oct. . 10, 2024 04:25 Back to list

what is the purpose of oil seal

The Purpose of an Oil Seal A Vital Component in Machinery

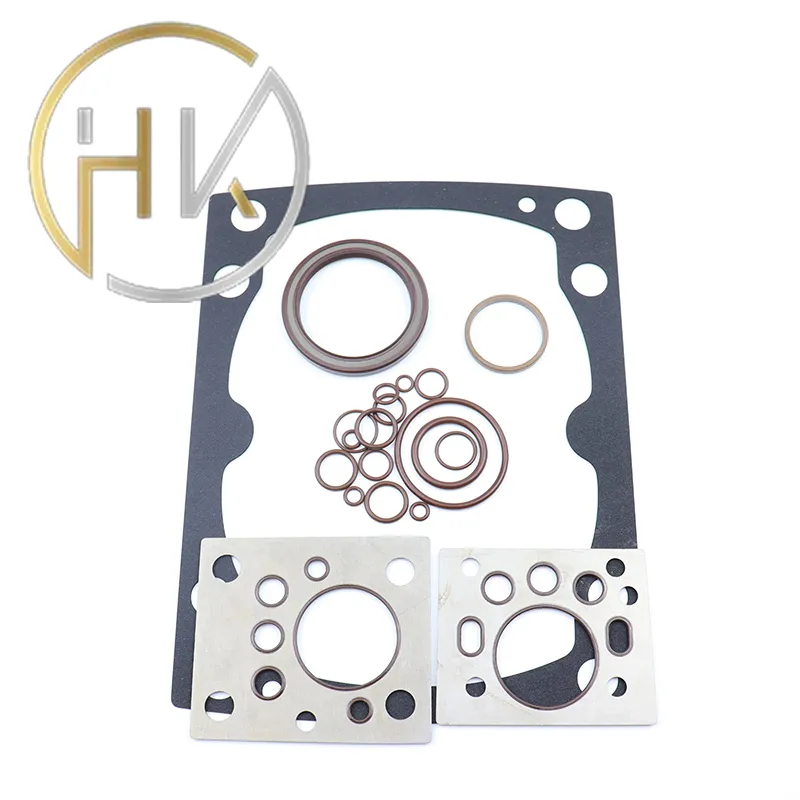

In the realm of mechanical engineering and machinery, the oil seal is an understated hero that plays a crucial role in maintaining the integrity and efficiency of various systems. An oil seal, also known as a shaft seal or grease seal, is a device that is intended to prevent the leakage of lubricants, such as oil or grease, from rotary shafts while keeping contaminants, like dirt and moisture, from entering the machinery. This article will explore the purpose of oil seals, their construction, types, and significant benefits in various applications.

The Purpose of an Oil Seal A Vital Component in Machinery

Additionally, oil seals serve to keep contaminants out of the internal components of machinery. Dust, dirt, and moisture can severely damage the internal workings of mechanical systems. An effective oil seal creates a protective barrier that prevents these harmful substances from entering the system, thereby preserving the integrity of the lubricant and the machinery.

what is the purpose of oil seal

Oil seals are typically constructed from elastomeric materials, such as rubber or synthetic compounds, which allow them to create a tight seal against the surface of a rotating shaft. This flexibility is crucial as it allows the oil seal to adapt to slight changes in temperature and movement, ensuring continued protection against leakage and contamination. The design of oil seals includes various features, such as a sealing lip, which makes contact with the shaft to create a dynamic seal, and a rigid outer casing that fits snugly into the housing.

There are several types of oil seals designed for specific applications. The most common types include radial oil seals, which are used in applications where the shaft rotates, and axial oil seals, designed for static applications or where there is little movement. Additionally, specialized oil seals are created for high-temperature or high-pressure environments, further enhancing their versatility in various industrial settings.

The benefits of using oil seals in industrial machinery are manifold. First, they help to significantly reduce maintenance costs by minimizing lubricant loss and preventing the ingress of contaminants, which can lead to costly downtime and repairs. Second, oil seals contribute to energy efficiency by ensuring that machinery operates smoothly and without excessive friction, thereby reducing energy consumption. Lastly, by prolonging the life of machinery components through effective sealing, oil seals contribute to sustainability by reducing the need for replacements and minimizing waste.

In conclusion, the oil seal plays an essential role in the functionality and longevity of mechanical systems. By containing lubricants and shielding internal components from contaminants, oil seals enhance performance, reduce maintenance costs, and contribute to the overall sustainability of machinery. Understanding the purpose and importance of oil seals is indispensable for anyone involved in the maintenance and operation of mechanical systems, as they are a cornerstone of reliable and efficient machinery operation.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories