Oct . 13, 2024 20:02 Back to list

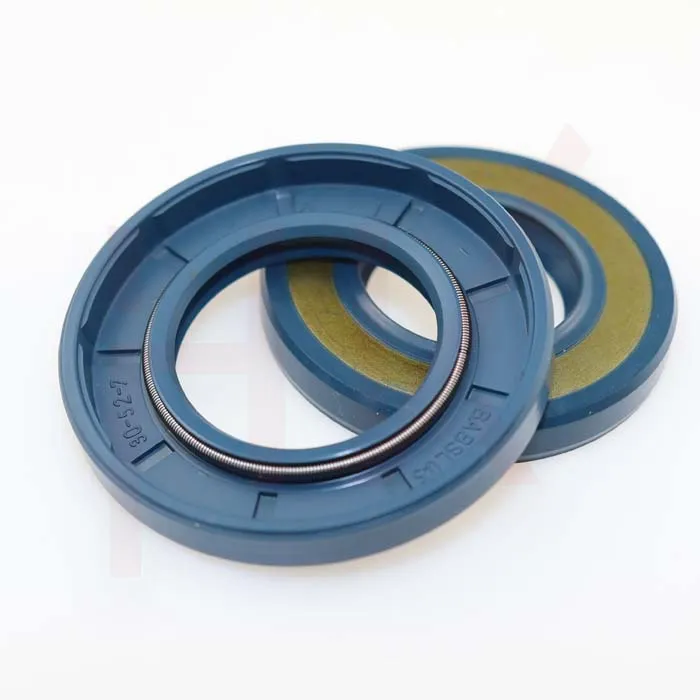

dust proof seal

The Importance of Dust Proof Seals in Modern Applications

In today's world, where technology and machinery play pivotal roles in various industries, maintaining the integrity of equipment is crucial. One of the often-overlooked components that contribute significantly to this is the dust proof seal. These seals are essential for protecting devices and machinery from dust infiltration, ensuring longevity and reliable performance.

Dust is not merely an aesthetic concern; it can have detrimental effects on machinery and electronic devices. In environments that are heavily laden with dust, such as manufacturing plants, construction sites, and even homes, particles can accumulate and cause wear and tear on mechanical parts. This can lead to equipment malfunction, increased maintenance costs, and unexpected downtime, ultimately affecting productivity and safety.

Dust proof seals are engineered to create a barrier against these harmful particles. Typically made from durable materials such as rubber, silicone, or specialized polymers, these seals are designed to fit snugly around various openings in machinery and equipment. Their primary function is to prevent dust, dirt, and other contaminants from entering sensitive areas, such as bearings, motors, and electronic components.

dust proof seal

Moreover, dust proof seals come in various forms, including O-rings, gaskets, and custom shapes tailored to specific applications. The choice of material and design is often influenced by factors such as temperature resistance, chemical compatibility, and the degree of dust exposure the equipment is likely to encounter. For instance, in high-temperature environments, silicone seals may be preferred due to their ability to withstand heat without losing elasticity.

Implementing effective dust proof seals not only enhances the performance of machinery but also extends its operational life. By minimizing wear and protecting critical components, businesses can significantly reduce the frequency of repairs and replacements. This leads to lower operational costs and more efficient use of resources.

Additionally, in the consumer electronics sector, dust proof seals play a vital role in product design. Many smartphones and portable devices come with dust and water resistance ratings, largely thanks to advanced sealing technologies. This not only improves the performance of these gadgets but also enhances consumers' confidence in their durability.

In conclusion, the importance of dust proof seals cannot be understated. As industries continue to evolve and the demand for reliable and resilient machinery grows, investing in high-quality dust proof seals will prove to be a wise choice for both manufacturers and end-users. These small yet mighty components are key to safeguarding equipment, ensuring optimal performance, and ultimately driving success in a competitive marketplace.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories