Feb . 12, 2025 18:18 Back to list

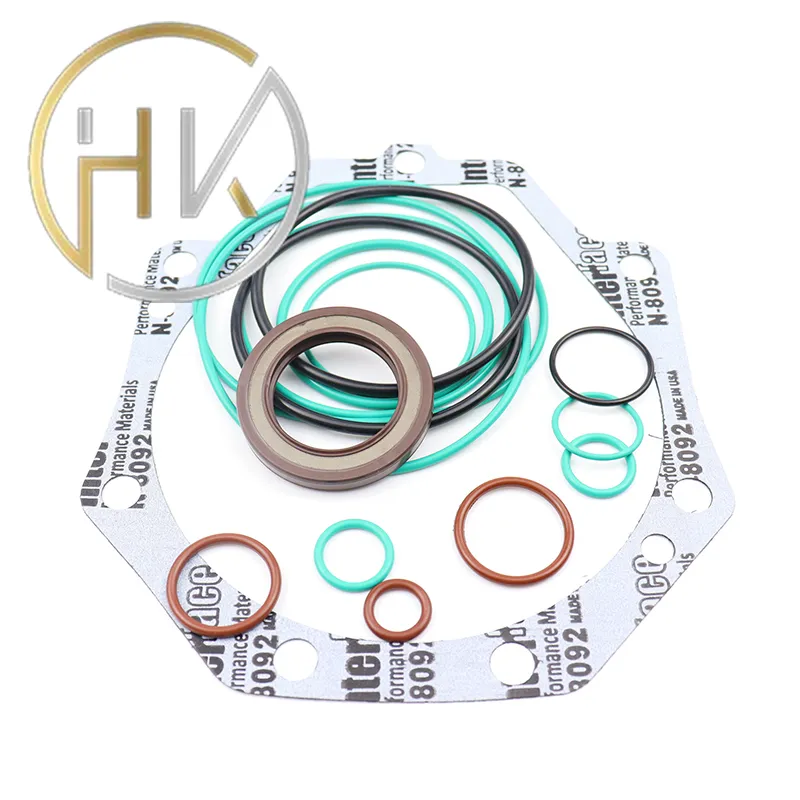

excavator seal kit

The trustworthiness of an excavator’s operational capacity is directly linked to its maintenance regime, wherein the role of seal kits cannot be overstated. Regular inspection and replacement of worn-out seals is integral to maintaining a fluid-sealed environment conducive to excellent hydraulic performance. Seal failures, often resulting from neglect or deterioration over time, can impair hydraulic functions, leading to loss of productivity and elevated maintenance costs. By regularly maintaining seal integrity, operators can prevent hydraulic contamination and ensure the equipment remains in peak form. Perhaps the most compelling reason to invest in a high-quality excavator seal kit is its economic efficiency. With the rising costs of repairs and replacement parts, proactively maintaining your hydraulic seals is a cost-effective strategy. A nominal investment in a superior seal kit can translate into significant savings by enhancing machine uptime and reducing the likelihood of catastrophic failures. To determine the best seal kit for your excavator, consider factors such as the working environment, the age and model of the machinery, and specific operational demands. Experienced operators recognize that harsh working conditions—such as extreme temperatures and abrasive materials—can expedite seal wear. Therefore, selecting a seal kit adept at withstanding these conditions is paramount for sustaining operational efficiency. In summary, excavator seal kits embody a critical component of maintenance strategy, blending engineering prowess with proactive care to ensure machinery reliability. Leveraging decades of industry expertise, authoritative research, and material innovations, they remain foundational to the safe and effective operation of excavators. For professionals committed to excellence in heavy machinery operations, investing in high-quality, model-specific seal kits is a prudent choice that pays dividends through enhanced performance and durability.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories