- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Inggeris

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Melayu

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dis . 23, 2024 14:46 Kembali kepada senarai

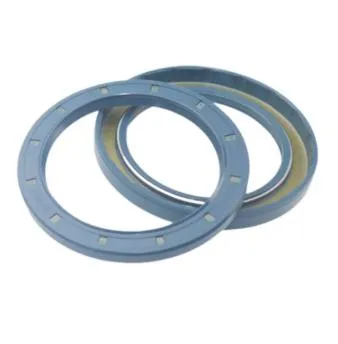

Characteristics and Applications of High Pressure Hydraulic Shaft Seals

High pressure hydraulic shaft seals are widely used sealing components in mechanical equipment, whose main function is to prevent lubricant or liquid leakage and resist the invasion of external pollutants. The design and manufacturing technology of high-pressure oil seals are constantly advancing with the development of industry, and their characteristics and applications are also showing a diversified trend.

Several notable features of high pressure hydraulic shaft seals are worth paying attention to

Firstly, pengedap minyak tekanan tinggi use high-quality materials such as fluororubber, hydrogenated nitrile rubber, etc. These materials have good oil resistance, temperature resistance, and chemical corrosion resistance, and can work normally in high temperature and high pressure environments. Secondly, the structural design of high-pressure oil seals usually includes parts such as springs, inner rings, and outer rings, where the springs can generate appropriate pressure to ensure stable sealing performance. In addition, the wall thickness and sealing lip shape design of the meterai tekanan tinggi have been carefully calculated to achieve the best sealing effect. These characteristics enable high-pressure oil seals to effectively maintain the operational stability of equipment under complex working conditions.

The application fields of high pressure hydraulic shaft seals are very extensive

Firstly, in the automotive industry, pengedap minyak tekanan tinggi are important sealing components for engines, transmissions, and other parts, which can effectively prevent lubricant leakage and improve the performance and lifespan of automobiles. In addition, in hydraulic and pneumatic equipment, such as hydraulic cylinders and air cylinders, high-pressure oil seals also play a crucial role in ensuring effective transmission of liquids or gases and preventing leaks. In addition, high-pressure oil seals are becoming increasingly common in fields such as mechanical manufacturing, aerospace, petrochemicals, and food processing. In these applications, oil seal high pressure not only improves equipment safety, but also reduces maintenance and replacement costs, enhancing overall economic benefits.

Overall, high-pressure oil seals play an indispensable role in multiple industrial fields due to their unique material properties and structural design. With the advancement of technology, the performance of high-pressure oil seals will continue to improve in the future, and their application scope will become more extensive, providing guarantees for the efficient operation of various mechanical equipment.

-

Eaton 5423 6423 Motor Repair Seal Kit: Premium Quality & Fit

BeritaAug.29,2025

-

25x47x7 High Quality Tcv Oil Seal for Hydraulic Pump

BeritaAug.28,2025

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

BeritaAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

BeritaAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

BeritaAug.13,2025

-

Skeleton Oil Seal with NBR Material

BeritaAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

BeritaAug.13,2025

Kategori produk