Oct . 22, 2024 12:52 Back to list

high temperature shaft seals

High Temperature Shaft Seals Essential Components for Industrial Machinery

High temperature shaft seals play a crucial role in maintaining the efficiency and reliability of various industrial systems. As machines operate, shafts often rotate at high speeds, leading to potential leaks of fluids, lubricants, or gases. In environments where temperatures soar, traditional sealing solutions can fail, causing detrimental consequences for both equipment and process integrity.

One of the primary functions of high temperature shaft seals is to prevent the escape of lubricants from bearings, which are vital for reducing friction and wear. When temperatures exceed the design limits of standard seals, they can degrade, leading to oil leaks that not only compromise lubrication but can also expose machinery to higher rates of wear and tear. This can ultimately lead to premature failure of components, costly downtimes, and the need for extensive repairs or replacements.

High temperature shaft seals are designed to withstand extreme conditions. These seals are typically constructed from advanced materials such as fluoropolymers and silicone rubber, which exhibit excellent thermal stability and resistance to degradation at elevated temperatures. These materials ensure that the seal maintains its shape and performance over a wide temperature range, often from -100°F to over 600°F (-73°C to 315°C), depending on the specific application requirements.

high temperature shaft seals

In addition to high temperature tolerance, these seals must also possess resistance to chemical exposure. Many industrial processes involve not only high heat but also aggressive chemicals that can break down standard sealing materials. Manufacturers of high temperature shaft seals often incorporate additives or use composite constructions to enhance chemical resistance, thereby extending the lifespan of the seals and reducing maintenance costs.

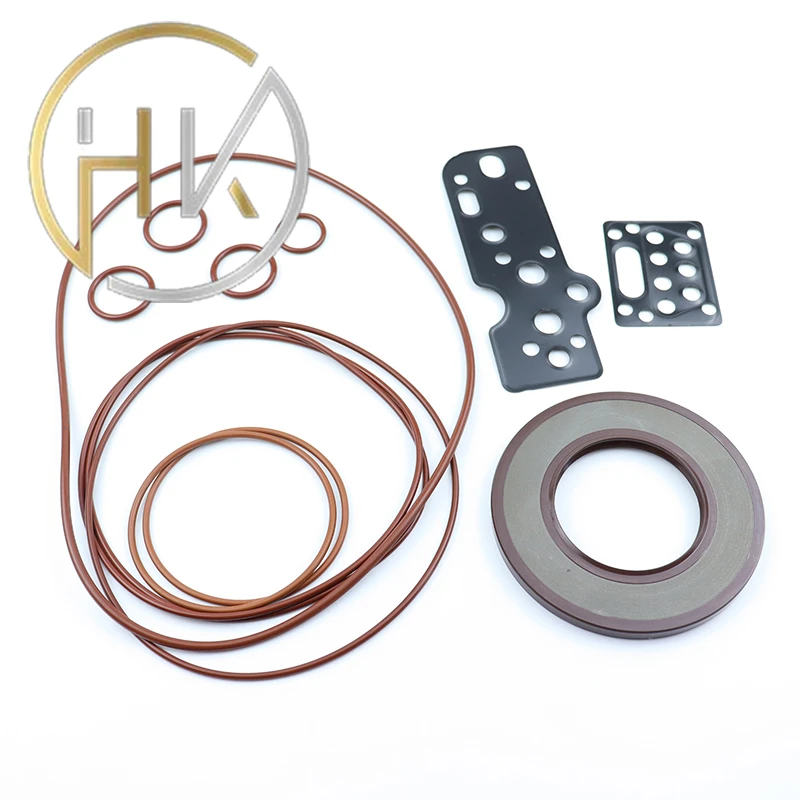

The design of these seals is also a critical factor in their performance. High temperature shaft seals can be configured in various styles, including lip seals, O-rings, and mechanical seals, each offering different advantages for specific applications. For instance, lip seals are commonly used in rotary applications where a dynamic seal is required, while mechanical seals are often employed in pumps and mixers to handle high pressure and temperature variations.

Selecting the right high temperature shaft seal is essential for ensuring optimal performance. Engineers must consider factors such as the operating temperature, speed, pressure, and the type of fluid being sealed. Proper installation is equally important, as misalignment or improper fitting can lead to premature seal failure.

In conclusion, high temperature shaft seals are vital for the effective operation of industrial machinery subjected to elevated temperatures and harsh environments. By utilizing advanced materials and designs, these seals not only enhance the performance and reliability of machines but also contribute to overall operational efficiency by minimizing leaks and reducing maintenance needs. As industries continue to evolve and face more challenging conditions, the importance of robust high temperature shaft seals will only increase, underscoring their role as indispensable components of modern machinery.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories