des. . 24, 2024 11:40 Back to list

Comparison of Dust Seals and Oil Seals for Optimal Performance in Machinery

Understanding Dust Seals vs. Oil Seals An In-depth Comparison

In the realm of mechanical engineering and maintenance, seals play a vital role in ensuring the efficiency and longevity of machinery and equipment. Among these, dust seals and oil seals are two essential components that serve distinct purposes. Understanding their differences, functions, and applications is crucial for anyone involved in the maintenance of machinery.

What is a Dust Seal?

Dust seals are primarily designed to protect machinery from dirt, dust, and debris. They act as barriers, preventing particulate matter from entering sensitive areas of machinery, such as bearings, gears, and hydraulic systems. Dust seals are commonly made from flexible materials like rubber or polyurethane, which can adequately deform to accommodate dust particles of various sizes.

One of the key features of dust seals is their ability to maintain a tight fit without needing to create significant pressure differentials. They may not provide the same level of fluid containment as oil seals, but their primary function is to keep contaminants at bay. This is particularly important in environments where dirt and debris are prevalent, such as construction sites or manufacturing plants.

What is an Oil Seal?

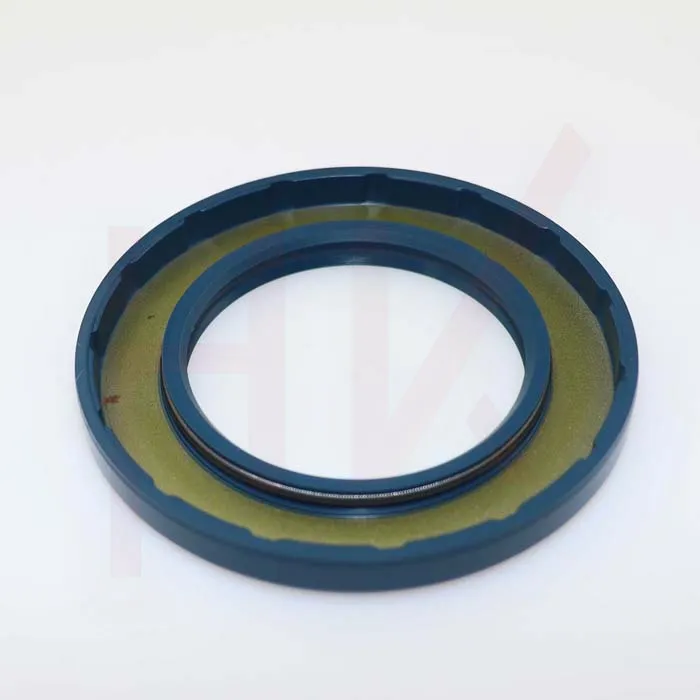

Oil seals, on the other hand, are designed to contain lubricating oils within machinery. These seals prevent oil from leaking out and, at the same time, stop contaminants from entering. Unlike dust seals, oil seals are tailored to handle the pressure generated within a system and provide a much tighter and more reliable seal against fluids. Often constructed from materials like Nitrile rubber or Fluoroelastomer, oil seals are built to withstand challenges like temperature fluctuations and the corrosive nature of certain oils.

The design of oil seals typically includes a dynamic lip that creates a seal against a rotating shaft, effectively preventing oil leaks while allowing for smooth movement. This dynamic sealing action is crucial in maintaining lubrication in various systems, including engines, gearboxes, and hydraulic applications.

dust seal vs oil seal

Key Differences Between Dust Seals and Oil Seals

The primary distinction between dust seals and oil seals lies in their purpose and functionality. Dust seals focus on preventing dry contaminants from entering a machinery compartment, whereas oil seals are meant to keep lubricants contained and protect against fluid loss.

Another significant difference is the design and construction materials used. Dust seals can often be simpler in design and do not require the robust sealing performance that oil seals necessitate. In contrast, oil seals must manage pressure differences and thus need to be constructed from more durable materials that can withstand the conditions of the environment in which they operate.

Applications

Both seals find their application in various sectors, including automotive, industrial machinery, and consumer electronics. Dust seals are often utilized in wheel bearings, industrial fans, and machinery exposed to harsh environments. Oil seals, however, are predominantly employed in applications requiring oil retention, such as automotive engines, hydraulic cylinders, and gearboxes.

Conclusion

In conclusion, both dust seals and oil seals play vital roles in maintaining the integrity and functional performance of machinery. Understanding the differences between them allows engineers and technicians to choose the appropriate seal for specific applications, ensuring optimal performance and longevity. Whether protecting against the intrusion of dust or containing valuable lubricants, the right seal makes all the difference in the efficiency and reliability of mechanical systems.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories