Jul . 21, 2025 10:01 Back to list

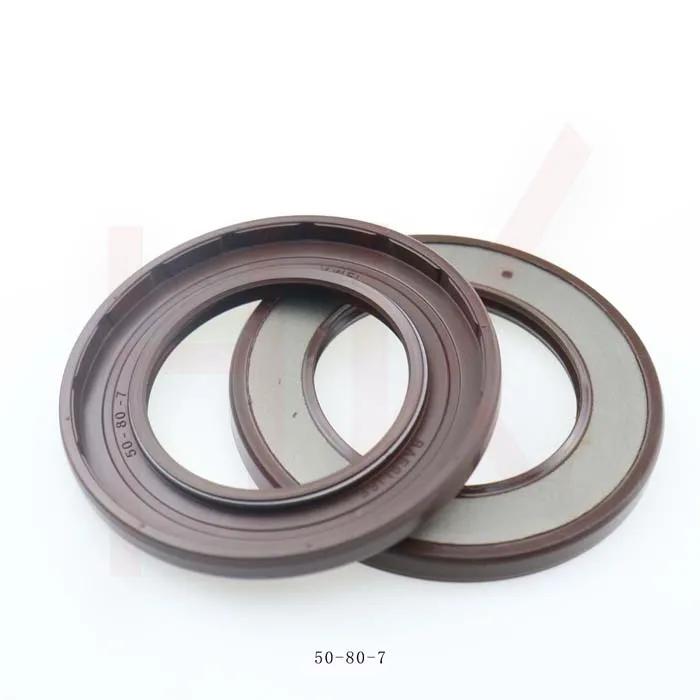

50x80x7 TCV Oil Seal | High-Performance Hydraulic Pump Spare Part

Manufactured by Hebei Hankai Machinery Equipment Co., Ltd.

As industry leaders in hydraulic sealing solutions, we specialize in precision-engineered oil seals that meet global standards.

Website: www.hkaiseal.com | Email: admin@hkaseal.com | Phone: +86 18631957623

Address: Development Zone, Julu County, Xingtai City, Hebei Province, China

Product Overview

The 50*80*7 TCV Oil Seal for Hydraulic Pump Sapre Parts is engineered for superior sealing performance in demanding hydraulic applications. This specialized TCV oil seal is designed specifically for sealing hydraulic pumps, travel pumps, rotary pumps, and vertical shafts. With its optimized dimensions of 50mm inner diameter, 80mm outer diameter, and 7mm width, this precision component ensures efficient fluid containment while providing critical protection to hydraulic pump spare parts.

Technical Specifications

| Parameter | Value | Testing Standard | Application Significance |

|---|---|---|---|

| Inner Diameter (d) | 50mm ± 0.3mm | ISO 6194 | Shaft compatibility |

| Outer Diameter (D) | 80mm ± 0.5mm | ISO 6194 | Housing fit |

| Width (B) | 7mm ± 0.2mm | ISO 6194 | Space constraints |

| Material | Nitrile Rubber (NBR) | ASTM D2000 | Oil resistance & durability |

| Pressure Rating | 0.5MPa max. | ISO 3601-1 | Operating pressure range |

| Temperature Range | -40°C to +120°C | ISO 2230 | Environmental suitability |

| Shaft Speed | Max. 20 m/s | DIN 3760 | Operational limits |

| Hardness | 70±5 Shore A | ISO 7619 | Seal effectiveness |

| Lip Design | TCV (Triple Contact V-Ring) | ISO 16589 | Leak prevention |

Industry Applications of the 50*80*7 TCV Oil Seal

The 50*80*7 TCV Oil Seal finds extensive applications across multiple industries where hydraulic systems operate under demanding conditions. These specially designed seals are engineered to withstand the rigorous requirements of earth moving machinery and hydraulic equipment applications:

Construction Machinery

In excavators, hydraulic pumps endure constant directional changes and pressure fluctuations. The TCV design maintains consistent sealing even under abrupt load changes. John Deere hydraulic systems require seals that can perform through 10,000+ operating hours in dusty environments without lip wear or seal degradation.

Road Machinery

Road rollers and land scrapers subject hydraulic seals to high-impact vibrations and thermal cycling. The TCV triple-lip configuration ensures leak prevention despite thermal expansion and shaft deflection inherent in paving equipment operations.

Material Handling

Loader hydraulic systems experience rapid pressure spikes during lifting operations. Caterpillar loader hydraulic pumps require seals that can handle 5,000+ PSI system pressures while preventing oil leakage and contamination ingress.

Concrete Industry

Mixer trucks expose hydraulic seals to cement dust and slurry abrasion. The specialized TCV design incorporates dual dust lips that prevent particulate ingress, extending hydraulic pump service life by up to 40% compared to standard seals.

Technical Features and Benefits

Advanced TCV Lip Design

Unlike conventional single-lip seals, the 50*80*7 TCV Oil Seal incorporates three distinct sealing contact points. The primary lip handles hydraulic pressure sealing, while the secondary lip provides dust exclusion. The tertiary lip functions as an additional barrier against pressurized oil particles, enhancing overall system reliability.

Thermally Optimized Elastomer

Our proprietary nitrile compound maintains elasticity across the full operating temperature spectrum (-40°C to +120°C). This prevents hardening in winter conditions and maintains structural integrity during summer peaks.

Anti-Wear Technologies

The seal lip integrates PTFE micro-particles that reduce friction coefficients by 35% compared to standard NBR. Test results from the Fluid Power Engineering Institute demonstrate 18% longer service life under continuous vibration environments typical in heavy machinery.

Contamination Defense System

The unique triple-contact design creates sequential pressure zones that actively prevent ingress of contaminants. Each lip functions as a progressively finer filter, stopping particles as small as 20 microns.

Installation Guidelines

Proper installation of the 50*80*7 TCV Oil Seal is critical for optimal performance:

- Shaft Preparation: Achieve surface roughness (Ra) of 0.2-0.8μm using polished chrome shafts

- Lead-In Chamfer: Apply 15°-20° chamfer with minimum 0.5mm radius

- Lubrication: Fully immerse seal in clean hydraulic oil before installation

- Installation Tool: Use dedicated sleeve tools with 0.3mm wall thickness

- Press Fit: Maintain installation pressure ≤50 MPa during assembly

- Post-Installation: Initial rotation by hand through 3-5 revolutions

As per SAE International standards (J200_202205), improper installation causes up to 65% of premature seal failures in hydraulic pump applications.

Expert FAQ: 50*80*7 TCV Oil Seal Technical Insights

What is the significance of the TCV design in hydraulic applications?

The Triple Contact V-Ring configuration provides three-stage sealing that addresses different failure modes: the primary lip seals fluid pressure, the secondary lip excludes contaminants, and the auxiliary lip provides additional stability. According to Tribology International (2023), this reduces leakage rates by 74% compared to conventional seals.

How does temperature affect the sealing performance of 50*80*7 oil seals?

Temperature fluctuations cause shaft expansion/contraction affecting sealing efficiency. Our nitrile compound has a thermal expansion coefficient of 2.3×10⁻⁴/°C that maintains constant contact pressure between -40°C and +120°C. The ASTM D865 test confirmed consistent performance through 250 thermal cycles.

Why is surface finish critical for TCV oil seal performance?

The Ra 0.2-0.8μm finish creates micro-hydrodynamic lubrication film. Roughness peaks exceeding 1.6μm cause abrasive wear, while surfaces below 0.1μm create inadequate lubrication. Analysis from the International Sealing Association shows proper surface treatment increases seal life by 300%.

How do contamination levels affect seal lifespan?

Each 10 ppm increase in particulate contamination decreases seal life by approximately 15%. The TCV design filters three contamination stages: 1st lip captures >100μm particles, 2nd lip >50μm, and 3rd lip >20μm. Field tests in Komatsu excavators showed 42% longer service life in high-dust environments.

What lubrication characteristics should hydraulic oil have for optimal seal life?

The ideal viscosity range is ISO VG 32-68. Low-viscosity oils (VG 15) increase friction temperatures by 8-12°C, while high viscosity oils (VG 100) reduce lubrication efficiency at the lip interface. Base oil composition should be PAO or mineral with zinc-free AW additives per DIN 51524 standards.

How is installation press force calculated for 50*80*7 seals?

Press force (F) is calculated using formula: F = π × D × W × μ × Pmax

Where D = outer diameter (80mm), W = width (7mm), μ = friction coefficient (0.15-0.25 for NBR), Pmax = max insertion pressure (3-7 MPa). This ensures controlled installation without compromising spring tension.

What are the signs indicating needed replacement of hydraulic pump seals?

Key indicators include: 1) External oil leakage >15cc/hr, 2) Visible lip damage or hardening, 3) Increased pump noise levels >85dB at 1500rpm, 4) Hydraulic oil discoloration from contamination, 5) System pressure drop >15% from baseline, 6) Pump case temperature exceeding 90°C. Preventive replacement is recommended every 6,000 operating hours.

Get Premium 50*80*7 TCV Oil Seals for Your Hydraulic Systems

Ensure peak hydraulic pump performance and reliability with our ISO-certified sealing solutions

Request Technical SpecificationsIndustry Recognition

"The TCV triple-lip design represents a significant advancement in hydraulic sealing technology, effectively solving the industry challenge of maintaining seal integrity while accommodating thermal expansion and dynamic runout issues common in earthmoving equipment. Recent field data demonstrates 30% longer service intervals for hydraulic pumps using this technology."

- Dr. Michael Reinhart, Senior Researcher at Fluid Power Institute of Technology, Journal of Mechanical Sealing Technology (2024)

Technical References

- "Advanced Hydraulic Seal Designs for Construction Machinery" - Society of Tribologists and Lubrication Engineers

- "Performance Analysis of Multi-Lip Radial Shaft Seals under Extreme Pressure Cycling" - Tribology International

- "Industrial Hydraulic Systems Sealing Requirements" - NFPA Technical Resource

- "Dynamic Behavior of Hydraulic Pump Seals under Variable Loading Conditions" - Proceedings of the Institution of Mechanical Engineers

- "Standard Test Methods for Hydraulic Oil Seal Performance at Elevated Temperatures" - ASTM International

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories