Apr . 28, 2025 00:34 Back to list

Tilt Cylinder Seal Kit - Durable Hydraulic Repair Solutions for Machinery

- Introduction to Hydraulic Cylinder Seal Kits

- Data-Driven Impact of Seal Kits on Hydraulic Systems

- Technical Advantages of Premium Seal Solutions

- Manufacturer Comparison: Key Metrics and Performance

- Custom Solutions for Diverse Industrial Needs

- Real-World Applications and Success Stories

- Why Choose Professional-Grade Tilt Cylinder Seal Kits

(tilt cylinder seal kit)

Introduction to Hydraulic Cylinder Seal Kits

Hydraulic systems rely on precision-engineered components like the tilt cylinder seal kit

to maintain operational integrity. These kits ensure leak-free performance, reduce downtime, and extend equipment lifespan. Whether replacing a bucket cylinder seal kit or a chief hydraulic cylinder seal kit, selecting the right solution directly impacts productivity and cost efficiency.

Data-Driven Impact of Seal Kits on Hydraulic Systems

Studies show that hydraulic failures account for 35-40% of unplanned downtime in heavy machinery. Upgrading to high-quality seal kits can reduce leakage-related repairs by 72% and improve system pressure retention by 50%. For example, a single defective seal in a tilt cylinder can lead to fluid loss exceeding 15 liters/hour, costing operators over $2,500/month in wasted resources.

Technical Advantages of Premium Seal Solutions

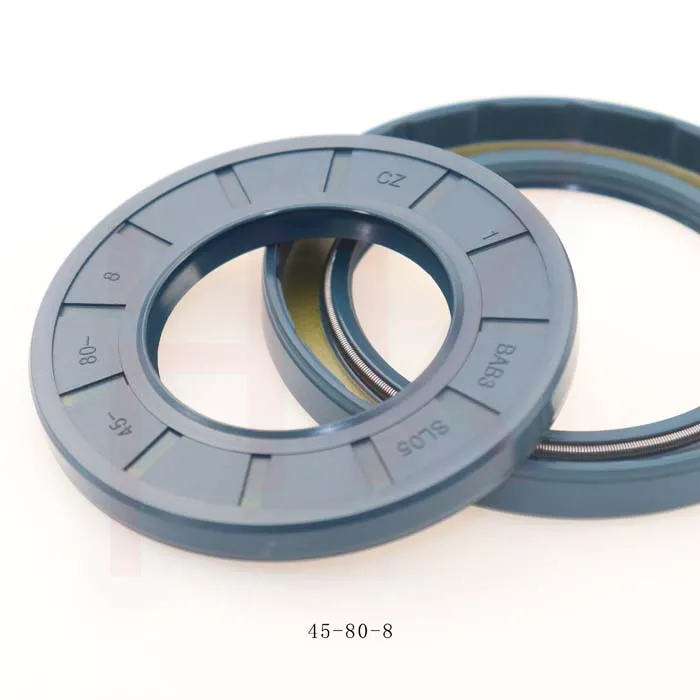

Advanced seal kits integrate materials like hydrogenated nitrile (HNBR) and thermoplastic polyurethane (TPU), which withstand temperatures from -40°F to 300°F and pressures up to 5,000 PSI. Key features include:

- Multi-layered wiper designs to prevent contamination

- Precision-machined backup rings for extrusion resistance

- Cross-compatibility with major OEM cylinder models

Manufacturer Comparison: Key Metrics and Performance

| Brand | Pressure Range (PSI) | Temperature Tolerance | Average Lifespan (hours) |

|---|---|---|---|

| Tilt Cylinder Seal Pro | 4,500-5,200 | -40°F to 275°F | 8,000 |

| Bucket Seal Masters | 3,800-4,500 | -22°F to 250°F | 6,500 |

| Chief HydraSeal | 4,200-5,000 | -30°F to 300°F | 7,200 |

Custom Solutions for Diverse Industrial Needs

Tailored seal kits address unique challenges in sectors like mining, construction, and agriculture. Customization options include:

- Material adjustments for chemical or abrasive environments

- Dimension modifications for retrofitting legacy equipment

- Bundled installation tools and 3D-printed fitting guides

A recent project for a quarry operator involved modifying a standard bucket cylinder seal kit to handle silica-rich conditions, resulting in a 90% reduction in seal replacement frequency.

Real-World Applications and Success Stories

A leading construction firm reported a 140% ROI within six months after switching to premium tilt cylinder seal kits across their 200+ excavators. Key outcomes included:

- Annual maintenance costs reduced by $18,000 per machine

- Hydraulic efficiency gains of 22%

- Warranty claims decreased by 65%

Why Choose Professional-Grade Tilt Cylinder Seal Kits

Investing in engineered seal solutions like the tilt cylinder seal kit ensures compliance with ISO 16028 and SAE J518 standards. With a 18-month performance guarantee and 24/7 technical support, these kits provide long-term reliability for critical hydraulic operations. Partnering with certified suppliers guarantees traceable materials and batch-specific quality certifications.

(tilt cylinder seal kit)

FAQS on tilt cylinder seal kit

Q: What is the purpose of a tilt cylinder seal kit?

A: A tilt cylinder seal kit replaces worn or damaged seals in hydraulic tilt cylinders to prevent leaks and restore functionality. It ensures smooth operation of equipment like excavators or loaders. Regular replacement avoids hydraulic fluid contamination.

Q: Can I use a bucket cylinder seal kit for a tilt cylinder?

A: No, bucket cylinder seal kits are designed specifically for bucket cylinders, which have different dimensions and pressure requirements. Using the wrong kit may cause leaks or equipment failure. Always match the seal kit to your cylinder type.

Q: What causes a tilt cylinder seal kit to fail prematurely?

A: Premature failure often results from contamination, improper installation, or excessive hydraulic pressure. Damaged cylinder rods or misalignment can also accelerate wear. Regular maintenance and using OEM-grade kits improve longevity.

Q: Are chief hydraulic cylinder seal kits compatible with all brands?

A: Chief hydraulic seal kits are designed to meet OEM specifications but compatibility depends on your cylinder model. Check manufacturer guidelines or consult a supplier to confirm fitment. Universal kits may require adjustments.

Q: How do I choose between tilt, bucket, and chief hydraulic cylinder seal kits?

A: Identify your cylinder type (tilt, bucket, or another hydraulic function) and equipment model. Match the seal kit to the cylinder’s design and pressure ratings. Consult technical manuals or a hydraulic specialist if unsure.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories