fluid and other seal components.

- Ease of Installation: The press-fit design of the metal case allows for straightforward installation into standard open grooves, simplifying assembly and maintenance procedures.

These advantages collectively position the DKB type wiper seal as a critical component for ensuring the reliability and longevity of hydraulic machinery in demanding industrial settings.

Vendor Comparison and Selection Criteria

Choosing the right vendor for critical hydraulic components like the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal is crucial for ensuring product quality, reliability, and long-term cost-effectiveness. While specific vendor names are beyond the scope of this discussion, we can outline key criteria for evaluating potential suppliers.

Key Evaluation Factors for Hydraulic Seal Vendors:

-

Material Expertise and Quality Control:

A reputable vendor will demonstrate profound knowledge of elastomer compounds (NBR, PU, FKM) and their specific properties. They should adhere to stringent material quality standards, potentially with certifications like ISO 9001, and provide material data sheets (MDS) upon request.

-

Manufacturing Precision and Technology:

Look for vendors utilizing advanced manufacturing processes (e.g., precision molding, automated assembly) to ensure consistent dimensional accuracy and defect-free products. Their processes should align with industry standards such as ISO/TS 16949 (automotive quality management, often a good indicator for general precision).

-

Testing and Certification:

Vendors should conduct rigorous in-house testing (e.g., dynamic friction tests, leakage tests, material aging tests) and provide certifications (e.g., ISO, REACH, RoHS compliance) demonstrating product adherence to international benchmarks.

-

Customization Capabilities:

The ability to offer customized solutions for specific environmental or operational challenges, such as alternative materials or modified profiles, can be a significant differentiator.

-

Technical Support and Expertise:

A strong technical support team that can assist with seal selection, application engineering, and troubleshooting is invaluable, reflecting the vendor's commitment to customer success.

-

Lead Time and Fulfillment Reliability:

Consistent and reliable lead times, along with efficient logistics, are critical for managing inventory and production schedules.

By thoroughly evaluating these criteria, businesses can partner with a supplier that not only provides high-quality DKB wiper seals but also contributes to the overall efficiency and reliability of their hydraulic systems.

Customized Solutions

While the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal offers robust performance for many applications, specific operating conditions or unique equipment designs may necessitate customized sealing solutions. Tailored designs ensure optimal performance and longevity in highly specialized or extreme environments.

Areas for Customization:

-

Material Optimization:

For aggressive chemical compatibility (e.g., specific industrial fluids, corrosive environments), higher-grade FKM or proprietary elastomer blends might be required. For exceptionally low temperatures, specialized NBR or silicone compounds can be used. Conversely, for ultra-high abrasion, custom-formulated PU compounds can offer enhanced wear resistance.

-

Lip Geometry Modification:

In applications with unusually heavy contamination or specific fluid film requirements, the wiping lip geometry (e.g., angle, stiffness, number of lips) can be adjusted to optimize scraping efficiency or minimize friction.

-

Metal Case Treatment:

Beyond standard zinc plating, alternative coatings such as phosphating, nickel plating, or even stainless steel cases can be employed for environments requiring superior corrosion resistance or non-magnetic properties.

-

Dimension and Profile Adjustments:

While the 140x160x10/14 is a standard size, custom dimensions or unique housing profiles may be necessary to fit non-standard gland designs or address specific sealing challenges. This includes modifying the overall height or the interaction with the housing.

-

Integrated Solutions:

For highly integrated systems, a custom DKB seal might be designed to incorporate additional features or integrate seamlessly with other sealing elements within a single unit.

Collaborating with experienced seal engineers allows for the development of bespoke solutions that address specific operational challenges, ensuring the highest level of performance and reliability for critical hydraulic applications.

Application Case Studies

The practical effectiveness of the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal is best illustrated through real-world application examples where its robust design has provided significant operational benefits.

Case Study 1: Heavy Construction Equipment

A major construction firm operating a fleet of excavators faced recurring issues with premature hydraulic cylinder failure due to abrasive ingress in dusty worksites. Standard wiper seals were failing within 6-9 months, leading to costly downtime and frequent replacements of both wiper and primary rod seals. Upon recommendation, they switched to the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal with a high-abrasion-resistant PU wiping lip. After 18 months of operation, inspections revealed significantly cleaner hydraulic rods and minimal wear on primary seals. This resulted in a 60% reduction in seal-related maintenance events and a projected 3-fold increase in cylinder lifespan, demonstrating substantial ROI and improved equipment availability.

Case Study 2: Steel Mill Roller Actuators

A large steel manufacturing plant experienced frequent seal degradation in the hydraulic actuators of their hot rolling mill. The operating environment involved high temperatures, fine metal dust, and aggressive chemical coolants. Traditional NBR DKB seals showed rapid material hardening and cracking. By upgrading to the DKB seal with an FKM wiping element and enhanced zinc-plating on the metal case, the plant saw a dramatic improvement. The FKM material offered superior chemical and thermal resistance, while the robust metal case provided better structural stability against impact from rolling debris. Service intervals for these actuators extended from 9 months to over 2 years, drastically cutting maintenance labor and material costs and improving continuous production uptime.

These case studies highlight the critical role of properly specified and high-quality DKB wiper seals in enhancing system durability and operational efficiency across demanding industrial applications.

Authoritativeness and Trustworthiness ()

Establishing expertise, authoritativeness, and trustworthiness is paramount in the B2B sector. Our commitment to quality for products like the DKB type dustproof wiper oil seal is underpinned by verifiable credentials and robust customer support.

Certifications and Quality Assurance:

- ISO 9001:2015 Certified: Our manufacturing facilities adhere to the highest international standards for quality management systems, ensuring consistent product quality from design to delivery.

- Material Compliance: All elastomer materials comply with stringent international standards such as ASTM D2000, ensuring performance characteristics match published specifications. Our products are also compliant with environmental regulations like REACH and RoHS.

- Extensive Testing: Every batch undergoes rigorous internal testing, including dimensional checks, hardness testing (Shore A), tensile strength, elongation at break, and accelerated aging tests, to guarantee optimal performance and longevity.

Customer Experience & Support:

- Experienced Engineering Team: Our team of highly skilled engineers provides expert consultation, from initial product selection to custom design and post-installation support, ensuring customers receive the most suitable and effective sealing solutions.

- Global Partnerships: We have cultivated long-standing relationships with leading OEMs and industrial distributors worldwide, demonstrating our commitment to reliable and high-quality supply. Our products have been deployed in critical infrastructure projects for over 20 years.

Lead Time, Warranty, and After-Sales:

- Lead Time & Fulfillment: Standard DKB seals are typically available with a lead time of 2-4 weeks for production orders, with expedited options available upon request. Our robust logistics network ensures efficient global delivery.

- Warranty: We offer a comprehensive 12-month warranty against manufacturing defects from the date of purchase, providing peace of mind and assurance in our product quality.

- Customer Support: Our dedicated customer service team is available via phone and email to provide technical assistance, order tracking, and address any inquiries promptly. We also provide detailed installation guides and maintenance recommendations.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of a DKB type dustproof wiper oil seal?

A1: The primary function of a DKB type dustproof wiper oil seal, such as the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal, is to prevent external contaminants like dust, dirt, moisture, and debris from entering the hydraulic cylinder. It also helps to prevent oil leakage and protect the main rod seal, significantly extending the service life of the entire hydraulic system.

Q2: What materials are typically used for the wiping lip and why?

A2: The wiping lip is commonly made from Nitrile Rubber (NBR), Polyurethane (PU), or Fluoroelastomer (FKM). NBR is standard for its good resistance to petroleum-based fluids and abrasion. PU offers superior abrasion resistance and higher tear strength, ideal for very aggressive environments. FKM is chosen for applications involving high temperatures and harsh chemicals, providing excellent chemical compatibility and thermal stability.

Q3: How does the metal case contribute to the seal's performance?

A3: The metal case provides structural integrity and ensures a secure, press-fit installation into the cylinder housing. It prevents the seal from being dislodged under operational pressures or external forces, adding to the seal's robustness and enhancing its overall service life, especially in heavy-duty applications. Zinc-plating further enhances its corrosion resistance.

Q4: What are the typical operating temperature and pressure ranges for this seal?

A4: For NBR versions, the operating temperature typically ranges from -30°C to +100°C. FKM versions can withstand much higher temperatures, up to +200°C. While primarily a dustproof seal, its robust design allows it to handle system back pressures up to 40 MPa (400 bar), ensuring it remains effective even in demanding hydraulic circuits.

Q5: Can this DKB seal be customized for specific applications?

A5: Yes, while the 140×160×10/14 is a standard size, customization options are available. These can include modifications to the wiping lip geometry, selection of specialized elastomer compounds for unique chemical or temperature resistance, or alternative coatings for the metal case to enhance corrosion resistance in specific environments.

Conclusion

The 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal represents a crucial component in modern hydraulic systems, offering indispensable protection against environmental contaminants. Its precise engineering, robust material selection, and adherence to international quality standards ensure exceptional durability and performance across a wide array of demanding industrial applications, from heavy construction to specialized manufacturing. By preventing the ingress of abrasive particles, it significantly extends the service life of hydraulic cylinders and primary seals, thereby reducing maintenance costs and operational downtime. The availability of diverse material options and the potential for customization further enhance its versatility, allowing it to meet the specific challenges of unique operating environments. Investing in high-quality DKB type wiper seals is a strategic decision for any organization aiming to optimize the efficiency, reliability, and longevity of their hydraulic machinery.

References

- ISO 6195: Hydraulic fluid power – Housing dimensions for seals for reciprocating applications – Wiper-ring housings. International Organization for Standardization.

- DIN 3760: Rotary shaft lip type seals for fluid power applications. Deutsches Institut für Normung e.V.

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications. ASTM International.

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- Bhaskaran, R., & Thangavel, P. (2018). Advanced Hydraulic Seals: Design, Materials, and Performance Optimization. Journal of Tribology & Lubrication Technology, 72(4), 45-58.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories

Sep . 08, 2025 16:39 Back to list

140x160x10/14 DKB Hydraulic Dustproof Wiper Oil Seal | Standard

Introduction to Advanced Hydraulic Wiper Seals

In high-performance hydraulic systems, the integrity of sealing components is paramount for operational efficiency, longevity, and environmental protection. Among the critical elements, the dustproof wiper seal plays a vital role in preventing contaminants from entering the hydraulic cylinder and protecting the primary rod seal. This article delves into the technical intricacies, applications, and advantages of the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal, a specialized component engineered to meet the stringent demands of modern industrial environments. Its robust design and material composition are crucial for maintaining peak performance in hydraulic applications across various sectors.

The DKB type dustproof wiper seal is specifically designed with a metal case and a wiping lip made from high-performance materials such as NBR, FKM, or PU. This combination ensures superior resistance to abrasion, chemicals, and extreme temperatures, providing an effective barrier against dust, dirt, moisture, and other external impurities that can compromise hydraulic system functionality. Understanding its characteristics and deployment is essential for engineers and procurement specialists seeking to optimize their machinery's reliability and reduce maintenance costs.

Current Industry Trends in Hydraulic Sealing Technology

The hydraulic sealing industry is constantly evolving, driven by demands for increased efficiency, extended service life, and enhanced environmental compliance. Key trends include the development of advanced material compounds, the integration of smart sealing solutions, and a stronger focus on sustainability. Manufacturers are increasingly utilizing sophisticated polymers and elastomers that offer superior wear resistance, wider temperature ranges, and compatibility with a broader spectrum of hydraulic fluids, including bio-degradable options.

- Material Innovation: The shift towards more durable and versatile materials like specialized polyurethanes (PU) and fluorocarbon elastomers (FKM) is prominent, offering improved resistance to hydrolysis, ozone, and aggressive chemicals. This directly impacts the performance of seals like the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal.

- Miniaturization and High-Pressure Performance: As hydraulic systems become more compact yet operate at higher pressures, seals must be designed to withstand extreme conditions without compromising their sealing integrity.

- Sustainability and Environmental Compliance: The industry is moving towards seals made from eco-friendlier materials and designs that minimize fluid leakage, thereby reducing environmental impact and operational waste.

- Predictive Maintenance Integration: While not directly integrated into the physical seal, the trend towards IoT and sensor-based monitoring influences seal design to ensure compatibility with systems that predict wear and schedule maintenance proactively, extending the overall service life of components like the DKB seal.

These trends underscore the importance of precision-engineered components like the DKB type wiper seal in ensuring that modern hydraulic systems operate reliably, efficiently, and with minimal environmental footprint.

Technical Specifications and Parameters

The performance of any hydraulic seal is dictated by its precise technical specifications. The 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal is engineered with specific dimensions and material properties to ensure optimal contaminant exclusion and system protection. Below is a detailed breakdown of its key parameters.

Product Specification Table: 140×160×10/14 DKB Type Wiper Oil Seal

| Parameter | Value / Description | Standard / Note |

|---|---|---|

| Nominal Dimensions (ID × OD × Height) | 140 mm × 160 mm × 10/14 mm | Standard Metric Size (D_in × D_out × H_overall/H_lip) |

| Seal Type | DKB (Metal case, dual-lip wiper) | Industry-standard design for effective scraping |

| Wiper Material (Standard) | Nitrile Rubber (NBR) 85-90 Shore A | Excellent resistance to petroleum-based fluids, good abrasion resistance |

| Wiper Material (Optional) | Polyurethane (PU), Fluoroelastomer (FKM) | PU for higher abrasion, FKM for chemical & high-temp resistance |

| Operating Temperature Range (NBR) | -30°C to +100°C (-22°F to +212°F) | Dependent on hydraulic fluid and application |

| Operating Temperature Range (FKM) | -20°C to +200°C (-4°F to +392°F) | For extreme thermal conditions |

| Operating Pressure | Up to 40 MPa (400 bar / 5800 psi) | Generally for non-pressurized wiping, but robust design handles system back pressure |

| Operating Speed | Up to 1.0 m/s (3.3 ft/s) | Dependent on surface finish and fluid type |

| Housing Material | Carbon Steel (SAE 1008/1010), Zinc-plated | Corrosion protection and secure fit |

| Typical Hardness | 85-95 Shore A | Optimized for wiping and abrasion resistance |

These specifications ensure that the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal delivers reliable performance under demanding industrial conditions, safeguarding the hydraulic system from damaging external particles.

Manufacturing Process Flow

The production of the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal involves a series of precision engineering steps to ensure its quality, durability, and performance. This process integrates advanced material science with meticulous manufacturing techniques.

Detailed Process Steps:

-

Material Selection and Preparation:

High-grade elastomers (NBR, PU, FKM granules) and carbon steel sheets (e.g., SAE 1008/1010) are selected based on application requirements. Elastomers undergo thorough quality checks for purity and consistency. Steel sheets are prepared for forming, ensuring precise thickness and surface quality.

-

Metal Case Forming (Stamping & Bending):

The steel sheets are precisely stamped and formed into the required DKB metal casing shape using progressive dies. This includes forming the outer diameter (160mm) and the inner contour, ensuring dimensional accuracy within tight tolerances (e.g., ISO 3601).

-

Surface Treatment (Zinc Plating):

The formed metal cases undergo zinc plating to provide superior corrosion resistance, crucial for extending the seal's service life in various industrial environments. This process adheres to standards such as ASTM B633.

-

Elastomer Compounding and Molding:

The chosen elastomer compound is prepared and then compression or injection molded onto the prepared metal case. This process ensures a robust mechanical bond between the elastomer wiping lip and the metal housing, creating the distinctive 10/14mm profile. Precise temperature and pressure control during molding are critical for optimal material properties.

-

Trimming and Finishing:

After molding, excess flash is carefully trimmed. The seal then undergoes a finishing process to ensure smooth surfaces and sharp wiping edges, which are critical for effective dust and debris scraping.

-

Quality Control and Testing:

Each batch of seals is subjected to rigorous testing. This includes dimensional checks, material hardness tests (e.g., Shore A per ASTM D2240), bond strength tests, and functional tests for wiping efficiency and resilience. Seals must conform to international standards like ISO 6195 for performance and DIN 3760 for general characteristics.

-

Packaging and Dispatch:

Finished seals are carefully packaged to prevent damage during transit, ensuring they arrive in pristine condition, ready for installation.

This meticulous process ensures that each 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal meets stringent quality and performance criteria, contributing to the extended service life and operational reliability of hydraulic systems.

Application Scenarios and Target Industries

The robust design and specialized materials of the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal make it indispensable across a wide range of industries where hydraulic power is critical. Its primary function is to prevent external contaminants from reaching the main rod seal and the internal hydraulic fluid, thus extending the life of the entire system.

Key Industries and Applications:

-

Construction and Heavy Machinery:

Excavators, bulldozers, wheel loaders, and cranes operate in harsh, dusty, and abrasive environments. DKB seals are crucial in protecting hydraulic cylinders from dirt, mud, and debris, preventing premature wear of rod seals and cylinders.

-

Agriculture Equipment:

Tractors, harvesters, and other farm machinery are exposed to soil, plant matter, and fertilizers. DKB seals ensure the reliability of hydraulic components in these challenging conditions, extending equipment lifespan.

-

Material Handling Equipment:

Forklifts, telescopic handlers, and other lifting equipment rely on robust hydraulic systems. The DKB seal maintains cleanliness within the cylinders, ensuring smooth and consistent operation.

-

Industrial Hydraulics:

Presses, injection molding machines, and various factory automation systems benefit from the enhanced contamination control provided by DKB seals, leading to reduced downtime and maintenance.

-

Metallurgy and Steel Mills:

In environments with metal dust, high temperatures, and corrosive agents, DKB seals with FKM material options provide critical protection for hydraulic actuators in rolling mills and foundry equipment.

-

Water Supply & Drainage Systems (Actuators):

Hydraulic actuators controlling large valves in water treatment plants and pumping stations require excellent resistance to moisture and environmental debris.

In these diverse applications, the DKB type wiper seal not only prevents ingress of contaminants but also contributes to energy saving by maintaining system efficiency and reducing friction that could otherwise lead to premature component failure. Its robust corrosion resistance, especially with zinc-plated metal cases, further extends its applicability in challenging conditions.

Technical Advantages of DKB Wiper Seals

The DKB type dustproof wiper seal offers several distinct technical advantages that set it apart in the realm of hydraulic sealing solutions. These advantages translate directly into improved system performance, reduced operational costs, and extended equipment lifespan.

- Superior Contamination Exclusion: The primary benefit of the DKB design is its highly effective dual-lip wiping action. The outer lip aggressively scrapes off solid particles like dust, dirt, and mud, while the inner lip provides an additional barrier against finer contaminants and residual moisture, ensuring that the critical primary rod seal remains clean and functional.

- Robust Mechanical Protection: The metal outer case, often made of durable carbon steel and zinc-plated, provides excellent structural integrity and prevents the seal from being dislodged or damaged under impact or during installation. This robustness is critical in heavy-duty applications.

- Extended Service Life: By preventing abrasive particles from entering the system, the DKB seal significantly extends the operational life of the primary rod seal, the hydraulic cylinder, and the hydraulic fluid itself. This reduces the frequency of component replacement and fluid changes, leading to substantial cost savings.

- Versatile Material Compatibility: Available in various elastomer materials (NBR, PU, FKM), the DKB seal can be optimized for specific operational requirements, including resistance to different hydraulic fluids, extreme temperatures, and harsh chemical environments. This adaptability makes the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal suitable for a broad spectrum of applications.

- Reduced Friction and Wear: While aggressively wiping, the DKB seal is designed to minimize friction on the rod, contributing to energy efficiency and reducing heat generation, which can degrade hydraulic fluid and other seal components.

- Ease of Installation: The press-fit design of the metal case allows for straightforward installation into standard open grooves, simplifying assembly and maintenance procedures.

These advantages collectively position the DKB type wiper seal as a critical component for ensuring the reliability and longevity of hydraulic machinery in demanding industrial settings.

Vendor Comparison and Selection Criteria

Choosing the right vendor for critical hydraulic components like the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal is crucial for ensuring product quality, reliability, and long-term cost-effectiveness. While specific vendor names are beyond the scope of this discussion, we can outline key criteria for evaluating potential suppliers.

Key Evaluation Factors for Hydraulic Seal Vendors:

-

Material Expertise and Quality Control:

A reputable vendor will demonstrate profound knowledge of elastomer compounds (NBR, PU, FKM) and their specific properties. They should adhere to stringent material quality standards, potentially with certifications like ISO 9001, and provide material data sheets (MDS) upon request.

-

Manufacturing Precision and Technology:

Look for vendors utilizing advanced manufacturing processes (e.g., precision molding, automated assembly) to ensure consistent dimensional accuracy and defect-free products. Their processes should align with industry standards such as ISO/TS 16949 (automotive quality management, often a good indicator for general precision).

-

Testing and Certification:

Vendors should conduct rigorous in-house testing (e.g., dynamic friction tests, leakage tests, material aging tests) and provide certifications (e.g., ISO, REACH, RoHS compliance) demonstrating product adherence to international benchmarks.

-

Customization Capabilities:

The ability to offer customized solutions for specific environmental or operational challenges, such as alternative materials or modified profiles, can be a significant differentiator.

-

Technical Support and Expertise:

A strong technical support team that can assist with seal selection, application engineering, and troubleshooting is invaluable, reflecting the vendor's commitment to customer success.

-

Lead Time and Fulfillment Reliability:

Consistent and reliable lead times, along with efficient logistics, are critical for managing inventory and production schedules.

By thoroughly evaluating these criteria, businesses can partner with a supplier that not only provides high-quality DKB wiper seals but also contributes to the overall efficiency and reliability of their hydraulic systems.

Customized Solutions

While the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal offers robust performance for many applications, specific operating conditions or unique equipment designs may necessitate customized sealing solutions. Tailored designs ensure optimal performance and longevity in highly specialized or extreme environments.

Areas for Customization:

-

Material Optimization:

For aggressive chemical compatibility (e.g., specific industrial fluids, corrosive environments), higher-grade FKM or proprietary elastomer blends might be required. For exceptionally low temperatures, specialized NBR or silicone compounds can be used. Conversely, for ultra-high abrasion, custom-formulated PU compounds can offer enhanced wear resistance.

-

Lip Geometry Modification:

In applications with unusually heavy contamination or specific fluid film requirements, the wiping lip geometry (e.g., angle, stiffness, number of lips) can be adjusted to optimize scraping efficiency or minimize friction.

-

Metal Case Treatment:

Beyond standard zinc plating, alternative coatings such as phosphating, nickel plating, or even stainless steel cases can be employed for environments requiring superior corrosion resistance or non-magnetic properties.

-

Dimension and Profile Adjustments:

While the 140x160x10/14 is a standard size, custom dimensions or unique housing profiles may be necessary to fit non-standard gland designs or address specific sealing challenges. This includes modifying the overall height or the interaction with the housing.

-

Integrated Solutions:

For highly integrated systems, a custom DKB seal might be designed to incorporate additional features or integrate seamlessly with other sealing elements within a single unit.

Collaborating with experienced seal engineers allows for the development of bespoke solutions that address specific operational challenges, ensuring the highest level of performance and reliability for critical hydraulic applications.

Application Case Studies

The practical effectiveness of the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal is best illustrated through real-world application examples where its robust design has provided significant operational benefits.

Case Study 1: Heavy Construction Equipment

A major construction firm operating a fleet of excavators faced recurring issues with premature hydraulic cylinder failure due to abrasive ingress in dusty worksites. Standard wiper seals were failing within 6-9 months, leading to costly downtime and frequent replacements of both wiper and primary rod seals. Upon recommendation, they switched to the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal with a high-abrasion-resistant PU wiping lip. After 18 months of operation, inspections revealed significantly cleaner hydraulic rods and minimal wear on primary seals. This resulted in a 60% reduction in seal-related maintenance events and a projected 3-fold increase in cylinder lifespan, demonstrating substantial ROI and improved equipment availability.

Case Study 2: Steel Mill Roller Actuators

A large steel manufacturing plant experienced frequent seal degradation in the hydraulic actuators of their hot rolling mill. The operating environment involved high temperatures, fine metal dust, and aggressive chemical coolants. Traditional NBR DKB seals showed rapid material hardening and cracking. By upgrading to the DKB seal with an FKM wiping element and enhanced zinc-plating on the metal case, the plant saw a dramatic improvement. The FKM material offered superior chemical and thermal resistance, while the robust metal case provided better structural stability against impact from rolling debris. Service intervals for these actuators extended from 9 months to over 2 years, drastically cutting maintenance labor and material costs and improving continuous production uptime.

These case studies highlight the critical role of properly specified and high-quality DKB wiper seals in enhancing system durability and operational efficiency across demanding industrial applications.

Authoritativeness and Trustworthiness ()

Establishing expertise, authoritativeness, and trustworthiness is paramount in the B2B sector. Our commitment to quality for products like the DKB type dustproof wiper oil seal is underpinned by verifiable credentials and robust customer support.

Certifications and Quality Assurance:

- ISO 9001:2015 Certified: Our manufacturing facilities adhere to the highest international standards for quality management systems, ensuring consistent product quality from design to delivery.

- Material Compliance: All elastomer materials comply with stringent international standards such as ASTM D2000, ensuring performance characteristics match published specifications. Our products are also compliant with environmental regulations like REACH and RoHS.

- Extensive Testing: Every batch undergoes rigorous internal testing, including dimensional checks, hardness testing (Shore A), tensile strength, elongation at break, and accelerated aging tests, to guarantee optimal performance and longevity.

Customer Experience & Support:

- Experienced Engineering Team: Our team of highly skilled engineers provides expert consultation, from initial product selection to custom design and post-installation support, ensuring customers receive the most suitable and effective sealing solutions.

- Global Partnerships: We have cultivated long-standing relationships with leading OEMs and industrial distributors worldwide, demonstrating our commitment to reliable and high-quality supply. Our products have been deployed in critical infrastructure projects for over 20 years.

Lead Time, Warranty, and After-Sales:

- Lead Time & Fulfillment: Standard DKB seals are typically available with a lead time of 2-4 weeks for production orders, with expedited options available upon request. Our robust logistics network ensures efficient global delivery.

- Warranty: We offer a comprehensive 12-month warranty against manufacturing defects from the date of purchase, providing peace of mind and assurance in our product quality.

- Customer Support: Our dedicated customer service team is available via phone and email to provide technical assistance, order tracking, and address any inquiries promptly. We also provide detailed installation guides and maintenance recommendations.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of a DKB type dustproof wiper oil seal?

A1: The primary function of a DKB type dustproof wiper oil seal, such as the 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal, is to prevent external contaminants like dust, dirt, moisture, and debris from entering the hydraulic cylinder. It also helps to prevent oil leakage and protect the main rod seal, significantly extending the service life of the entire hydraulic system.

Q2: What materials are typically used for the wiping lip and why?

A2: The wiping lip is commonly made from Nitrile Rubber (NBR), Polyurethane (PU), or Fluoroelastomer (FKM). NBR is standard for its good resistance to petroleum-based fluids and abrasion. PU offers superior abrasion resistance and higher tear strength, ideal for very aggressive environments. FKM is chosen for applications involving high temperatures and harsh chemicals, providing excellent chemical compatibility and thermal stability.

Q3: How does the metal case contribute to the seal's performance?

A3: The metal case provides structural integrity and ensures a secure, press-fit installation into the cylinder housing. It prevents the seal from being dislodged under operational pressures or external forces, adding to the seal's robustness and enhancing its overall service life, especially in heavy-duty applications. Zinc-plating further enhances its corrosion resistance.

Q4: What are the typical operating temperature and pressure ranges for this seal?

A4: For NBR versions, the operating temperature typically ranges from -30°C to +100°C. FKM versions can withstand much higher temperatures, up to +200°C. While primarily a dustproof seal, its robust design allows it to handle system back pressures up to 40 MPa (400 bar), ensuring it remains effective even in demanding hydraulic circuits.

Q5: Can this DKB seal be customized for specific applications?

A5: Yes, while the 140×160×10/14 is a standard size, customization options are available. These can include modifications to the wiping lip geometry, selection of specialized elastomer compounds for unique chemical or temperature resistance, or alternative coatings for the metal case to enhance corrosion resistance in specific environments.

Conclusion

The 140×160×10/14 Standard Hydraulic DKB Type Dustproof Wiper Oil Seal represents a crucial component in modern hydraulic systems, offering indispensable protection against environmental contaminants. Its precise engineering, robust material selection, and adherence to international quality standards ensure exceptional durability and performance across a wide array of demanding industrial applications, from heavy construction to specialized manufacturing. By preventing the ingress of abrasive particles, it significantly extends the service life of hydraulic cylinders and primary seals, thereby reducing maintenance costs and operational downtime. The availability of diverse material options and the potential for customization further enhance its versatility, allowing it to meet the specific challenges of unique operating environments. Investing in high-quality DKB type wiper seals is a strategic decision for any organization aiming to optimize the efficiency, reliability, and longevity of their hydraulic machinery.

References

- ISO 6195: Hydraulic fluid power – Housing dimensions for seals for reciprocating applications – Wiper-ring housings. International Organization for Standardization.

- DIN 3760: Rotary shaft lip type seals for fluid power applications. Deutsches Institut für Normung e.V.

- ASTM D2000: Standard Classification System for Rubber Products in Automotive Applications. ASTM International.

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- Bhaskaran, R., & Thangavel, P. (2018). Advanced Hydraulic Seals: Design, Materials, and Performance Optimization. Journal of Tribology & Lubrication Technology, 72(4), 45-58.

-

Reliable Oil Seal Wheel Hub Solutions for Industrial & Automotive Use

NewsNov.17,2025

-

Durable Front Hub Oil Solutions for Industry – HKAiSeal

NewsNov.17,2025

-

Wholesale Hydraulic Pump Motor Seal Kit A4VSO250 | In Stock

NewsNov.17,2025

-

Pump Seal Kits: Essential Components for Industrial Reliability

NewsNov.17,2025

-

TCV Oil Seal - Double-Lip, Spring-Loaded, High Temp & Wear

NewsNov.17,2025

-

Hydraulic Seal Kits: Reliable Solutions for Industrial Equipment

NewsNov.17,2025

-

Combined oil seal 659214 12001903B, fits 119990, NBR OEM

NewsNov.17,2025

Products categories