juny . 06, 2025 09:13 Tornar a la llista

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

The world of hydraulic systems is evolving rapidly, and at the heart of this transformation are advanced sealing solutions like the segell d'oli hidràulic, particularly the TCN oil seal. These innovations are not just improving efficiency but are also integrating cutting-edge IoT technology to redefine performance monitoring and maintenance.

Understanding Hydraulic Oil Seal and TCN Type Oil Seal

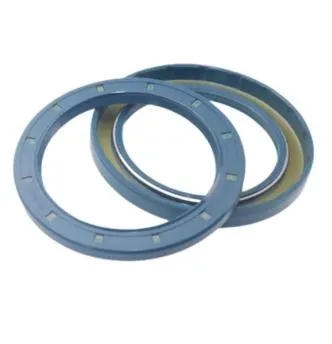

A segell d'oli hidràulic is a critical component designed to prevent fluid leakage and contamination in hydraulic systems. Among the various types, the TCN oil seal stands out due to its unique design, which ensures superior sealing performance under high-pressure conditions. The TCN type oil seal features a triple-lip structure, offering enhanced durability and resistance to wear.

The oil seal TCN variant is widely used in heavy machinery, automotive systems, and industrial hydraulics due to its ability to withstand extreme temperatures and pressures. With IoT integration, these seals are now smarter, providing real-time data on wear and tear, enabling predictive maintenance, and reducing downtime. This advancement is revolutionizing how industries manage their hydraulic systems.

The Role of Modern Hydraulic Oil Seals

The integration of IoT technology into hydraulic oil seals, especially the TCN oil seal, marks a significant leap forward. Smart sensors embedded within the seals monitor parameters such as pressure, temperature, and friction levels. This data is transmitted to centralized systems, allowing engineers to detect potential failures before they occur.

For instance, a TCN type oil seal equipped with IoT capabilities can alert operators when lubrication levels are low or when abnormal vibrations are detected. This proactive approach minimizes unexpected breakdowns, extends seal lifespan, and optimizes hydraulic system performance. Wholesalers distributing these advanced seals can offer their clients a competitive edge by reducing maintenance costs and improving operational efficiency.

Furthermore, the integration of IoT in TCN type oil seals facilitates predictive maintenance. By analyzing real-time data on seal performance and wear, maintenance teams can schedule repairs and replacements before minor issues escalate into costly downtimes. This predictive capability not only enhances the reliability of hydraulic systems but also boosts the overall productivity of machinery in various industries, ranging from automotive to aerospace.

Benefits of Upgrading to Smart Hydraulic Oil Seals Solutions

Switching to IoT-enabled oil seal TCN products brings numerous advantages. First, it enhances reliability by providing continuous monitoring, ensuring that hydraulic systems operate at peak efficiency. Second, it reduces maintenance expenses by replacing reactive repairs with predictive interventions. Third, the data collected helps in refining seal designs for even better performance in the future.

Fourth, IoT-enabled oil seal TCN products offer real-time diagnostics, allowing for quicker identification and resolution of issues before they escalate into more significant problems. Fifth, the integration with smart systems facilitates easier tracking and management of inventory, optimizing resource allocation and reducing downtime. Sixth, these products contribute to enhanced safety by monitoring for potential leaks or failures, thereby mitigating risks associated with hydraulic system malfunctions.

For wholesalers, promoting these next-generation hydraulic oil seals means tapping into a growing market of industries seeking smarter, more efficient solutions. By offering TCN oil seals with IoT features, distributors can position themselves as leaders in hydraulic innovation, attracting clients who prioritize long-term cost savings and system reliability.

FAQ: Hydraulic Oil Seals

What makes the TCN oil seal different from standard hydraulic oil seals?

The TCN type oil seal features a triple-lip design, providing better sealing efficiency and durability compared to conventional single or double-lip seals. Its construction ensures superior performance in high-pressure and high-temperature environments, making it ideal for demanding hydraulic applications.

How does IoT integration improve the functionality of hydraulic oil seals?

IoT-enabled TCN oil seals incorporate sensors that track real-time performance metrics. This allows for predictive maintenance, reducing unexpected failures and extending the lifespan of both the seal and the hydraulic system. The data collected also helps optimize operational conditions for better efficiency.

Are smart hydraulic oil seals cost-effective for industrial use?

Yes. While the initial investment may be higher, the long-term savings from reduced downtime, lower maintenance costs, and extended equipment life make IoT-integrated oil seal TCN solutions highly cost-effective for industries relying on hydraulic systems.

Can hydraulic oil seals be customized for specific applications?

Absolutely. Manufacturers can tailor TCN oil seals to meet unique operational requirements, including variations in size, material, and IoT sensor configurations. This ensures optimal performance across diverse industrial applications.

Why should wholesalers prioritize promoting smart hydraulic oil seals?

Wholesalers who offer IoT-integrated oil seal TCN products can differentiate themselves in a competitive market. These advanced solutions meet the growing demand for smart, efficient, and reliable hydraulic components, attracting forward-thinking clients and fostering long-term business growth.

The future of hydraulic sealing lies in smart, IoT-integrated solutions like the TCN oil seal. By upgrading to these advanced hydraulic oil seals, industries can achieve unparalleled efficiency, reliability, and cost savings. Wholesalers play a pivotal role in driving this innovation—partner with us today to supply cutting-edge oil seal TCN products and lead the market in hydraulic sealing technology. Place your orders now and be at the forefront of this transformative shift!

-

The Trans-formative Journey of Wheel Hub Oil Seals

NotíciesJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NotíciesJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NotíciesJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NotíciesJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NotíciesJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NotíciesMay.22,2025

-

Reliable High-Pressure Oil Seals for Industrial Efficiency

NotíciesMay.22,2025

Categories de productes