Mar . 04, 2025 02:21 Back to list

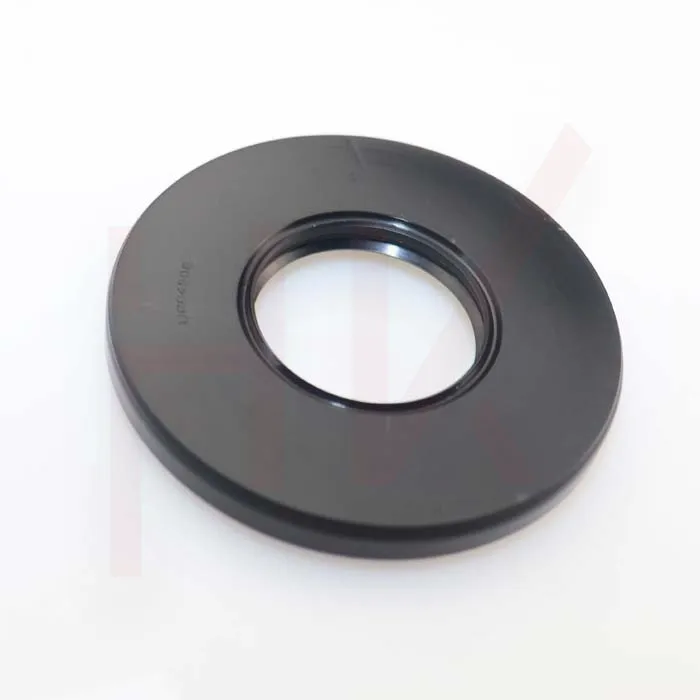

metal cased oil seals

Trust in the efficacy of metal-cased oil seals stems from rigorous testing and industry standards adherence. Manufacturers conduct exhaustive assessments, replicating real-world stressors to ensure that seals perform flawlessly under specified conditions. This dedication to quality control bolsters user confidence, as equipment operators can depend on these seals to prevent costly leaks and environmental contamination. Enhancing the appeal of metal-cased oil seals is their adaptability across various applications. Whether in automotive transmissions or industrial pumps, they are designed to fit seamlessly, maintaining fluid integrity and minimizing wear and tear. Additionally, their compatibility with automatic assembly processes enhances efficiency in high-volume manufacturing environments, a critical factor for original equipment manufacturers (OEMs). The growing emphasis on sustainability further amplifies the relevance of high-quality oil seals. By preventing leaks, they contribute to a reduction in oil consumption and waste, aligning with broader environmental goals. Experts in the field predict a continuous evolution of seal technology, with innovations aimed at improving efficiency and reducing ecological impact, thus playing a crucial role in the transition towards greener industrial practices. To sum up, metal-cased oil seals embody a blend of technical excellence and practical utility, making them indispensable in modern machinery. Their proven reliability and adaptability address the multifaceted challenges faced in equipment maintenance, delivering performance that industry professionals rely on. For businesses keen on optimizing machinery lifespan and operational efficiency, investing in high-quality metal-cased oil seals is a decision backed by expertise, authority, and unwavering trust.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories