മാര് . 05, 2025 06:25 Back to list

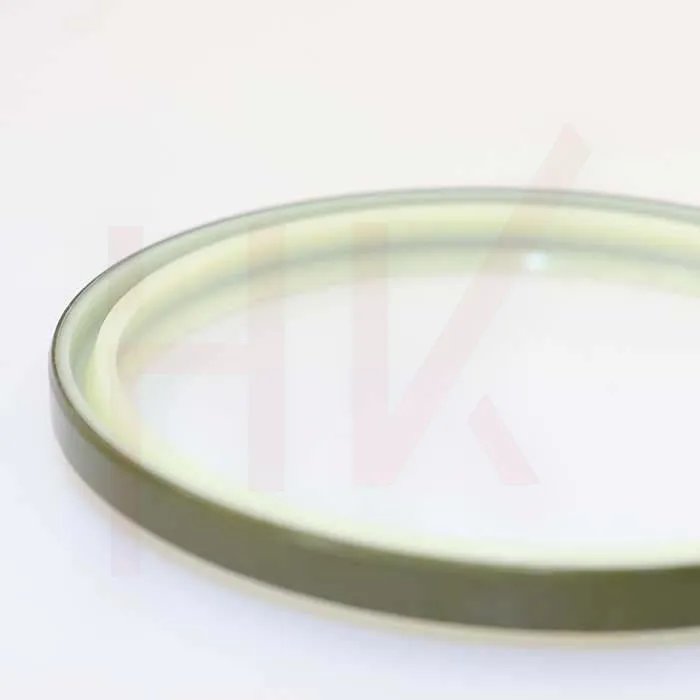

185*205*11 Rubber Oil Seal From Tcv NBR FKM High Pressure Oil Seal Tcv Oil Seal

Authoritativeness in the discussion of oil seals is best demonstrated through referencing industry standards and certifications. Reputable manufacturers often adhere to standards such as the ISO 6194, which outlines the testing and specification criteria for rotary shaft lip-type seals. These standards ensure that the 14x24x6 oil seals meet rigorous quality and performance benchmarks, giving assurance to engineers and procurement managers of their reliability and durability. Authoritative bodies like the International Organization for Standardization and various mechanical engineering institutions provide a framework that manufacturers follow, solidifying trust in their products. Trustworthiness is paramount when selecting components for critical machinery. Reliable vendors of the 14x24x6 oil seal often document detailed product data sheets, including the seal's material properties, recommended applications, and compatibility with various lubricants. These documents serve as a testament to the manufacturer's transparency and commitment to quality, fostering trust among consumers. User testimonials and case studies further bolster the credibility of these products, offering real-world insights into the seal's performance in various applications, from automotive to industrial machinery. In conclusion, understanding the 14x24x6 oil seal requires a confluence of practical experience, technical expertise, authoritative standards, and trust in supplier commitments. By selecting the right seal with these factors in mind, machinery operators can ensure longer-lasting, efficient operations, minimizing potential failures while enhancing productivity. The importance of these seals cannot be overstated in industries where precision and reliability dictate success, making technical insights and informed choices critical in the realm of mechanical maintenance and engineering.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories