Nov . 12, 2024 02:05 Back to list

high pressure oil seals suppliers

High Pressure Oil Seals Suppliers Ensuring Reliability in Industrial Applications

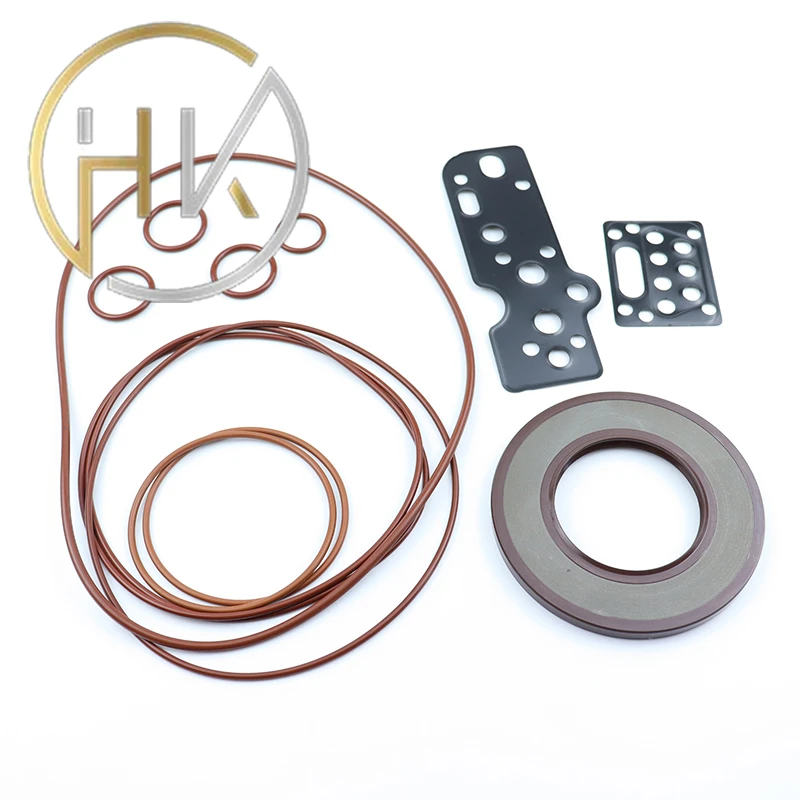

In various industrial applications, the integrity of machinery is paramount. One critical component that contributes to this integrity is the oil seal, especially under high-pressure conditions. High pressure oil seals are designed to prevent the leakage of fluids, protect against contaminants, and enhance the overall performance and longevity of equipment. Therefore, sourcing high-quality high pressure oil seals from reputable suppliers is essential for any industry that relies on machinery and hydraulic systems.

Understanding High Pressure Oil Seals

High pressure oil seals are specialized components that play a crucial role in preventing the escape of oil and other fluids from machinery while keeping dust and debris at bay. These seals are meticulously engineered using advanced materials to withstand extreme temperatures, pressures, and various chemical exposures. Common applications include hydraulic systems, automotive engines, compressors, and heavy machinery, where secure sealing is vital to maintain operational efficiency and safety.

The design of high pressure oil seals typically includes features such as elastomeric materials, metal reinforcement, and specialized lip geometries that ensure optimal sealing performance under dynamic conditions. Choosing the right oil seal is essential to prevent failures that could lead to costly downtimes or catastrophic equipment failures.

The Importance of Choosing the Right Supplier

With a plethora of suppliers available in the market, selecting a reliable high pressure oil seals supplier can be a daunting task

. Several key factors should be taken into consideration1. Quality Assurance Suppliers should provide evidence of compliance with international standards such as ISO 9001, which ensures that they maintain a quality management system. High-quality seals are critical for performance and longevity.

2. Material Expertise Different applications require different materials. A reputable supplier must have a wide range of materials available, such as nitrile rubber (NBR), fluorocarbon (FKM), and polyurethane (PU), to cater to varied operational environments.

high pressure oil seals suppliers

3. Customization Capabilities Industries often have unique sealing requirements. Suppliers who can offer custom-engineered solutions based on specific needs will add immense value to any business.

4. Technical Support A knowledgeable support team can assist in selecting the right seals for particular applications, ensuring that customers make informed decisions.

5. Performance History A supplier with a proven track record in providing high pressure oil seals for reputable brands will give customers confidence in their products.

Leading High Pressure Oil Seals Suppliers in the Market

Several suppliers stand out in the market due to their commitment to quality, innovation, and customer service. Companies like SKF, Parker Hannifin, and Hallite Seals are recognized for their comprehensive range of sealing solutions and their expertise in high pressure applications. They invest heavily in research and development to continuously improve their product offerings and provide clients with the latest sealing technologies.

Additionally, many regional suppliers also excel in providing high-quality seals tailored to local industries. These suppliers often offer enhanced customer service and support, making them attractive options for businesses seeking personalized solutions.

Conclusion

In conclusion, high pressure oil seals are indispensable components that ensure the reliable operation of machinery across various industries. Sourcing these seals from reputable suppliers is critical to maximizing equipment efficiency and longevity. By considering factors such as quality assurance, material expertise, customization capabilities, technical support, and supplier reputation, businesses can make informed decisions that will ultimately protect their investments and improve their operational effectiveness.

As industries evolve and demand higher performance from their machinery, the significance of high pressure oil seals and their suppliers will only continue to grow. In a competitive market where reliability and safety are paramount, businesses must prioritize their choice of suppliers, ensuring they partner with those who deliver quality, innovation, and exceptional service. Ultimately, the right high pressure oil seals supplier can provide a strategic advantage, paving the way for increased productivity and reduced operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories