Oct . 04, 2024 19:55 Back to list

High Temperature Resistant Oil Seals for Enhanced Performance and Longevity in Various Applications

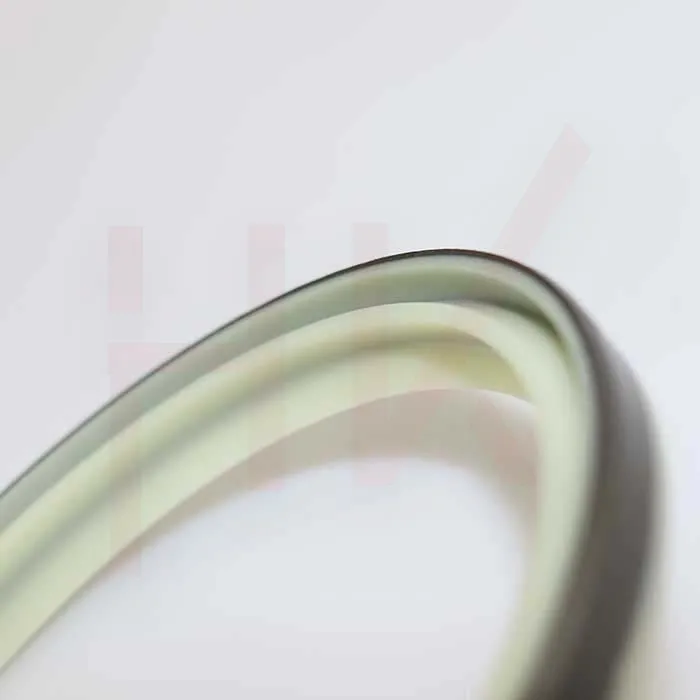

High Temperature Oil Seal An Essential Component for Performance and Longevity

In various industrial applications, the integrity of machinery and equipment is paramount. One critical component that plays a significant role in maintaining this integrity is the high-temperature oil seal. These seals are engineered to withstand extreme temperatures while providing a robust barrier against oil leaks, ensuring that machinery operates smoothly and efficiently.

High Temperature Oil Seal An Essential Component for Performance and Longevity

The primary function of an oil seal is to prevent the escape of lubricants while protecting the machinery from contaminants. When operating at high temperatures, the likelihood of oil breakdown increases, leading to reduced lubrication efficiency and potential damage to components. A high-temperature oil seal helps mitigate these risks by maintaining the integrity of the lubricating film, thereby extending the operational lifespan of the machinery.

high temp oil seal

In addition to their heat resistance, high-temperature oil seals offer excellent resistance to various oils and chemicals, enhancing their reliability in diverse environments. This is particularly important in industries such as automotive manufacturing, where different types of engine oils and lubricants may be present. The ability of these seals to resist wear and deformation under constant exposure to high temperatures and aggressive fluids is crucial for preventing costly downtimes and repairs.

Furthermore, the design of high-temperature oil seals is also instrumental in their performance. Advanced sealing technology, such as lip designs and spring-loaded mechanisms, ensures optimal sealing effectiveness while accommodating thermal expansion and contraction. This adaptability is vital for maintaining a consistent seal even in fluctuating thermal conditions.

In conclusion, high-temperature oil seals are indispensable components in various industrial applications, ensuring optimal performance and longevity of machinery. By effectively preventing oil leaks and resisting high heat and aggressive fluids, these seals contribute to the efficiency and reliability of equipment, making them an essential investment for any operation that prioritizes performance and durability. As industries continue to evolve, the demand for high-performance sealing solutions like high-temperature oil seals will undoubtedly grow, driving innovation in materials and designs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories