Th10 . 13, 2024 21:41 Back to list

Understanding Single Acting Piston Seal Functionality and Applications in Various Industries

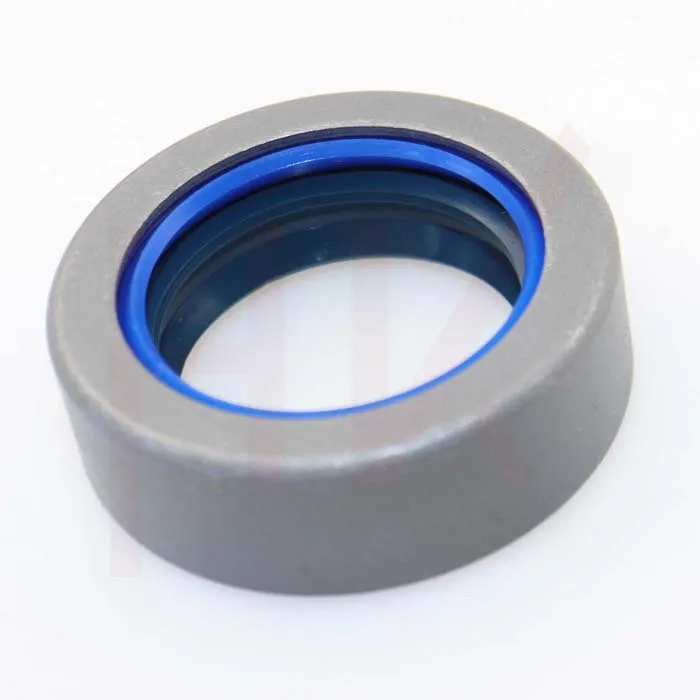

Understanding Single Acting Piston Seals A Comprehensive Overview

In the world of engineering and machinery, seals play a crucial role in ensuring the efficient operation of various equipment. Among the various sealing solutions available, single acting piston seals are particularly prevalent in hydraulic systems. This article aims to explain what single acting piston seals are, their types, applications, and the factors to consider when choosing the right seal for your needs.

What Is a Single Acting Piston Seal?

A single acting piston seal is designed to function effectively in a hydraulic cylinder where the pressure acts on one side of the piston only. Unlike double acting seals, which can seal fluid from both sides, single acting seals offer sealing capability from one direction. This means they are specifically engineered to handle pressure from either the fluid or gas side, but not both simultaneously.

The primary purpose of a single acting piston seal is to prevent hydraulic fluid from leaking out while still allowing the piston to move. This is particularly important in maintaining system pressure and ensuring that the machinery operates smoothly and efficiently.

Types of Single Acting Piston Seals

There are several types of single acting piston seals, each designed for specific applications and environments. The most common include

1. U-Cup Seals These are shaped like a U and are typically used in low to medium pressure applications. Their design offers good sealing properties and easy installation.

2. O-Ring Seals O-rings can be used as single acting seals when placed in grooves. They are versatile and can be found in various applications, ranging from automotive to industrial machinery.

3. V-Rings V-rings are marked by their triangular cross-section and are effective in high-speed applications. They can accommodate shaft misalignment and provide reliable sealing.

4. Cup Seals These seals have a cup-like shape and are designed to operate under higher pressures. They tend to provide excellent sealing capabilities in dynamic applications.

Applications of Single Acting Piston Seals

Single acting piston seals find a wide range of applications across various industries. Some common uses include

- Hydraulic Cylinders They are widely used in hydraulic cylinders found in construction machinery, agriculture equipment, and manufacturing systems.

single acting piston seal

- Aerospace In aircraft hydraulic systems, seals must endure varying pressures and are critical for ensuring safe and reliable performance.

- Automotive Single acting seals are essential in braking systems and hydraulic lifts, contributing to efficient vehicle operation.

- Marine They are utilized in hydraulic steering systems and winches, where they prevent fluid leaks in challenging marine environments.

These seals are essential components in systems that require reliable performance under pressure while minimizing the risk of fluid leakage.

Factors to Consider When Choosing Single Acting Piston Seals

Selecting the right single acting piston seal for your application is vital for optimal performance. Here are key factors to consider

1. Pressure and Temperature Understand the operating pressure and temperature ranges. Ensure your seal can withstand these conditions without degrading.

2. Material Compatibility Ensure that the sealing material is compatible with the fluid it will be exposed to, whether it be oil, water, or gas, to prevent chemical degradation.

3. Dynamic vs. Static Applications Consider whether the seal will be in a dynamic environment (where it moves) or static (where it remains still). This can influence the type of seal material and design you choose.

4. Installation Space Consider the physical dimensions of the installation space. Some seals may require specific housing dimensions or installation techniques.

5. Lifecycle and Reliability Assess the required lifespan of the seal and the operating conditions. It’s important to choose a seal that can endure the expected lifecycle for the specific application to minimize maintenance and downtime.

Conclusion

Single acting piston seals are fundamental components in various applications across multiple industries. By understanding their types, their applications, and the critical factors to consider for selection, engineers and technicians can ensure that they choose the right sealing solution for their specific needs. Proper selection and maintenance of these seals can lead to enhanced efficiency, reduced leakage, and extended equipment life, thus contributing to safer and more reliable industrial operations.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories