Jan . 20, 2025 12:38 Back to list

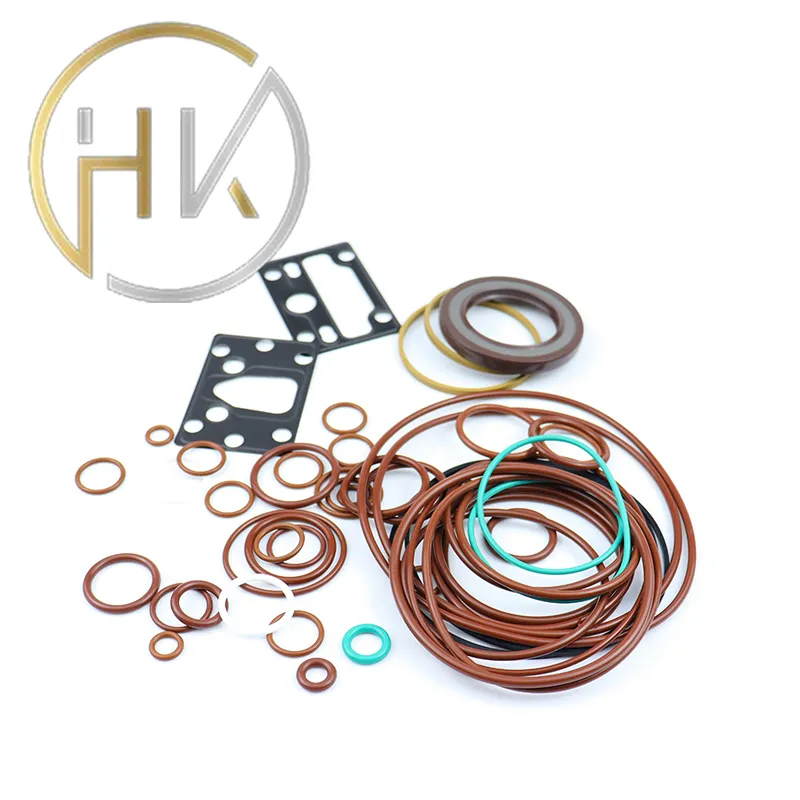

engine hoist hydraulic cylinder rebuild kit

Opting for a rebuild kit provided by the original equipment manufacturer (OEM) is often recommended for those prioritizing reliability and authenticity. OEM kits are specifically designed to meet the performance standards of the original parts, thus ensuring optimal compatibility and functionality. This choice enhances the overall safety and efficiency of the engine hoist and provides peace of mind knowing that the rebuilt cylinder adheres to the manufacturer’s specifications. Alternatively, there are aftermarket kits available, often at a lower cost and sometimes even with enhancements over the original specs. When choosing aftermarket options, ensuring the quality and compatibility of the components is critical. It is wise to rely on reputable brands and user reviews to gauge their performance and reliability. While cost-saving, non-OEM parts should not compromise on quality, as this could lead to failures and safety risks. The process of rebuilding a hydraulic cylinder can also be an opportunity to improve your skills and understanding of machinery maintenance. It not only restores the functionality of the engine hoist but also empowers you to take preventative measures in the future. Knowing how to diagnose issues early, perform inspections, and execute minor repairs can significantly reduce downtime and the need for more costly professional servicing. In conclusion, an engine hoist hydraulic cylinder rebuild kit is a valuable investment for maintaining heavy lifting equipment. Whether you choose OEM or quality aftermarket kits, focusing on quality and detailed workmanship ensures excellent performance and extends the tool's service life. As you embark on the rebuilding process, the experience will also enhance your mechanical aptitude, making you more adept and confident in handling similar tasks in the future.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories