Nov . 12, 2024 07:59 Back to list

double lip seal

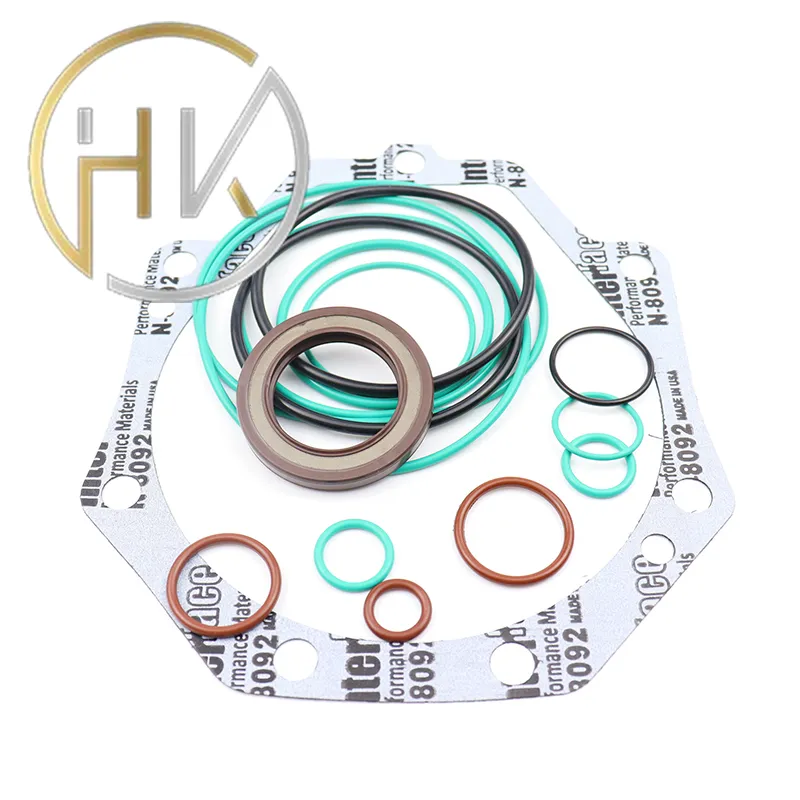

Double Lip Seal An Overview of Its Design and Applications

The double lip seal is a specialized type of sealing mechanism widely used in various industrial applications to enhance performance and durability. This seal is designed to minimize fluid leakage and protect internal components from contaminants, making it a vital component in many mechanical systems.

Design Features

The double lip seal typically comprises two sealing lips that are strategically positioned to engage the shaft or housing. This design provides a dual barrier against the infiltration of dust, dirt, and other contaminants, which is particularly important in harsh environments. The materials used for these seals often include elastomers like nitrile rubber, fluorocarbon, or silicone, ensuring flexibility, resilience, and resistance to wear and chemicals.

One of the critical aspects of the double lip seal's design is its geometry. The two lips work in conjunction, allowing the seal to maintain integrity even under varying pressures and operational conditions. The primary lip is responsible for sealing against the fluid, while the secondary lip acts as an additional defense against the ingress of contaminants. This combination ensures a longer service life and reduced maintenance, making the double lip seal an efficient choice for manufacturers and engineers.

Applications

Double lip seals find applications across a wide range of industries, including automotive, aerospace, manufacturing, and oil & gas

. In automotive systems, for instance, they are often used in applications such as wheel bearings, engine crankshafts, and transmission components. In these contexts, the double lip seal effectively prevents lubricant leakage and ensures that critical components remain protected from environmental elements.double lip seal

In the aerospace sector, double lip seals are essential in maintaining the integrity of hydraulic systems and fuel tanks. Their ability to function under extreme temperatures and pressures makes them an ideal choice for aircraft applications, where reliability is paramount. The failure of a seal in such systems can lead to catastrophic results, so the use of double lip seals contributes significantly to safety and operational efficiency.

Similarly, in oil and gas applications, these seals are used to protect pumps, compressors, and valves from the corrosive effects of various fluids, ensuring longevity and reducing downtime. The resilient materials from which double lip seals are made can withstand not only high pressures but also the chemical compositions typical of these environments.

Advantages

The advantages of using double lip seals are manifold. Firstly, the two-lip design significantly enhances sealing performance compared to single lip seals. This leads to a reduction in maintenance costs and extends the life expectancy of machinery. Secondly, these seals minimize the risk of fluid leakage, which is crucial in maintaining operational efficiency and environmental compliance.

Moreover, the ability of double lip seals to act as barriers against contaminants means that they can help in maintaining the cleanliness of critical machine elements, thereby enhancing overall reliability. This benefit is particularly crucial in precision applications where even minor contamination can lead to significant performance issues.

Conclusion

In conclusion, the double lip seal is an innovative and highly effective sealing solution that plays a crucial role in various industries. Its thoughtful design, comprising two seals for maximum protection, coupled with the use of durable materials, makes it an indispensable component in a wide array of applications. As industries continue to evolve and demand higher performance and reliability, the importance of effective sealing technologies like double lip seals will only grow. Whether in automotive, aerospace, or industrial machinery, these seals are vital for ensuring operational integrity, efficiency, and safety in a multitude of settings.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories