nov. . 15, 2024 16:12 Back to list

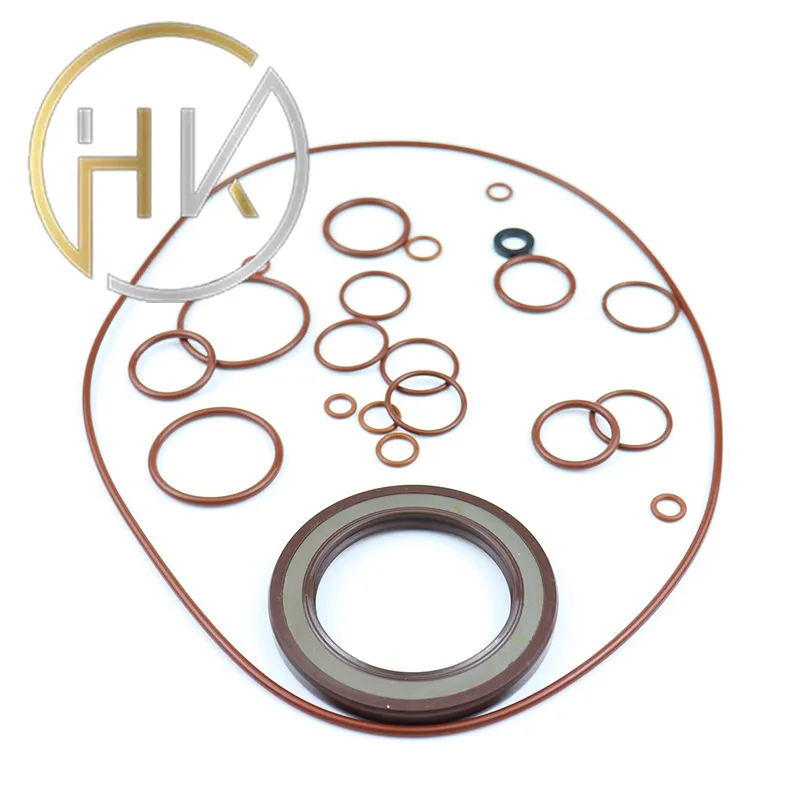

high temperature o ring kit

Understanding High Temperature O-Ring Kits Applications and Benefits

O-rings are essential components used in various industrial applications for sealing purposes. They are circular rings made of elastomeric materials that prevent the leakage of fluids and gases. Among the diverse types of O-rings available, high-temperature O-ring kits have gained prominence due to their ability to withstand extreme conditions. This article explores high-temperature O-ring kits, their composition, applications, and the benefits they provide.

What are High Temperature O-Ring Kits?

High-temperature O-ring kits are specially designed collections of O-rings that can operate effectively at elevated temperatures. Standard O-rings often fail under high-heat environments, where material degradation, loss of elasticity, and premature failure can occur. High-temperature O-rings, however, are crafted from advanced materials, such as fluorocarbon (FKM), silicone (VMQ), perfluoroelastomers (FFKM), and other specialized compounds, allowing them to endure temperatures exceeding 200°C (392°F) and sometimes even higher.

Applications of High Temperature O-Ring Kits

High-temperature O-ring kits find applications across various industries due to their robust performance characteristics

1. Automotive Industry In automotive engines, high-temperature O-rings are used in applications such as oil seals, fuel systems, and coolant passages, where exposure to heat and aggressive fluids is common.

2. Aerospace The aerospace sector demands components that can withstand extreme temperatures and pressures. High-temperature O-rings are used in fuel systems, hydraulic systems, and cabin pressure seals.

3. Chemical Processing Chemical reactors often operate at high temperatures and involve corrosive fluids. O-rings made from materials resistant to chemical attack ensure system integrity.

4. Oil and Gas Exploration and production equipment in oil and gas frequently encounter high-temperature environments. O-rings help in sealing connections in drilling equipment, valves, and pumps, preventing leaks.

high temperature o ring kit

5. Food and Pharmaceutical In processes requiring sterilization or where strict hygiene standards are in place, high-temperature O-rings made from FDA-approved materials are used in sealing applications.

Benefits of Using High Temperature O-Ring Kits

1. Enhanced Performance The primary benefit of high-temperature O-rings is their ability to maintain sealing properties even under extreme conditions. This results in reduced risk of leaks and improved operational efficiency.

2. Longevity High-temperature O-rings are engineered to resist thermal degradation, which extends their lifespan compared to standard O-rings. This longevity translates to less frequent replacements and lower maintenance costs.

3. Versatility With various materials available in high-temperature O-ring kits, users can select the right type that suits their specific application needs, including resistance to chemicals, abrasions, and extreme temperature fluctuations.

4. Cost-Effectiveness While high-temperature O-ring kits may have a higher upfront cost than standard kits, their durability and performance under challenging conditions contribute to overall cost savings in the long run by minimizing breakdowns and maintenance.

5. Safety In many applications, effective sealing is crucial for safety. High-temperature O-rings help prevent leaks that could lead to dangerous situations, protecting both equipment and personnel.

Conclusion

High-temperature O-ring kits are indispensable in modern industrial applications requiring reliable sealing solutions. By understanding their composition, applications, and benefits, industries can choose the right O-rings that enhance performance and safety while reducing maintenance costs. As technology continues to advance, the development of new materials for high-temperature O-rings promises even better performance and broader applications, paving the way for more efficient and safe operating environments.

Investing in high-temperature O-ring kits is a wise choice for businesses looking to improve the reliability and effectiveness of their systems in demanding conditions. With the right O-ring, industries can ensure they are well-equipped to handle high temperatures and the challenges that come with them.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories